Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Grain Thresher position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

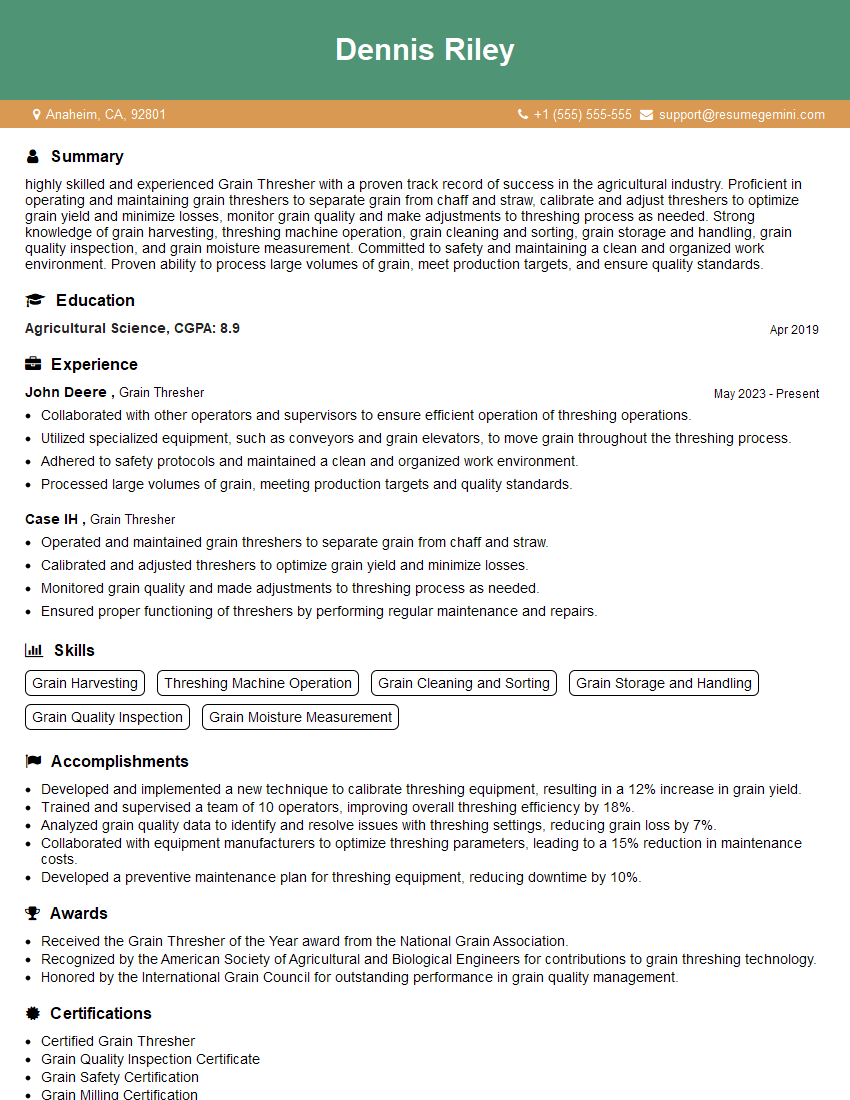

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Grain Thresher

1. What are the key components of a grain thresher and explain their functions?

A grain thresher is a machine used to separate the grain from the straw and chaff. The key components of a grain thresher include:

- Feeder: The feeder is responsible for feeding the grain into the thresher.

- Cylinder: The cylinder is a rotating drum with teeth that thresh the grain.

- Concave: The concave is a stationary surface with teeth that work with the cylinder to thresh the grain.

- Straw walker: The straw walker is a series of grates that separate the straw from the grain.

- Chaffer: The chaffer is a screen that separates the chaff from the grain.

- Grain pan: The grain pan is a container that collects the threshed grain.

2. What are the different types of grain threshers available in the market?

Axial-Flow Threshers

- Single rotor

- Double rotor

Conventional Threshers

- Hybrid threshers

- Rotary threshers

Other Threshers

- Spike-tooth threshers

- Rasp-bar threshers

3. What factors should be considered when selecting a grain thresher?

When selecting a grain thresher, the following factors should be considered:

- Capacity: The capacity of the thresher is determined by the size of the drum and the speed at which it rotates.

- Efficiency: The efficiency of the thresher is determined by the amount of grain that is separated from the straw and chaff.

- Durability: The durability of the thresher is determined by the quality of the materials used in its construction.

- Cost: The cost of the thresher is an important consideration.

4. What are the common problems that can occur with grain threshers?

The common problems that can occur with grain threshers include:

- Blockages: Blockages can occur in the feeder, cylinder, or straw walker.

- Breakages: Breakages can occur in the cylinder, concave, or straw walker.

- Wear and tear: Wear and tear can occur on the cylinder, concave, and straw walker.

- Improper adjustment: Improper adjustment can lead to problems with the threshing process.

5. What are the maintenance procedures that should be performed on a grain thresher?

The maintenance procedures that should be performed on a grain thresher include:

- Regular cleaning: The thresher should be cleaned after each use.

- Lubrication: The thresher should be lubricated according to the manufacturer’s instructions.

- Inspections: The thresher should be inspected regularly for signs of wear and tear.

- Repairs: Any necessary repairs should be performed promptly.

6. What are the safety precautions that should be taken when operating a grain thresher?

The safety precautions that should be taken when operating a grain thresher include:

- Wear appropriate clothing: Loose clothing and jewelry should not be worn.

- Keep hands and feet away from moving parts: Do not reach into the thresher while it is running.

- Do not operate the thresher in wet or slippery conditions: This could lead to accidents.

- Be aware of your surroundings: Make sure that there are no people or animals in the area before starting the thresher.

7. What are the environmental considerations that should be taken into account when using a grain thresher?

The environmental considerations that should be taken into account when using a grain thresher include:

- Noise pollution: Grain threshers can be noisy, so it is important to operate them in a way that minimizes noise pollution.

- Air pollution: Grain threshers can produce dust and other air pollutants, so it is important to operate them in a well-ventilated area.

- Water pollution: Grain threshers can generate wastewater, so it is important to dispose of it properly.

8. What are the emerging technologies that are being used in grain threshers?

The emerging technologies that are being used in grain threshers include:

- Laser sensors: Laser sensors can be used to detect and remove foreign objects from the grain.

- Computer vision: Computer vision can be used to identify and sort grain based on its size, shape, and color.

- Artificial intelligence: Artificial intelligence can be used to optimize the threshing process and improve the efficiency of the thresher.

9. What are the future trends in the grain threshing industry?

The future trends in the grain threshing industry include:

- Increased automation: Grain threshers are becoming increasingly automated, which is reducing the need for manual labor.

- Improved efficiency: Grain threshers are becoming more efficient, which is reducing the cost of grain production.

- Increased sustainability: Grain threshers are becoming more sustainable, which is reducing their environmental impact.

10. What are your strengths and weaknesses as a Grain Thresher?

Strengths:

- I have a strong understanding of the principles of grain threshing.

- I have experience operating and maintaining grain threshers.

- I am a hard worker and I am always willing to learn new things.

Weaknesses:

- I do not have experience operating the latest models of grain threshers.

- I am not familiar with all of the emerging technologies that are being used in grain threshers.

- I am not always the most efficient worker.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Grain Thresher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Grain Thresher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Grain Threshers are responsible for operating and maintaining grain threshing machines that separate grain from straw and chaff. Their key job responsibilities include:

1. Operating Grain Threshing Machines

Grain Threshers must be able to safely and efficiently operate grain threshing machines. This involves:

- Loading the machine with grain and adjusting settings to ensure optimal threshing performance.

- Monitoring the threshing process and making adjustments as needed to ensure proper separation of grain from straw and chaff.

- Unloading the threshed grain and straw into designated storage areas.

2. Maintaining and Repairing Grain Threshing Machines

Grain Threshers are also responsible for maintaining and repairing grain threshing machines. This involves:

- Performing routine maintenance tasks such as cleaning, lubricating, and inspecting the machine for any signs of wear or damage.

- Identifying and troubleshooting any mechanical or electrical problems that may arise during operation.

- Making minor repairs and adjustments to the machine as needed to ensure its proper functioning.

3. Ensuring Safety and Quality Control

Grain Threshers must always prioritize safety and quality control in their work. This involves:

- Following established safety protocols and wearing appropriate personal protective equipment (PPE) when operating and maintaining the machine.

- Inspecting the threshed grain for quality and ensuring that it meets the required standards.

- Taking steps to minimize grain loss and contamination during the threshing process.

4. Working in a Team Environment

Grain Threshers often work in a team environment with other agricultural workers. They must be able to:

- Effectively communicate with team members and supervisors to coordinate work activities.

- Collaborate with others to troubleshoot problems and ensure smooth operation of the threshing process.

- Contribute to a positive and productive work environment.

Interview Tips

To prepare for an interview for a Grain Thresher position, it is important to have a strong understanding of the key job responsibilities and to be able to demonstrate your skills and experience in these areas. Here are some tips to help you ace your interview:

1. Research the Company and Position

Before your interview, take the time to research the company and the specific Grain Thresher position you are applying for. This will help you better understand the company’s culture, values, and expectations for the role. You can find this information on the company’s website, social media pages, and other online resources.

2. Prepare for Common Interview Questions

There are certain interview questions that are commonly asked in Grain Thresher interviews. By preparing for these questions in advance, you can increase your chances of giving confident and articulate answers. Some common interview questions for Grain Threshers include:

- Tell me about your experience operating and maintaining grain threshing machines.

- What are some of the challenges you have faced in your previous role as a Grain Thresher, and how did you overcome them?

- How do you ensure safety and quality control in your work as a Grain Thresher?

- Why are you interested in working for our company?

- What are your strengths and weaknesses as a Grain Thresher?

3. Practice Your Answers

Once you have prepared for common interview questions, practice your answers out loud. This will help you become more comfortable speaking about your skills and experience, and it will also help you identify any areas where you need to improve your answers.

4. Be Enthusiastic and Professional

During your interview, it is important to be enthusiastic about the position and the company. This will show the interviewer that you are genuinely interested in the job and that you are confident in your abilities. However, it is also important to be professional and respectful throughout the interview process.

5. Ask Questions

At the end of your interview, be sure to ask the interviewer any questions that you may have about the position or the company. This shows that you are engaged and interested in the opportunity, and it also gives you a chance to clarify any information that you may have missed during the interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Grain Thresher interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!