Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Grading Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

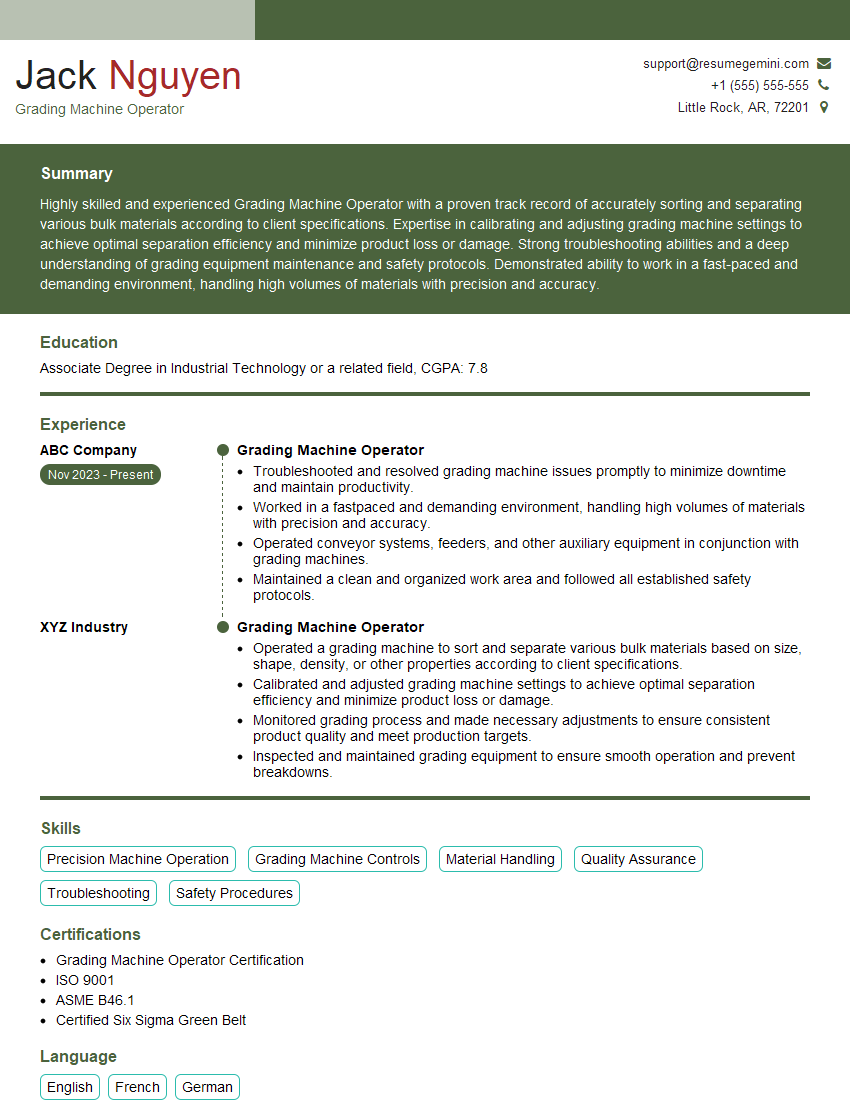

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Grading Machine Operator

1. What is the purpose of a grading machine?

The purpose of a grading machine is to separate agricultural products based on size, shape, weight, or color. Grading machines are used in various industries, including food processing, agriculture, and mining.

2. What are the different types of grading machines?

There are several types of grading machines, including:

- Size grading machines separate products based on their size. These machines use screens or rollers to separate products into different sizes.

- Shape grading machines separate products based on their shape. These machines use optical sensors or lasers to identify and separate products of different shapes.

- Weight grading machines separate products based on their weight. These machines use scales to weigh products and separate them into different weight categories.

- Color grading machines separate products based on their color. These machines use optical sensors or cameras to identify and separate products of different colors.

3. What are the key factors to consider when selecting a grading machine?

The key factors to consider when selecting a grading machine include:

- The type of product being graded

- The desired grading criteria (size, shape, weight, or color)

- The capacity of the machine

- The accuracy and reliability of the machine

- The cost of the machine

4. How do you calibrate a grading machine?

The calibration of a grading machine is a critical step to ensure that the machine is accurately sorting products. The calibration process involves adjusting the machine’s settings to match the desired grading criteria. This may involve adjusting the screen size, the weight settings, or the color sensors.

5. What are the common problems that can occur with grading machines?

Some common problems that can occur with grading machines include:

- Misgrading products

- Damage to products

- Mechanical breakdowns

- Electrical problems

6. How do you troubleshoot and repair common problems with grading machines?

Troubleshooting and repairing common problems with grading machines requires a combination of technical skills and experience. The specific troubleshooting and repair steps will vary depending on the type of problem.

7. What are the safety precautions that should be taken when operating a grading machine?

Operating a grading machine can involve potential hazards. It is important to follow all safety precautions, including:

- Wearing appropriate safety gear, such as gloves, safety glasses, and earplugs

- Keeping the work area clean and free of debris

- Never reaching into the machine while it is running

- Following lockout/tagout procedures when performing maintenance or repairs

8. How do you maintain a grading machine to ensure optimal performance?

Regular maintenance is essential to ensure optimal performance and extend the lifespan of a grading machine. Maintenance tasks may include:

- Cleaning the machine regularly

- Lubricating moving parts

- Inspecting the machine for wear and damage

- Performing regular calibrations

9. What are the latest advancements in grading machine technology?

The grading machine industry is constantly evolving with new advancements in technology. Some of the latest advancements include:

- The use of artificial intelligence (AI) to improve grading accuracy and efficiency

- The development of more compact and portable grading machines

- The integration of grading machines with other automated systems, such as conveyor belts and packaging machines

10. How do you stay up-to-date with the latest trends and advancements in grading machine technology?

To stay up-to-date with the latest trends and advancements in grading machine technology, you can:

- Attend industry conferences and trade shows

- Read industry publications and online resources

- Network with other professionals in the field

- Participate in online forums and discussion groups

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Grading Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Grading Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Grading Machine Operators are in charge of overseeing the operation and maintenance of grading machines. They ensure that machines are running smoothly and efficiently, and that graded materials meet quality standards. Here are the key responsibilities of a Grading Machine Operator:1. Machine Operation

Grading Machine Operators are responsible for starting up, shutting down, and monitoring the operation of grading machines. They must ensure that the machine is running at the correct speed and settings, and that it is properly calibrated and maintained. They are also responsible for troubleshooting any problems that occur with the machine.

2. Material Grading

Grading Machine Operators are responsible for grading materials according to various criteria, such as size, shape, and quality. They must ensure that the graded materials meet the required specifications and standards. They may also be responsible for blending different materials to create a desired mix.

3. Equipment Maintenance

Grading Machine Operators are responsible for maintaining the grading machine and associated equipment. They must keep the machine clean and lubricated, and they must perform regular inspections and repairs. They must also follow all safety procedures and regulations.

4. Record Keeping

Grading Machine Operators are responsible for keeping accurate records of the grading process. They must record the materials being graded, the settings of the machine, and the results of the grading. They must also document any maintenance or repairs performed on the machine.

Interview Preparation Tips

To ace an interview for a Grading Machine Operator position, candidates should be prepared to discuss their experience and skills in the following areas:1. Machine Operation

Candidates should be familiar with the operation of various types of grading machines. They should be able to discuss their experience in setting up, operating, and troubleshooting grading machines. They should also be familiar with the safety procedures and regulations associated with operating grading machines.

Example Question: “Describe your experience in operating grading machines. What types of machines have you worked with?”

2. Material Grading

Candidates should be familiar with the different methods of grading materials. They should be able to discuss their experience in grading materials according to various criteria, such as size, shape, and quality. They should also be familiar with the different types of materials that can be graded, and the standards and specifications that apply to each type of material.

Example Question: “Describe your experience in grading materials. What types of materials have you graded, and what criteria have you used to grade them?”

3. Equipment Maintenance

Candidates should be familiar with the maintenance requirements of grading machines. They should be able to discuss their experience in performing regular inspections, lubrication, and repairs on grading machines. They should also be familiar with the safety procedures and regulations associated with maintaining grading machines.

Example Question: “Describe your experience in maintaining grading machines. What types of maintenance tasks have you performed?”

4. Record Keeping

Candidates should be familiar with the importance of record keeping for grading machines. They should be able to discuss their experience in keeping accurate records of the grading process, including the materials being graded, the settings of the machine, and the results of the grading. They should also be familiar with the different types of records that are required for grading machines.

Example Question: “Describe your experience in keeping records for grading machines. What types of records have you kept, and how have you used them?”

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Grading Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!