Are you gearing up for a career in Golf Ball Molder? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Golf Ball Molder and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

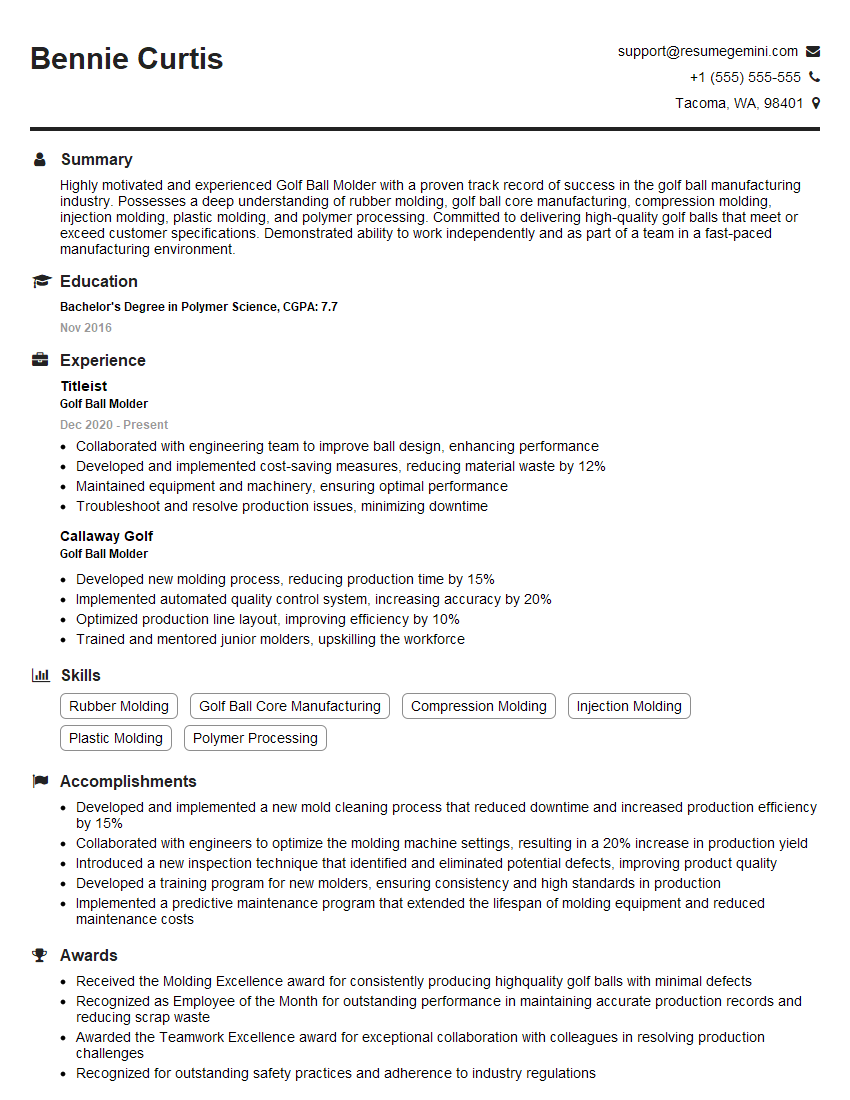

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Golf Ball Molder

1. Explain the process of golf ball molding.

The process of golf ball molding involves several stages:

- Mold preparation: Preparing the mold by cleaning and applying a release agent.

- Material preparation: Weighing and mixing the raw materials to create the golf ball compound.

- Injection molding: Injecting the molten compound into the mold cavity under high pressure.

- Curing: Heating the mold to cure the compound and form the golf ball shape.

- Deflashing: Removing excess material from the golf balls after molding.

- Inspection: Checking the golf balls for quality and compliance with specifications.

2. What are the key parameters to monitor and control during the injection molding process?

Process Parameters

- Injection pressure

- Injection speed

- Mold temperature

- Cycle time

Material Parameters

- Melt temperature

- Viscosity

- Crystallinity

3. How do you ensure the quality of the molded golf balls meet industry standards?

Ensuring quality involves:

- Raw material inspection: Checking incoming materials for conformity.

- Process control: Monitoring and adjusting process parameters to maintain consistency.

- In-process inspection: Inspecting golf balls during molding to identify defects.

- Final inspection: Conducting thorough inspections after molding, including dimensional measurements, surface finish, and performance testing.

4. What are the different types of defects that can occur during golf ball molding and how do you prevent them?

Common defects include:

- Sink marks: Material shrinkage causing depressions in the surface. Prevented by optimizing injection pressure and mold temperature.

- Flash: Excess material around the edges. Prevented by proper mold design and injection parameters.

- Bubbles: Air trapped in the material. Prevented by proper material degassing and injection process.

- Warping: Distortion of the golf ball shape. Prevented by uniform mold cooling and annealing.

5. How do you handle troubleshooting and maintenance of golf ball molding equipment?

Troubleshooting involves:

- Identifying the problem and its potential causes.

- Analyzing data and performing diagnostics.

- Implementing corrective actions and verifying results.

Maintenance includes:

- Regular cleaning and lubrication.

- Replacing worn or damaged parts.

- Calibrating and adjusting equipment.

6. How do you stay updated with the latest advancements in golf ball molding technology?

Staying updated involves:

- Attending industry conferences and workshops.

- Reading technical publications and journals.

- Collaborating with colleagues and industry experts.

7. What are the challenges you face as a Golf Ball Molder and how do you overcome them?

Challenges include:

- Material variability: Managing variations in raw material properties to ensure consistent molding results.

- Process optimization: Balancing process parameters to achieve both efficiency and quality.

- Troubleshooting: Identifying and resolving issues promptly to minimize downtime.

Overcoming challenges requires:

- Technical expertise and problem-solving skills.

- Strong communication and teamwork.

- A commitment to continuous improvement.

8. What is your experience with different types of golf ball molding machines?

Experience with different machines includes:

- Vertical injection molding machines: Machines with a vertical clamping unit and injection unit.

- Horizontal injection molding machines: Machines with a horizontal clamping unit and injection unit.

- Rotary injection molding machines: Machines with a rotating mold table.

9. How do you ensure the efficiency and productivity of the molding operation?

Ensuring efficiency and productivity involves:

- Process optimization: Optimizing process parameters to reduce cycle time and material waste.

- Preventive maintenance: Regularly servicing and maintaining equipment to minimize downtime.

- Operator training: Providing training to operators to ensure proper machine operation and troubleshooting.

10. What are the safety protocols you follow during golf ball molding operations?

Safety protocols include:

- Wearing appropriate personal protective equipment (PPE).

- Following lockout/tagout procedures.

- Maintaining a clean and organized work area.

- Being aware of potential hazards and taking precautions to mitigate risks.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Golf Ball Molder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Golf Ball Molder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Golf Ball Molders are responsible for operating machines that mold golf balls. They ensure that the balls meet specifications for size, weight, and hardness. They also perform quality checks and make adjustments to the molding process as needed.

1. Operate molding machines

Golf Ball Molders use a variety of machines to mold golf balls. These machines include injection molding machines, compression molding machines, and casting machines. Molders must be able to operate these machines safely and efficiently.

2. Inspect golf balls

Molders inspect golf balls for defects such as cracks, scratches, and dents. They also check the balls’ size, weight, and hardness to ensure that they meet specifications..

3. Make adjustments to the molding process

Molders make adjustments to the molding process as needed to ensure that the golf balls meet specifications. These adjustments may include changing the temperature of the molding machine, the pressure of the molding machine, or the type of mold used.

4. Maintain molding equipment

Molders maintain the molding equipment to ensure that it is operating properly. This may include cleaning the machines, lubricating the machines, and replacing worn parts.

Interview Tips

Preparing for an interview can be a daunting task, but there are a few things you can do to increase your chances of success.

1. Research the company and the position

Before you go on an interview, it is important to research the company and the position you are applying for. This will help you understand the company’s culture, values, and goals. It will also help you understand the specific requirements of the position.

2. Practice answering common interview questions

There are a number of common interview questions that you are likely to be asked. It is important to practice answering these questions in advance so that you can deliver your answers confidently and clearly.

3. Dress professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing a suit or business casual attire.

4. Be on time

Punctuality is important, so be sure to arrive on time for your interview. If you are running late, call the interviewer to let them know.

5. Be prepared to ask questions

At the end of the interview, the interviewer will likely ask you if you have any questions. This is your chance to learn more about the company and the position. It is also a good opportunity to show the interviewer that you are interested in the job.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Golf Ball Molder interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.