Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Graining Press Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Graining Press Operator so you can tailor your answers to impress potential employers.

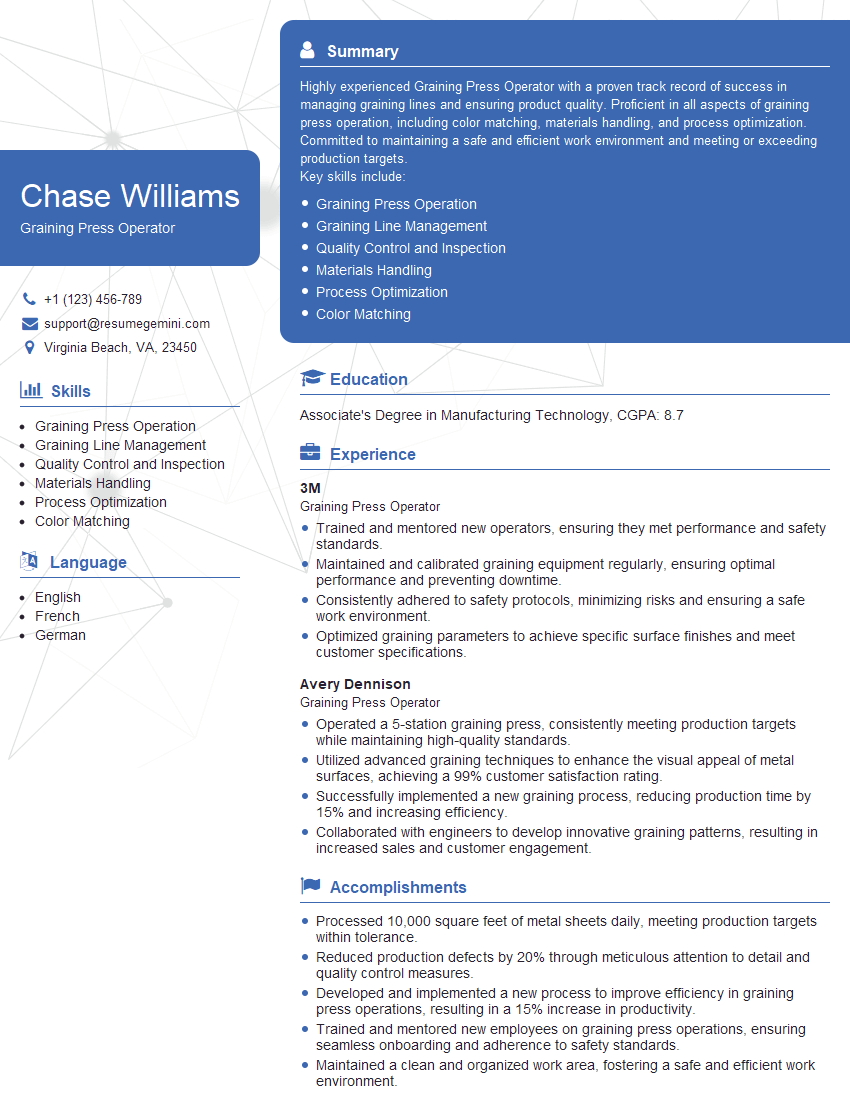

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Graining Press Operator

1. What are the main responsibilities of a Graining Press Operator?

The main responsibilities of a Graining Press Operator include:

- Operating and maintaining a graining press

- Preparing and loading material into the press

- Setting up and adjusting the press according to specifications

- Monitoring the press during operation and making adjustments as necessary

- Unloading the finished product from the press

- Performing quality control checks on the finished product

- Maintaining a clean and safe work area

2. What are the different types of graining presses?

- Roller graining press

- Flatbed graining press

- Rotary graining press

Each type of press has its own advantages and disadvantages, and the best type of press for a particular application will depend on the specific requirements of the job.

3. What are the key factors to consider when setting up a graining press?

When setting up a graining press, it is important to consider the following factors:

- The type of material being grained

- The desired grain pattern

- The thickness of the material

- The speed of the press

- The pressure of the press

All of these factors will affect the quality of the finished product.

4. What are the common defects that can occur in graining?

- Uneven grain pattern

- Scratches on the surface of the material

- Dents or gouges in the material

- Cracking or chipping of the material

- Delamination of the material

It is important to be able to identify these defects and to take steps to prevent them from occurring.

5. What are the safety precautions that must be followed when operating a graining press?

- Always wear appropriate safety gear, including gloves, safety glasses, and a dust mask.

- Never put your hands or any other body parts into the press while it is in operation.

- Keep the work area clean and free of debris.

- Never operate the press if it is not in good working order.

- Follow all manufacturer’s instructions for safe operation of the press.

By following these precautions, you can help to prevent accidents and injuries.

6. What are the maintenance procedures that should be followed for a graining press?

- Regularly clean the press and its components.

- Inspect the press for any damage or wear and tear.

- Lubricate the press according to the manufacturer’s instructions.

- Calibrate the press regularly to ensure that it is operating within specifications.

- Keep a maintenance log to track all maintenance activities.

By following these procedures, you can help to keep your press in good working condition and extend its lifespan.

7. What are the troubleshooting procedures that you would follow if the graining press is not operating properly?

- First, try to identify the problem by observing the press and its components.

- Then, consult the manufacturer’s instructions for troubleshooting.

- If you are unable to solve the problem yourself, contact a qualified technician.

By following these procedures, you can help to minimize downtime and keep your press running smoothly.

8. What are the different types of materials that can be grained?

- Wood

- Metal

- Plastic

- Glass

- Leather

The type of material will affect the settings that you need to use on the press.

9. What are the different types of grain patterns that can be created?

- Straight grain

- Cross grain

- Diagonal grain

- Herringbone grain

- Burlap grain

The type of grain pattern will affect the appearance of the finished product.

10. What are the quality standards for grained products?

- The grain pattern should be even and consistent.

- The surface of the material should be free of scratches or other defects.

- The material should be the correct thickness and density.

- The product should meet the customer’s specifications.

It is important to adhere to these quality standards to ensure that you are producing high-quality products.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Graining Press Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Graining Press Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Graining Press Operators play a crucial role in the production of wood-based products. They operate graining presses to apply decorative patterns to wood surfaces, simulating the appearance of natural wood grains. Their responsibilities encompass the following key areas:

1. Graining Press Operation

• Setting up and operating graining presses.

• Maintaining optimal pressure and temperature settings to ensure proper graining.

- Troubleshooting and resolving any issues with the graining press.

- Inspecting grained wood surfaces for defects and making necessary adjustments.

2. Material Handling

• Loading and unloading wood panels into and out of the graining press.

- Verifying the correct alignment and placement of wood panels.

- Maintaining a clean and organized work area.

3. Quality Control

• Monitoring the graining process to ensure quality standards are met.

- Identifying and correcting any deviations from established specifications.

- Communicating any quality concerns to supervisors.

4. Machine Maintenance

• Cleaning and lubricating graining presses as per maintenance schedules.

- Performing minor repairs and adjustments to ensure optimal press performance.

- Reporting any significant maintenance issues to supervisors.

Interview Preparation Tips

Thorough preparation is key to acing any job interview. Here are some valuable tips for candidates seeking to make a strong impression during their Graining Press Operator interview:

1. Research the Company and Position

• Gather information about the company’s history, products, and industry standing.

- Carefully review the job description to understand the specific responsibilities, skills, and qualifications required.

- Identify any areas where your experience and expertise align with the role.

2. Practice Common Interview Questions

• Prepare for questions related to your experience, skills, and knowledge of the graining press operation process.

- Consider using the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples of your abilities.

- Practice articulating your strengths and weaknesses, emphasizing your suitability for the role.

3. Research the Industry

• Stay up-to-date with industry trends and advancements in graining press technology.

- Read industry publications, attend webinars, and connect with professionals in the field.

- Demonstrate your eagerness to learn and contribute to the evolving industry landscape.

4. Dress Professionally and Arrive Punctually

• First impressions matter. Dress appropriately and arrive on time for your interview.

- Maintain a professional demeanor throughout the interview, showing respect for the interviewer and the company.

- Be enthusiastic and engaged, asking thoughtful questions that demonstrate your genuine interest in the role and the organization.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Graining Press Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.