Are you gearing up for a career in Grain Combiner? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Grain Combiner and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

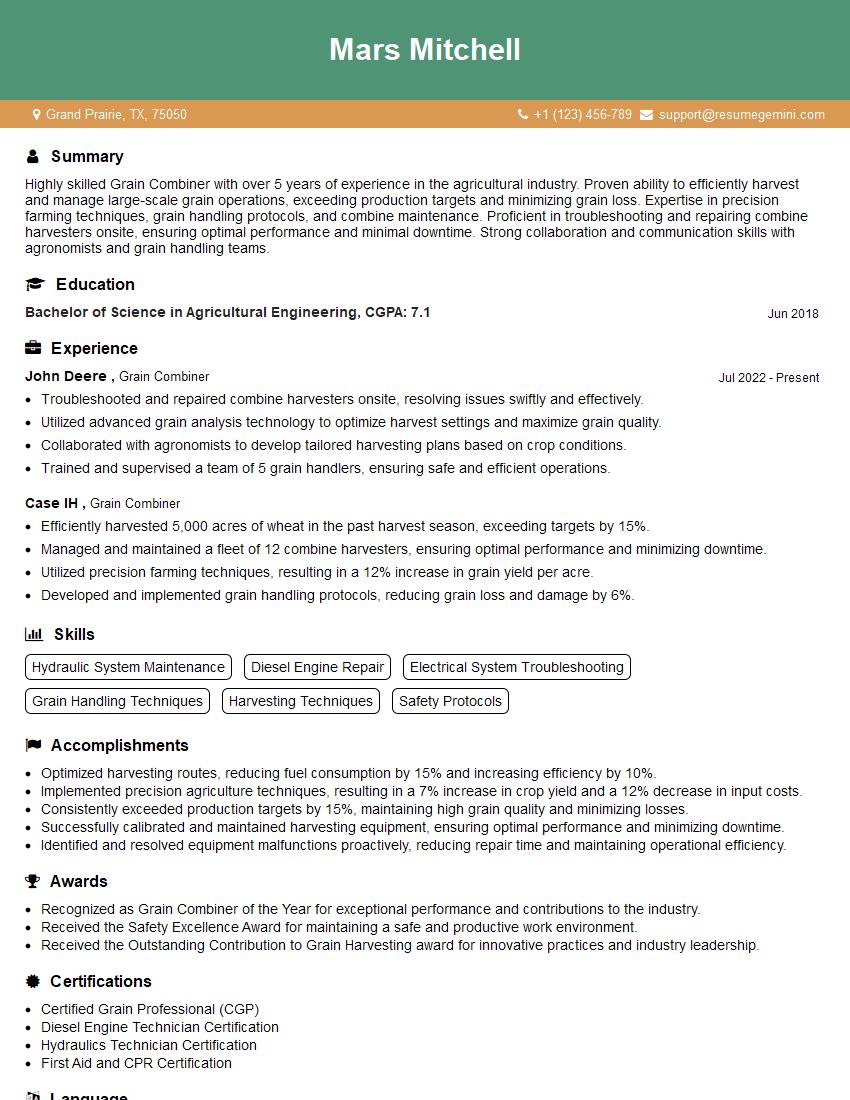

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Grain Combiner

1. What are the major components of a grain combine?

The major components of a grain combine include:

- Header or cutterbar

- Reel

- Auger

- Thresher

- Cleaning system

- Grain tank

- Unloading auger

- Engine and transmission

2. How does a grain combine operate?

Cutting and feeding

- The header or cutterbar cuts the grain crop.

- The reel helps guide the crop into the auger.

- The auger conveys the crop to the thresher.

Threshing and cleaning

- The thresher separates the grain from the straw.

- The cleaning system removes chaff, dust, and other impurities from the grain.

Grain handling

- The cleaned grain is collected in the grain tank.

- The unloading auger empties the grain tank into a truck or other storage device.

3. What are the different types of grain combines?

The three main types of grain combines are:

- Conventional combines

- Axial-flow combines

- Rotary combines

4. What are the advantages and disadvantages of different types of grain combines?

Conventional combines

- Advantages: Higher grain quality, less grain damage, more versatile

- Disadvantages: Slower, more complex, more expensive

Axial-flow combines

- Advantages: Faster, simpler, less expensive

- Disadvantages: Lower grain quality, more grain damage, less versatile

Rotary combines

- Advantages: High capacity, can handle wet or tough crops

- Disadvantages: Lower grain quality, more grain damage, more expensive

5. What are the key factors to consider when selecting a grain combine?

The key factors to consider when selecting a grain combine include:

- Crop type and conditions

- Field size and terrain

- Budget

- Operator experience and preferences

6. How do you maintain and troubleshoot a grain combine?

Regular maintenance and troubleshooting are crucial to ensure the optimal performance and longevity of a grain combine. Here are some key practices:

- Conduct regular inspections to identify potential issues

- Clean and lubricate components as per the manufacturer’s recommendations

- Check and adjust settings to optimize performance

- Troubleshoot and resolve any issues that arise during operation

7. What are the safety precautions to observe when operating a grain combine?

Operating a grain combine involves potential hazards, and adhering to safety precautions is paramount. Here are some key guidelines:

- Wear appropriate personal protective equipment (PPE)

- Inspect the combine thoroughly before each use

- Be aware of surroundings and potential hazards

- Follow proper operating procedures

- Never attempt repairs or adjustments while the combine is running

8. How do you optimize the performance of a grain combine?

Optimizing the performance of a grain combine requires attention to various factors. Here are some key strategies:

- Properly adjust settings for the specific crop and conditions

- Ensure regular maintenance and lubrication

- Monitor performance and make adjustments as needed

- Use high-quality fuel and lubricants

- Train operators on best practices

9. What are the emerging trends and technologies in grain combine design and operation?

The grain combine industry is constantly evolving, with new technologies and innovations emerging. Here are some notable trends:

- Increased automation and use of precision farming techniques

- Development of more efficient and environmentally friendly combines

- Integration of sensors and data analytics for improved performance monitoring and optimization

- Remote monitoring and control capabilities

10. How do you stay updated with the latest advancements in grain combine technology?

Staying updated with the latest advancements in grain combine technology is important for continuous improvement and optimization. Here are some effective methods:

- Attend industry conferences and exhibitions

- Read trade publications and technical journals

- Network with other professionals in the field

- Consult with manufacturers and experts

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Grain Combiner.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Grain Combiner‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Grain Combiners play a crucial role in the harvesting process, operating specialized machinery to efficiently collect and separate grain from crops. They are responsible for operating and maintaining combine harvesters, ensuring optimal performance and efficient grain handling throughout the operation.

1. Combine Operation

Grain Combiners are skilled in maneuvering and operating combine harvesters. They set up and adjust the machine’s settings to match the crop conditions, ensuring optimal grain separation and minimizing losses.

- Operate combine harvesters to cut, thresh, and clean grain

- Adjust combine settings based on crop conditions and yield expectations

2. Grain Handling

Grain Combiners are responsible for handling the harvested grain safely and efficiently. They monitor grain quality, ensuring it meets standards, and work to prevent damage or contamination.

- Monitor grain quality and make adjustments to improve it

- Unload grain into trucks or storage bins

3. Machine Maintenance

Grain Combiners are responsible for maintaining and repairing the combine harvesters. They conduct regular inspections, identify potential issues, and perform necessary repairs to keep the machinery in optimal operating condition.

- Perform routine maintenance on combine harvesters

- Diagnose and repair mechanical issues

4. Safety and Efficiency

Grain Combiners prioritize safety and efficiency in their work. They follow established safety protocols, wear appropriate protective gear, and maintain a clean and organized work environment. They also strive to optimize harvesting efficiency, minimizing downtime and maximizing productivity.

- Follow safety protocols and wear appropriate protective gear

- Maintain a clean and organized work environment

Interview Tips

To help candidates ace their interview for a Grain Combiner position, here are some useful preparation tips:

1. Research the Company and Role

Candidates should thoroughly research the company where they are applying, including its size, industry, and values. They should also carefully review the job description to understand the specific responsibilities and qualifications required for the role.

- Visit the company’s website

- Review the job description thoroughly

2. Highlight Relevant Experience and Skills

Candidates should focus on highlighting their relevant experience and skills that align with the job requirements. They should provide specific examples of their work experience that demonstrate their abilities in combine operation, grain handling, and machine maintenance.

- Quantify your accomplishments and provide metrics

- Use the STAR method (Situation, Task, Action, Result)

3. Practice Common Interview Questions

Practicing common interview questions can help candidates build confidence and prepare for the actual interview. Some common questions include: “Why are you interested in this role?”, “Tell me about your experience in operating combine harvesters?”, and “How do you handle stressful situations in the field?”.

- Anticipate potential questions

- Prepare thoughtful and concise answers

4. Dress Professionally and Arrive on Time

Candidates should dress professionally for the interview and arrive on time to show respect for the interviewer and the company. This includes wearing clean and appropriate clothing and arriving at the interview location a few minutes early.

- Dress appropriately for the position

- Be punctual

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Grain Combiner role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.