Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Grain Drier Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Grain Drier Operator so you can tailor your answers to impress potential employers.

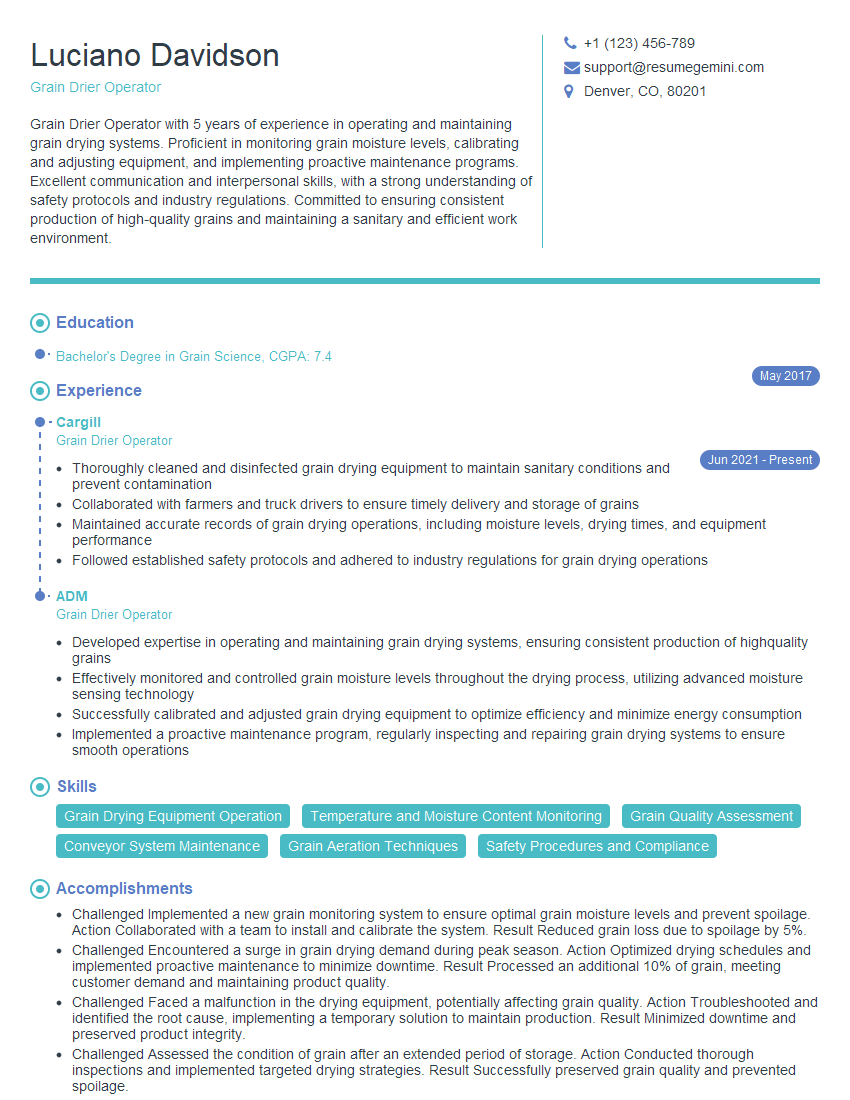

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Grain Drier Operator

1. How do you monitor the moisture content of the grain during the drying process, and what adjustments do you make based on the readings?

- Use a moisture meter to measure the moisture content of the grain.

- Adjust the drying temperature and airflow rate based on the moisture readings to achieve the desired moisture content.

2. What are the key factors that can affect the drying rate of grain, and how do you optimize the process for different types of grain?

Factors affecting drying rate:

- Moisture content of the grain

- Temperature

- Airflow rate

- Grain type

Optimization for different grain types:

- Adjust temperature and airflow rate based on grain type

- Monitor moisture content closely

- Consider using additives or pre-treatments to enhance drying

3. Describe the steps involved in maintaining and calibrating the grain drying equipment.

- Inspect and clean equipment regularly

- Calibrate temperature sensors and moisture meters

- Monitor and adjust airflow rates

- Lubricate and maintain moving parts

- Follow manufacturer’s maintenance schedule

4. How do you troubleshoot common problems that arise during the grain drying process, such as uneven drying or excessive energy consumption?

- Uneven drying: Check airflow distribution, temperature settings, and grain flow

- Excessive energy consumption: Optimize drying parameters, check equipment efficiency, and consider energy-efficient upgrades

5. What safety precautions must be taken when operating a grain drier, and how do you ensure the safety of yourself and others?

- Wear appropriate protective gear (mask, gloves, earplugs)

- Follow lockout/tagout procedures

- Be aware of potential hazards (dust explosions, grain entrapment)

- Maintain a clean and organized work area

- Receive regular safety training

6. How do you manage the grain drying process to meet customer specifications, minimize waste, and ensure product quality?

- Establish clear drying parameters based on customer requirements

- Monitor the drying process closely to prevent over- or under-drying

- Inspect the dried grain for quality and remove any damaged or contaminated kernels

- Follow good storage practices to maintain product quality

7. Describe your experience with different types of grain drying systems, and discuss the advantages and disadvantages of each.

- Batch dryers: Advantages – flexibility, smaller scale; Disadvantages – slower, less efficient

- Continuous dryers: Advantages – higher capacity, more efficient; Disadvantages – less flexible, higher initial cost

- Tower dryers: Advantages – high capacity, uniform drying; Disadvantages – expensive, requires specialized knowledge

8. How do you stay up-to-date with the latest advancements in grain drying technology, and how do you implement these advancements in your work?

- Attend industry conferences and workshops

- Read trade publications and research papers

- Network with other grain drying professionals

- Evaluate new technologies for potential implementation

9. What is your understanding of the environmental regulations related to grain drying, and how do you ensure compliance?

- Familiar with local, state, and federal environmental regulations

- Implement measures to minimize dust emissions and waste generation

- Use energy-efficient practices to reduce carbon footprint

10. How do you handle challenging situations or unexpected events that arise during the grain drying process?

- Remain calm and assess the situation

- Consult with colleagues or supervisors if necessary

- Take appropriate action to mitigate the issue

- Document the incident and implement corrective measures

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Grain Drier Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Grain Drier Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Grain Drier Operators play a crucial role in maintaining the quality of grains by operating and monitoring grain drying equipment to remove excess moisture content, thus preventing spoilage and preserving the grains’ properties.

1. Grain Drying Operation

Operate grain drying equipment such as dryers, conveyors, and elevators to remove moisture from the grains.

- Monitor and adjust temperature, airflow, and drying time to ensure optimal drying conditions.

- Inspect and maintain drying equipment to ensure proper functioning and safety.

2. Grain Quality Monitoring

Monitor the moisture content of grains using moisture meters or other testing methods.

- Record and maintain data on grain quality, including moisture content and temperature.

- Identify and segregate grains based on quality parameters to maintain uniformity.

3. Equipment Maintenance

Perform routine maintenance on grain drying equipment, including cleaning, lubrication, and repairs.

- Inspect equipment for wear and tear, and report any issues for timely resolution.

- Follow safety protocols and industry best practices to ensure safe operation and maintenance.

4. Grain Storage

Store dried grains in appropriate containers or silos to maintain quality and prevent spoilage.

- Monitor grain storage conditions, including temperature and humidity, to ensure optimal preservation.

- Control pests and rodents to prevent contamination and damage to stored grains.

Interview Tips

Preparing thoroughly for a Grain Drier Operator interview can significantly increase your chances of success. Here are some tips to help you ace the interview:

1. Research the Role and Company

Take the time to research the specific role and the company you’re applying to. Understand the company’s values, goals, and the industry in which they operate. This will demonstrate your interest and enthusiasm for the position.

- Visit the company website and read about their mission, products, and services.

- Look for news articles or industry reports about the company to gain insights into their recent developments and challenges.

2. Highlight Relevant Skills and Experience

Carefully review the job description and identify the key skills and experiences required for the role. Showcase your relevant skills and experience in your resume and during the interview.

- Emphasize your experience with grain drying equipment, moisture measurement techniques, and grain quality standards.

- Highlight your ability to work independently, monitor processes, and troubleshoot equipment issues.

3. Practice Common Interview Questions

Prepare for common interview questions related to your skills, experience, and motivation. Practice answering these questions out loud to gain confidence and clarity.

- Tell me about your experience in operating grain drying equipment.

- How do you ensure the quality of dried grains and maintain industry standards?

- Describe a time when you faced a challenge in grain drying and how you resolved it.

4. Ask Thoughtful Questions

Asking thoughtful questions during the interview demonstrates your interest and engagement. Prepare questions about the company’s grain drying practices, industry trends, or opportunities for professional development.

- What are the company’s sustainability initiatives related to grain drying?

- What are the latest advancements in grain drying technology that the company is considering?

- Are there opportunities for training or professional development within the company?

5. Dress Professionally and Arrive on Time

First impressions matter, so dress professionally and arrive on time for the interview. This shows respect for the interviewer and the company.

- Wear clean, pressed clothing appropriate for an industrial or agricultural setting.

- Be punctual and allow ample time for travel and unexpected delays.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Grain Drier Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Grain Drier Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.