Feeling lost in a sea of interview questions? Landed that dream interview for Grain Drier but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Grain Drier interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

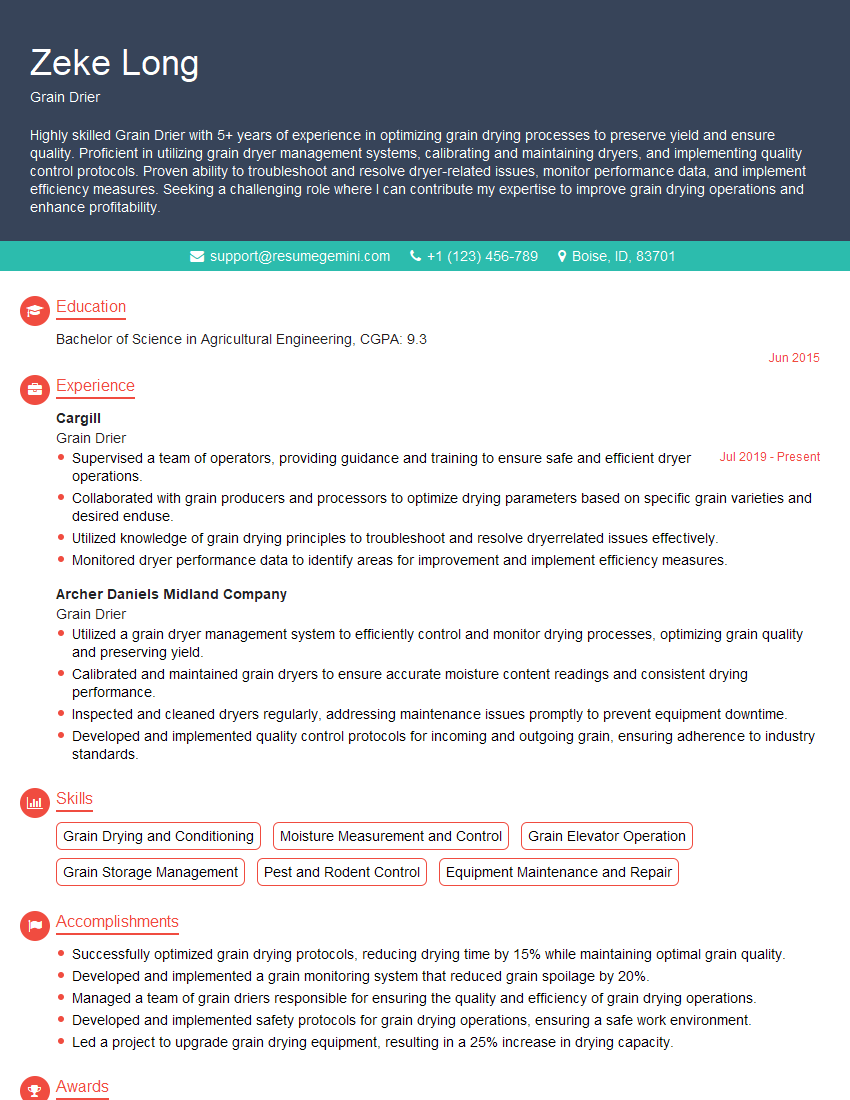

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Grain Drier

1. Describe the key principles of grain drying?

The key principles of grain drying involve removing excess moisture from the grain to prevent spoilage and ensure its quality. Grain drying typically involves the following steps:

- Assessing the initial moisture content of the grain

- Determining the desired moisture content based on storage conditions and end-use

- Selecting an appropriate drying method (e.g., natural air drying, heated air drying, etc.)

- Monitoring the drying process to ensure uniform moisture reduction and prevent over-drying

- Maintaining appropriate storage conditions to prevent moisture re-absorption

2. Explain the different types of grain driers and their applications?

Batch Dryers

- Used for small-scale drying operations

- Grain is loaded into a bin or container and heated air is circulated

Continuous-Flow Dryers

- Suitable for large-scale operations

- Grain is continuously fed into the dryer and moves through a drying zone

Tower Dryers

- Tall, vertical structures used for continuous drying

- Grain flows down through the tower while heated air moves upward

Other Types

- Pneumatic Dryers: Use heated air to convey and dry grain simultaneously

- Microwave Dryers: Utilize microwave energy to penetrate and dry grain kernels

3. How do you determine the optimum drying temperature and airflow rate for different grains?

To determine the optimum drying temperature and airflow rate for different grains, the following factors need to be considered:

- Grain type and moisture content

- Desired final moisture content

- Drying equipment capabilities

By considering these factors, the appropriate temperature and airflow rate can be selected to ensure efficient and effective grain drying while preserving grain quality.

4. Describe the importance of monitoring grain moisture content during the drying process?

Monitoring grain moisture content during the drying process is crucial for several reasons:

- Ensures uniform drying and prevents over-drying

- Helps maintain grain quality and minimize losses

- Prevents the growth of mold and bacteria

- Allows for adjustments to the drying process as needed

- Provides documentation of the drying process for quality control and traceability

5. What are the common problems encountered during grain drying and how do you address them?

Common problems encountered during grain drying include:

- Over-drying: Can result in reduced grain quality and increased breakage. Add moisture back to the grain or adjust drying parameters.

- Uneven drying: Can lead to moisture pockets and spoilage. Ensure proper airflow and adjust bin loading.

- Mold growth: High moisture content and inadequate drying can cause mold. Increase drying temperature and airflow, and monitor moisture levels.

- Insect infestation: Can occur if grain is not properly stored after drying. Implement pest control measures and maintain proper storage conditions.

6. How do you ensure the quality and safety of dried grain?

To ensure the quality and safety of dried grain, the following measures can be taken:

- Monitor moisture content and temperature throughout the drying process

- Inspect grain for any signs of damage, mold, or insect infestation

- Store grain in clean, dry, and well-ventilated areas

- Follow proper grain handling and storage practices

7. What is the role of automation in modern grain drying systems?

Automation in modern grain drying systems plays a significant role in improving efficiency, accuracy, and consistency:

- Automated moisture sensors monitor grain moisture content and adjust drying parameters accordingly

- Temperature and airflow controls regulate drying conditions to optimize grain quality

- Loading and unloading systems automate grain handling, reducing labor requirements

- Data logging and reporting features provide detailed records and insights into the drying process

8. How do you stay up-to-date with the latest advancements in grain drying technology?

To stay up-to-date with the latest advancements in grain drying technology, I regularly engage in the following activities:

- Attend industry conferences and workshops

- Read technical journals and research papers

- Network with other grain drying professionals

- Explore online resources and manufacturer websites

9. How do you handle unexpected breakdowns or maintenance issues during grain drying operations?

To handle unexpected breakdowns or maintenance issues during grain drying operations, I follow these steps:

- Assess the situation and identify the problem

- Isolate the affected equipment or area

- Consult technical manuals or contact the manufacturer for guidance

- Perform necessary repairs or maintenance

- Test the system to ensure functionality

10. Describe your experience in troubleshooting and resolving grain drying problems?

During my experience as a Grain Drier, I have encountered various grain drying problems and successfully resolved them. One notable instance was when:

- Problem: Uneven drying in a batch dryer

- Troubleshooting: Inspected the airflow system and identified a blocked duct. Adjusted the airflow distribution to ensure consistent drying

Another example:

- Problem: Over-drying in a continuous-flow dryer

- Troubleshooting: Monitored grain moisture content and adjusted the drying temperature and airflow rate. Implemented a feedback control system to maintain optimal drying conditions

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Grain Drier.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Grain Drier‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Grain Driers are responsible for operating and maintaining grain drying equipment to ensure the proper moisture content of grains.

1. Operating Grain Drying Equipment

This includes:

- Loading and unloading grain from dryers

- Monitoring and adjusting dryer settings, such as temperature, humidity, and airflow

- Ensuring that the drying process meets the required specifications

2. Maintaining Grain Drying Equipment

This includes:

- Performing regular inspections and maintenance on dryers

- Troubleshooting and repairing minor mechanical issues

- Lubricating and cleaning equipment as needed

3. Monitoring Grain Quality

This includes:

- Sampling and testing grain to determine its moisture content

- Assessing the quality of the dried grain and making adjustments to the drying process as needed

- Identifying and reporting any quality issues to supervisors

4. Safety and Compliance

This includes:

- Following all safety protocols and procedures

- Ensuring that the drying process meets all applicable regulations

- Maintaining a clean and organized work environment

Interview Tips

Preparing for an interview for a Grain Drier position can be daunting, but with the right preparation and mindset, you can increase your chances of making a great impression and landing the job.

1. Research the Role and Company

Before the interview, take the time to research the Grain Drier position and the company you’re applying to. This will help you understand the specific requirements of the role and tailor your answers to the interviewer’s questions.

- Review the job description thoroughly.

- Visit the company’s website to learn about their mission, values, and products/services.

2. Practice Common Interview Questions

There are a number of common interview questions that you’re likely to be asked in an interview for a Grain Drier position. By practicing these questions in advance, you can become more comfortable and confident in your answers.

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What is your experience in operating and maintaining grain drying equipment?

- How do you ensure that the drying process meets the required specifications?

3. Highlight Your Relevant Skills and Experience

During the interview, be sure to highlight your relevant skills and experience that make you a suitable candidate for the Grain Drier position.

- Emphasize your experience in operating and maintaining grain drying equipment.

- Describe your understanding of the grain drying process and the factors that affect grain quality.

- Share examples of how you have successfully resolved problems or improved efficiency in a previous role.

4. Prepare Questions to Ask

At the end of the interview, you will typically be given an opportunity to ask questions. This is a great time to show your interest in the position and the company and to gain additional insights into the role.

- What are the key challenges and opportunities facing the Grain Drier team?

- What are the company’s plans for growth in the future?

- What is the company’s culture like?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Grain Drier interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!