Feeling lost in a sea of interview questions? Landed that dream interview for Grain Elevator Worker but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Grain Elevator Worker interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

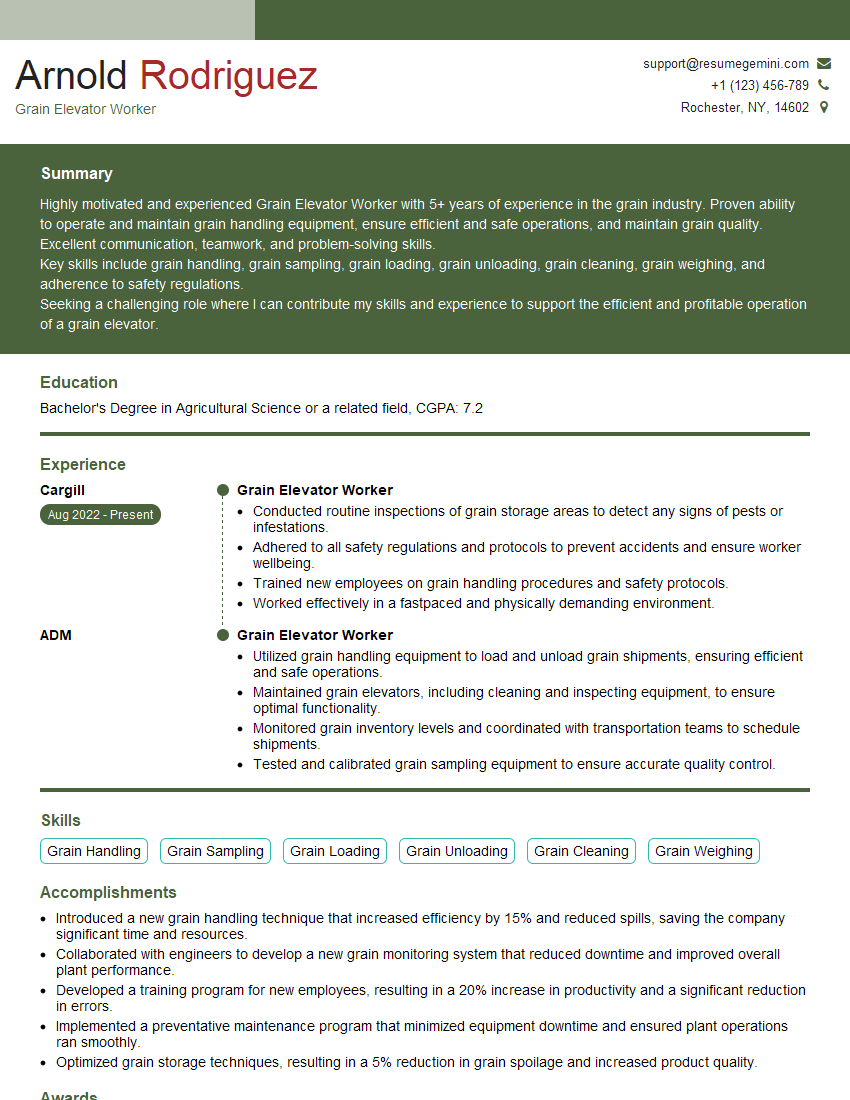

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Grain Elevator Worker

1. What are the different types of grain elevators and their uses?

- Flat storage elevators: Used for storing large quantities of grain in a single, flat-bottomed structure.

- Bin elevators: Consist of multiple vertical bins that are used to store different types or grades of grain.

- Country elevators: Located in rural areas and used to receive grain from farmers and prepare it for shipment.

- Terminal elevators: Located at ports or major transportation hubs and used to store and load grain onto ships or trains.

- Processing elevators: Equipped with machinery to clean, sort, and process grain before it is stored or shipped.

2. Describe the process of unloading grain from trucks into an elevator.

Safety Precautions

- Wear appropriate safety gear (e.g., hard hat, safety glasses).

- Inspect the truck and ensure it is stable before unloading.

- Identify the type of grain and ensure it is compatible with the elevator system.

Unloading Procedure

- Connect the unloading hose to the truck’s unloading port.

- Start the unloading process and monitor the flow of grain.

- Adjust the unloading rate as needed to prevent blockages or damage to equipment.

- Clean up any spilled grain after unloading is complete.

3. What are the key factors to consider when inspecting grain for quality?

- Visual inspection: Check for foreign objects, pests, or damage to kernels.

- Moisture content: Determine the percentage of moisture in the grain to ensure it is suitable for storage.

- Foreign material: Inspect for any non-grain materials, such as dirt, sticks, or weeds.

- Insect damage: Examine for signs of insect infestation, such as webbing or holes in kernels.

- Disease: Check for any visible symptoms of diseases that could affect the quality of the grain.

4. Describe the steps involved in sampling grain for analysis.

- Select a representative sample: Collect grain from different locations within the bin or load.

- Reduce the sample size: Divide the sample into smaller portions using a sample divider.

- Prepare the sample: Grind or prepare the sample according to laboratory requirements.

- Submit the sample for analysis: Send the prepared sample to a laboratory for testing.

5. What are the potential hazards associated with working in a grain elevator and how can they be minimized?

- Grain dust explosions: Minimize dust accumulation by regular cleaning and using dust collection systems.

- Grain bin entrapment: Implement safety measures such as bin entry permits and safety harnesses.

- Machinery hazards: Ensure proper guarding and maintenance of all machinery.

- Chemical hazards: Use chemicals safely and follow proper storage and disposal procedures.

- Fall hazards: Provide adequate fall protection for work areas and walkways.

6. Describe the maintenance procedures for grain handling equipment.

- Regular cleaning and lubrication: Clean and lubricate equipment according to manufacturer’s instructions.

- Inspections: Perform regular inspections for wear and tear, damage, and corrosion.

- Repairs and adjustments: Make necessary repairs and adjustments promptly to maintain equipment functionality.

- Calibration: Calibrate weighing and measuring equipment regularly for accuracy.

- Documentation: Keep detailed records of all maintenance activities and repairs performed.

7. What are the key responsibilities of a Grain Elevator Worker?

- Unload grain from trucks and rail cars.

- Inspect grain for quality and prepare it for storage.

- Operate grain handling equipment and conveyors.

- Maintain and repair grain handling equipment.

- Monitor grain storage conditions and prevent spoilage.

- Ensure compliance with safety regulations and protocols.

8. How do you handle situations where different types of grain need to be stored together?

- Isolate different types of grain: Store different types of grain in separate bins or compartments to prevent cross-contamination.

- Consider grain compatibility: Ensure that the different types of grain are compatible for storage, considering factors such as moisture content and potential for insect infestation.

- Monitor storage conditions: Regularly inspect the stored grain for signs of spoilage or insect activity.

9. Describe your experience in operating and maintaining grain handling equipment.

- Conveyor systems: Experience in operating and troubleshooting conveyor belts, screw augers, and grain legs.

- Grain cleaners: Knowledge of how to operate and maintain grain cleaners, such as separators and aspirators.

- Loaders and unloaders: Experience in using equipment to load and unload grain from trucks and rail cars.

- Grain dryers: Understanding of how to operate and maintain grain dryers, including temperature and airflow controls.

10. What is your understanding of the importance of safety in a grain elevator?

- Prevention of grain dust explosions: Recognize the dangers of grain dust and follow safety protocols to prevent ignition.

- Confined space safety: Understand the risks associated with working in confined spaces, such as grain bins, and follow proper entry procedures.

- Electrical safety: Ensure proper grounding of electrical equipment and follow lockout/tagout procedures when servicing.

- Personal protective equipment: Wear appropriate safety gear, including respirators, hard hats, and safety glasses.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Grain Elevator Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Grain Elevator Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

1. Operate and Maintain Grain Elevator Equipment

Grain Elevator Workers are responsible for the safe and efficient operation and maintenance of grain elevators. This includes:

- Monitoring and controlling the flow of grain through the elevator

- Maintaining and repairing equipment, such as conveyors, grain legs, and dust collectors

2. Inspect and Grade Grain

Grain Elevator Workers also inspect and grade grain as it is received and shipped. This involves:

- Checking the grain for quality, moisture content, and foreign material

- Grading the grain according to established standards

3. Load and Unload Grain

Grain Elevator Workers load and unload grain from trucks, rail cars, and barges. This involves:

- Using conveyors and other equipment to move grain

- Ensuring that grain is loaded and unloaded safely and efficiently

4. Clean and Sanitize Grain Elevator

Grain Elevator Workers are responsible for cleaning and sanitizing the grain elevator. This involves:

- Removing dust and grain from equipment and work areas

- Sanitizing the elevator to prevent the spread of pests and bacteria

Interview Tips

1. Research the Company and Position

Before you go on any interview, it is important to research the company and the position you are applying for. This will help you understand the company’s culture, values, and goals, as well as the specific requirements of the position.

- Visit the company’s website

- Read about the company in industry publications

- Talk to people who work for the company

2. Dress Professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the industry and position you are applying for.

- For men, this typically means a suit or dress pants and a button-down shirt.

- For women, this typically means a skirt or pantsuit.

3. Be Prepared to Answer Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as:

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

Practice answering these questions in advance so that you can deliver clear and concise responses.

4. Ask Questions

Asking questions at the end of an interview shows that you are interested in the position and the company. It also gives you an opportunity to learn more about the company and the position.

- What are the biggest challenges facing the company right now?

- What is the company’s culture like?

- What are the opportunities for advancement?

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Grain Elevator Worker role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.