Feeling lost in a sea of interview questions? Landed that dream interview for Goodyear Welter but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Goodyear Welter interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

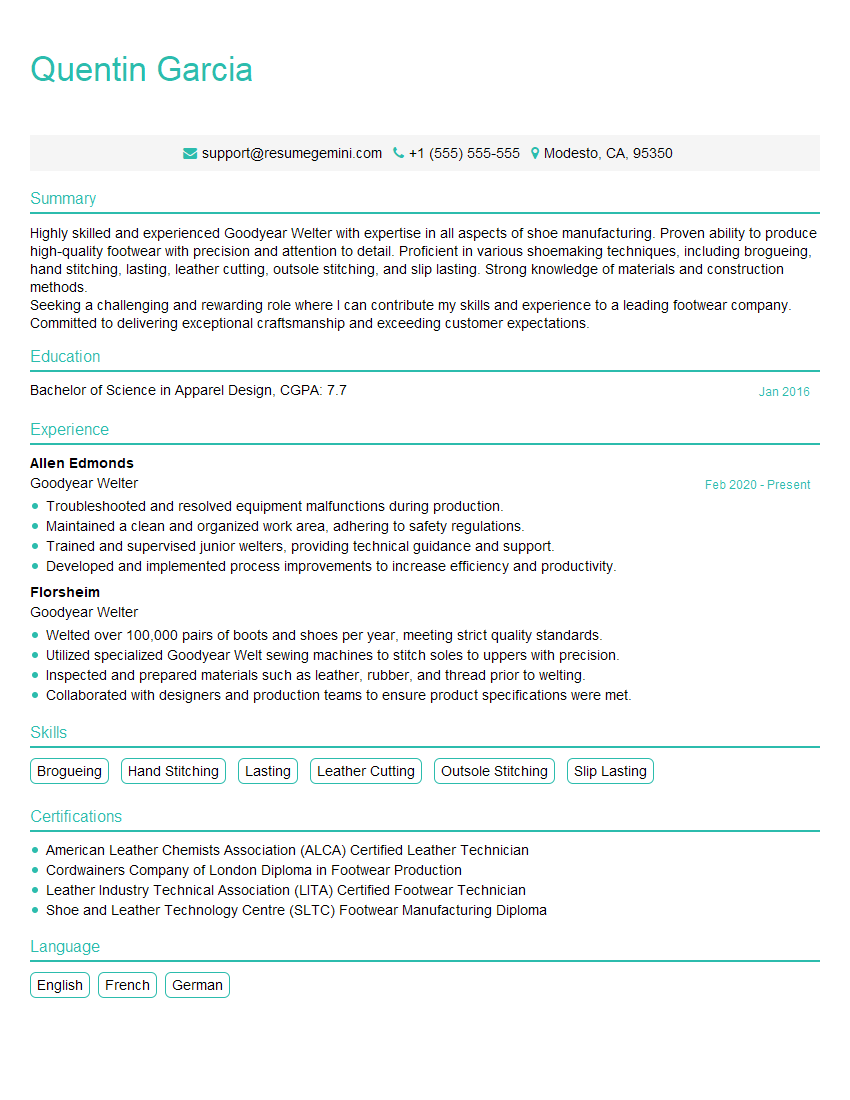

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Goodyear Welter

1. Describe the process of preparing a shoe upper for Goodyear welting.

The process of preparing a shoe upper for Goodyear welting involves several key steps:

- Trimming the upper: Excess material around the edges of the upper is trimmed away to ensure a precise fit when it is attached to the welt.

- Skiving the edges: The edges of the upper are thinned down using a skiving machine to create a smooth and beveled surface for the welt to adhere to.

- Applying edge dressing: A special adhesive called edge dressing is applied to the beveled edges of the upper to help the welt adhere more securely.

2. Explain the steps involved in attaching the welt to the shoe upper.

Attaching the welt to the shoe upper requires precision and attention to detail:

- Positioning the welt: The welt is placed around the perimeter of the upper, ensuring that it aligns correctly with the skived edges.

- Applying cement: Adhesive cement is applied to the welt and the skived edges of the upper.

- Pressing the welt: The welt is pressed firmly against the upper using a heated mold or press, which activates the cement and creates a strong bond.

3. How do you ensure proper alignment and tension during the Goodyear welting process?

Proper alignment and tension are crucial for a successful Goodyear welt:

- Alignment: Throughout the process, careful attention is paid to ensuring that the upper, welt, and outsole are aligned correctly to prevent any misalignment or distortion.

- Tension: Tension is applied to the welt during pressing to create a tight and secure bond between the upper and sole. This tension is controlled by adjusting the pressure and dwell time of the press.

4. What are the common challenges encountered during Goodyear welting and how do you overcome them?

Goodyear welting presents certain challenges, but with experience and expertise, these can be effectively addressed:

- Creasing or wrinkling: Careful handling and proper application of heat can prevent or minimize creases and wrinkles in the leather during the molding process.

- Adhesive failure: Ensuring that the correct adhesive is used and properly applied, along with adequate pressing, can prevent adhesive failure.

- Misalignment: Paying close attention to alignment during each step of the process helps avoid misalignment between the upper, welt, and sole.

5. Describe the different types of materials used in Goodyear welting and their properties.

Goodyear welting involves the use of various materials with specific properties:

- Leather: Leathers with a tight grain and firm temper are preferred for uppers and welts, as they provide durability and strength.

- Welt material: Welts can be made from leather, rubber, or synthetic materials, each offering varying degrees of flexibility, durability, and water resistance.

- Outsole: Outsoles are typically made from leather, rubber, or a combination of materials, providing traction, durability, and comfort.

6. Explain the advantages and disadvantages of Goodyear welting compared to other shoemaking methods.

Goodyear welting has both advantages and disadvantages:

Advantages:

- Durability: The robust construction provides exceptional durability and longevity.

- Water resistance: The welt acts as a barrier, enhancing water resistance.

- Resoleability: Goodyear welted shoes can be resoled multiple times, extending their lifespan.

Disadvantages:

- Labor-intensive: Goodyear welting requires skilled craftsmanship, making it more labor-intensive than other methods.

- Cost: The complexity and craftsmanship involved in Goodyear welting contribute to higher production costs.

- Weight: The multiple layers of materials can add weight to the shoe.

7. How do you handle customer inquiries or complaints related to Goodyear welted shoes?

Customer satisfaction is paramount:

- Listening attentively: Understanding the customer’s concerns and listening attentively to their feedback is essential.

- Inspecting the shoes: A thorough inspection of the shoes is necessary to identify any potential issues or defects.

- Explaining the process: Educating the customer about the Goodyear welting process and the unique characteristics of the shoes can help address their concerns.

- Offering solutions: If necessary, offering repair or replacement options while maintaining a positive and professional demeanor is crucial.

8. Describe the latest advancements or trends in Goodyear welting technology.

Goodyear welting continues to evolve:

- Automation: New technologies are being explored to automate certain aspects of the welting process, improving efficiency.

- Sustainable materials: There is a growing emphasis on using sustainable and eco-friendly materials in Goodyear welt construction.

- Design innovation: Modern designs are incorporating creative uses of materials and colors in Goodyear welted shoes, combining tradition with innovation.

9. Explain how you stay up-to-date with the latest techniques and best practices in Goodyear welting.

Keeping up-to-date is essential:

- Industry events: Attending industry events, workshops, and conferences provides opportunities to learn from experts and discover new techniques.

- Online resources: Utilizing online platforms, forums, and webinars to access the latest information and connect with peers.

- Collaboration: Engaging with other Goodyear welters and shoemakers to exchange knowledge and ideas.

10. What are your goals and aspirations for your career as a Goodyear Welter?

Goals and aspirations:

- Mastering the craft: Continuously refining skills and becoming an expert in the art of Goodyear welting.

- Innovation and design: Exploring new materials and techniques to push the boundaries of Goodyear welting.

- Sharing knowledge: Mentoring and training aspiring Goodyear welters, passing on the tradition and skills.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Goodyear Welter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Goodyear Welter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Goodyear Welter, you will be responsible for a variety of tasks related to the production of Goodyear welted footwear.

1. Operating Goodyear Welting Machine

You will be responsible for operating the Goodyear welting machine, which is used to attach the welt to the upper and outsole of the shoe.

- Ensure that the machine is properly set up and calibrated.

- Load the upper, welt, and outsole into the machine.

- Operate the machine to stitch the welt to the upper and outsole.

2. Inspecting Welts

You will be responsible for inspecting the welts to ensure that they are properly stitched and that there are no defects.

- Visually inspect the welts for any defects.

- Use a magnifying glass to inspect the welts for any small defects.

- Repair any defects that are found.

3. Preparing and Maintaining Equipment

You will be responsible for preparing and maintaining the equipment that is used in the Goodyear welting process.

- Clean and lubricate the Goodyear welting machine.

- Sharpen the knives that are used to cut the welt.

- Replace any worn or damaged parts.

4. Adhering to Safety Regulations

You will be responsible for adhering to all safety regulations that are related to the Goodyear welting process.

- Wear appropriate safety gear.

- Follow all safety procedures.

- Report any safety hazards to your supervisor.

Interview Tips

Here are some tips to help you ace your interview for a Goodyear Welter position:

1. Research the Company and the Position

Before your interview, take the time to research the company and the position you are applying for. This will help you understand the company’s culture, values, and goals, and it will also help you understand the specific requirements of the position.

2. Prepare Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” Prepare your answers to these questions in advance so that you can deliver them confidently and concisely.

3. Showcase Your Skills and Experience

Make sure to highlight your skills and experience that are relevant to the Goodyear Welter position. For example, if you have experience operating a Goodyear welting machine, be sure to mention this in your interview.

4. Be Enthusiastic and Positive

Employers are looking for candidates who are enthusiastic and positive about the opportunity to work for their company. Be sure to show your enthusiasm during your interview, and be positive about your ability to perform the job.

5. Ask Questions

At the end of your interview, be sure to ask the interviewer any questions that you have about the position or the company. This shows that you are interested in the opportunity and that you are taking the interview seriously.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Goodyear Welter interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!