Are you gearing up for a career in Granite Polisher? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Granite Polisher and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

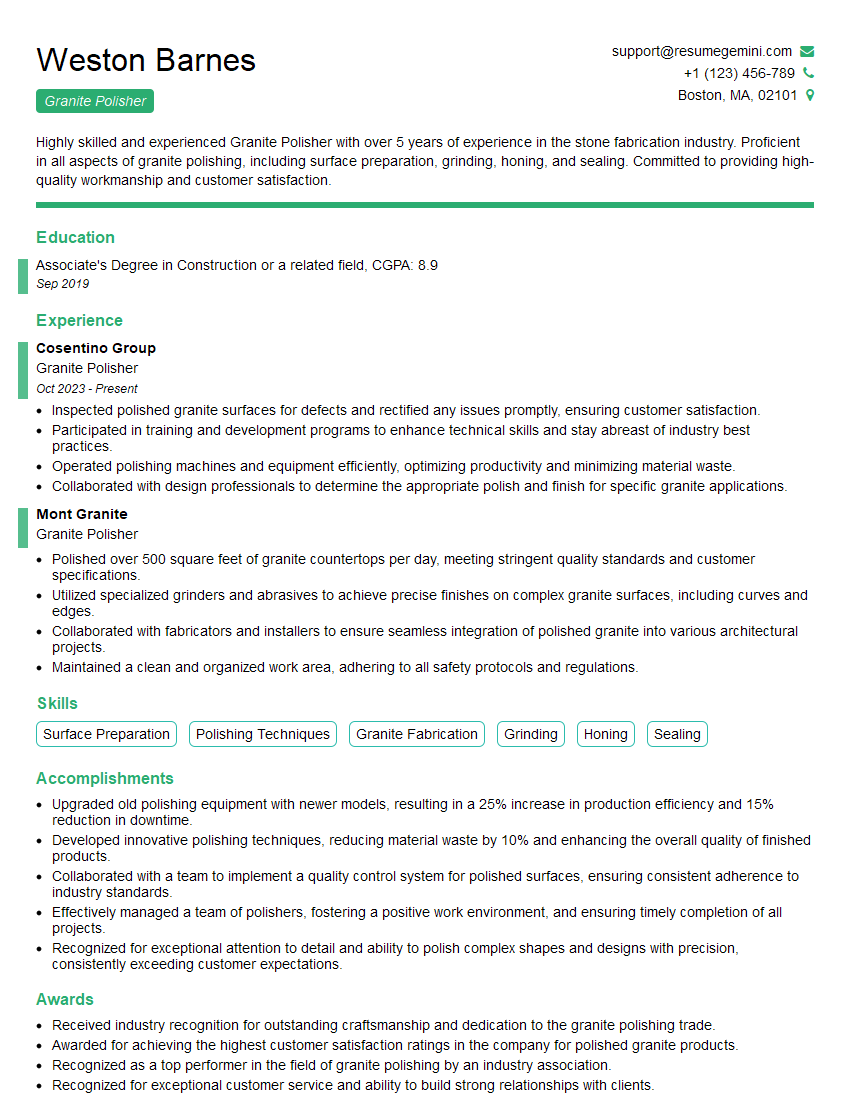

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Granite Polisher

1. Can you describe your step-by-step process for polishing granite?

- Prepare the surface by cleaning and removing any debris or dirt.

- Apply a rough grit diamond or silicon carbide grinding pad to a handheld or floor-mounted grinder to remove any imperfections or scratches on the surface.

- Gradually move to finer grit pads, such as 100 to 200 grit, 400 to 600 grit, and 800 to 1000 grit, to smooth out the surface.

- Use a 1200 to 1500 grit pad to further refine the surface, creating a high-gloss finish.

- Apply a sealant or wax to protect the polished surface.

2. What are the different types of granite polishing machines and their uses?

Handheld grinders

- Portable and easy to maneuver

- Typically used for small areas or detailed work

Floor-mounted grinders

- More powerful and stable

- Suitable for large-scale projects, such as floors and countertops

Wet grinders

- Use water to reduce dust and heat during the polishing process

- Produce a cleaner finish

3. What safety precautions should be taken when polishing granite?

- Wear protective gear, including gloves, goggles, and a dust mask.

- Ensure adequate ventilation to avoid inhaling dust particles.

- Use sharp and undamaged grinding pads to prevent accidents.

- Store and handle chemicals, such as sealants and cleaners, according to the manufacturer’s instructions.

4. How do you handle repairs or scratches on polished granite surfaces?

- Assess the severity of the damage and determine the appropriate repair method.

- If the scratch is minor, use a fine-grit diamond or cerium oxide pad to gently buff out the surface.

- For deeper scratches or chips, use a coarse-grit pad to remove excess material and then gradually switch to finer pads to smooth out the surface.

5. What are the latest advancements in granite polishing techniques?

- Laser polishing: Uses a laser to create a smooth and precise finish, reducing the need for traditional grinding.

- Waterjet polishing: Employs a high-pressure water jet to polish granite surfaces, minimizing dust and enhancing clarity.

- Nanotechnology polishing agents: Utilize nanoparticles to create a durable and scratch-resistant finish.

6. How do you determine the appropriate pressure and speed for polishing different types of granite?

- Consider the hardness and density of the granite.

- Use a slower speed and lighter pressure for softer granite to prevent gouging.

- Increase speed and pressure gradually for harder granite to achieve the desired finish.

7. What are the common challenges encountered during granite polishing and how do you overcome them?

- Uneven surface: Use a leveler to create a flat surface before polishing.

- Deep scratches: Repair deep scratches manually using fine-grit pads and a slow, steady motion.

- Dust and debris: Minimize dust by using wet grinders or attaching dust extractors to handheld machines.

8. How do you ensure consistency and quality in your granite polishing work?

- Follow a standardized polishing process that outlines specific steps and materials.

- Use high-quality polishing equipment and abrasives.

- Inspect surfaces regularly throughout the process to identify and correct any imperfections.

9. What is the difference between honing and polishing granite?

- Honing: Creates a matte or satin finish by removing surface imperfections and leaving a smooth, non-reflective texture.

- Polishing: Produces a high-gloss finish by using finer abrasives to create a reflective surface.

10. How do you stay up-to-date with the latest granite polishing trends and best practices?

- Attend industry events and conferences.

- Read trade publications and technical articles.

- Connect with other granite professionals and exchange knowledge.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Granite Polisher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Granite Polisher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

1. Surface Preparation

Granite polishers prepare the granite surface for polishing by cleaning, leveling, and filling any imperfections. This may involve using a variety of tools and techniques, such as grinders, sanders, and fillers.

2. Polishing

Once the surface is prepared, the granite polisher uses a polishing machine to create a smooth, glossy finish. This process can be done by hand or with a machine, and requires a high level of skill and precision.

3. Sealing

After the granite is polished, it is sealed to protect it from stains and damage. The polisher will apply a sealant to the surface, which will help to keep it looking its best for years to come.

4. Maintenance

Granite polishers may also be responsible for maintaining the appearance of the granite over time. This may involve cleaning, polishing, and resealing the surface as needed.

Interview Tips

Granite polishing is a specialized trade that requires a high level of skill and experience. When interviewing for a granite polishing job, it is important to highlight your skills and experience in the following areas:

1. Surface Preparation

Emphasize your experience in preparing granite surfaces for polishing. This may include using a variety of tools and techniques, such as grinders, sanders, and fillers.

2. Polishing

Describe your experience in polishing granite surfaces to a high level of shine. Explain the techniques you use to achieve a smooth, glossy finish.

3. Sealing

Explain your experience in sealing granite surfaces to protect them from stains and damage. Discuss the different types of sealants you have used and the benefits of each.

4. Maintenance

Highlight your experience in maintaining the appearance of granite surfaces over time. This may include cleaning, polishing, and resealing the surface as needed.

Next Step:

Now that you’re armed with the knowledge of Granite Polisher interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Granite Polisher positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini