Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Graduating Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

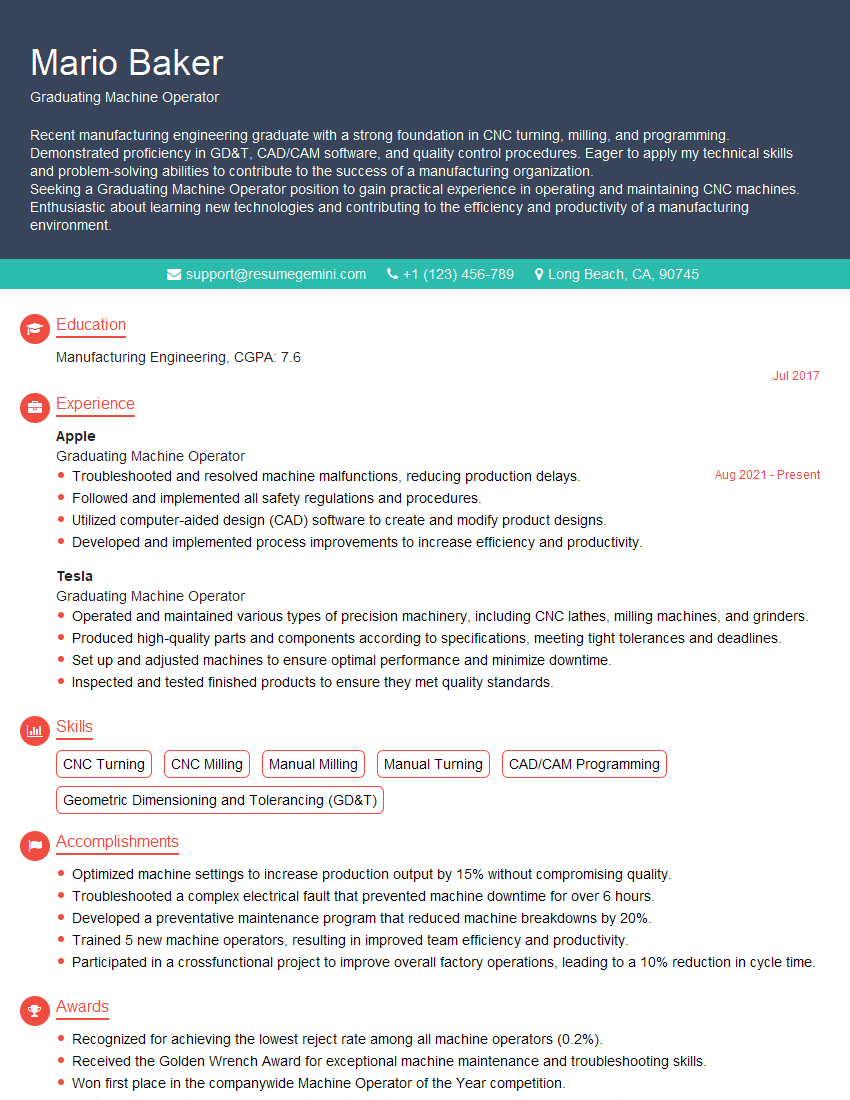

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Graduating Machine Operator

1. What is the importance of setting up a machine correctly?

The correct setup of a machine is crucial for several reasons:

- Safety: Improper setup can lead to accidents and injuries.

- Quality: Incorrect setup can result in defective or subpar products.

- Efficiency: Optimal setup ensures maximum production output and minimizes downtime.

- Tool life: Correct setup extends the lifespan of cutting tools and other machine components.

- Energy consumption: Efficient setup optimizes energy usage.

2. Explain the different types of cutting tools used in machining.

Single-point cutting tools

- Turning tools: Used for cutting external and internal cylindrical surfaces.

- Boring tools: Used for enlarging existing holes or creating new ones.

- Facing tools: Used for creating flat surfaces perpendicular to the axis of rotation.

Multi-point cutting tools

- Milling cutters: Used for cutting a variety of shapes and profiles.

- Drilling tools: Used for creating holes.

- Reaming tools: Used for finishing holes to precise dimensions.

3. What are the safety precautions to be taken when operating a machine?

- Wear appropriate safety gear, such as safety glasses, gloves, and earplugs.

- Inspect the machine and ensure it is in good working condition.

- Clear the work area of any obstacles or loose materials.

- Securely clamp the workpiece to prevent it from moving during machining.

- Never operate a machine while under the influence of alcohol or drugs.

4. How do you troubleshoot common machine malfunctions?

- Identify the symptom of the malfunction.

- Check for any loose connections or damaged components.

- Refer to the machine’s manual for specific troubleshooting procedures.

- If unable to resolve the issue, contact a qualified technician.

5. What are the different types of materials that can be machined?

- Metals: Ferrous (e.g., steel, cast iron) and non-ferrous (e.g., aluminum, copper).

- Plastics: Thermoplastics (e.g., ABS, polycarbonate) and thermosets (e.g., fiberglass, epoxy).

- Wood: Hardwoods (e.g., oak, maple) and softwoods (e.g., pine, fir).

- Composites: Combinations of different materials (e.g., carbon fiber reinforced plastic).

6. What is the purpose of a coolant in machining?

- Lubrication: Reduces friction between the cutting tool and the workpiece.

- Cooling: Dissipates heat generated during machining, preventing thermal damage to the tool and workpiece.

- Chip removal: Flushes away metal chips from the cutting zone.

- Corrosion protection: Prevents rust and corrosion on the workpiece.

7. What are the advantages of Computer Numerical Control (CNC) machines?

- Increased accuracy and precision.

- Reduced setup time and labor costs.

- Improved production consistency.

- Ability to produce complex shapes and geometries.

- Enhanced flexibility for different machining operations.

8. Can you describe the different types of machine controls?

- Manual controls: Operated directly by the machine operator.

- CNC controls: Computerized controls that interpret G-codes and M-codes to automate machine movements.

- PLC controls: Programmable logic controllers that use ladder logic to control machine sequences.

- HMI controls: Human-machine interfaces that provide a graphical user interface for machine operation.

9. What is the importance of preventive maintenance for machines?

- Extends machine lifespan.

- Reduces downtime and production losses.

- Improves machine safety and reliability.

- Optimizes machine performance and efficiency.

- Reduces maintenance costs in the long run.

10. What are the key qualities of an effective machine operator?

- Mechanical aptitude and problem-solving skills.

- Attention to detail and accuracy.

- Strong work ethic and responsibility.

- Ability to work independently and as part of a team.

- Understanding of machining principles and safety protocols.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Graduating Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Graduating Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Graduating Machine Operator is responsible for operating a variety of machines in a manufacturing environment. Key job responsibilities include:1. Machine Operation

Setting up, operating, and monitoring machines, ensuring that they are functioning properly and producing quality products.

- Following instructions and work orders

- Inspecting raw materials

2. Maintenance and Troubleshooting

Performing basic maintenance tasks, such as cleaning, lubricating, and adjusting machines; identifying and resolving minor operating problems.

- Replacing worn or damaged parts

- Reporting any issues to supervisors

3. Quality Control

Inspecting products for defects and ensuring that they meet quality standards; identifying and correcting any discrepancies.

- Using measuring tools and gauges

- Adhering to safety regulations

4. Production

Meeting production targets and deadlines; ensuring that machines are running efficiently and maximizing output.

- Loading and unloading materials

- Keeping work area clean and organized

Interview Tips

To prepare for an interview for a Graduating Machine Operator position, consider the following tips:1. Research the Company and the Position

Familiarize yourself with the company’s website, industry, and products. Understand the specific responsibilities and requirements of the position you are applying for.

- Read job descriptions carefully

- Check company reviews and news articles

2. Prepare to Discuss Your Skills and Experience

Highlight your relevant skills and experience, especially those that are directly related to the job responsibilities. Use examples to demonstrate your abilities.

- Quantify your accomplishments using numbers

- Practice describing your experience in a clear and concise manner

3. Practice Common Interview Questions

Prepare for common interview questions, such as why you are interested in the position, what your strengths and weaknesses are, and why you believe you are the best candidate for the job.

- Use the STAR method to answer behavioral questions

- Tailor your answers to the specific job and company

4. Dress Professionally and Arrive on Time

Make a good first impression by dressing professionally and arriving on time for your interview. Be polite and respectful to everyone you meet, including the receptionist and other employees.

- Wear business casual attire

- Be on time or even arrive a few minutes early

Next Step:

Now that you’re armed with the knowledge of Graduating Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Graduating Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini