Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Granulating Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

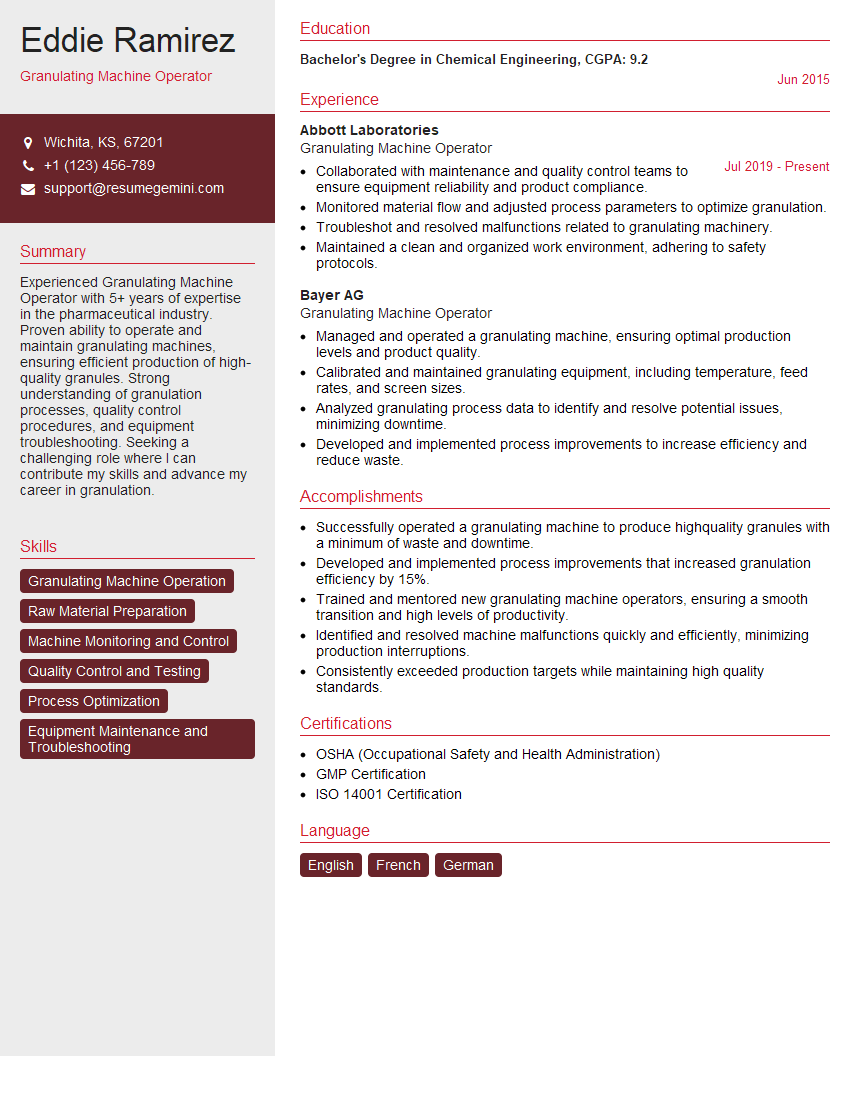

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Granulating Machine Operator

1. What is the principle of granulation?

Granulation is a process of forming small, round particles from a powder or liquid. In the granulating machine, the powder or liquid is fed into a rotating drum. The drum has a series of baffles or pins that cause the powder or liquid to break up into small particles. The particles are then carried away by a stream of air and deposited in a collection chamber.

2. What are the different types of granulating machines?

- Fluidized Bed Granulators: These machines use a stream of air to suspend the powder particles in a fluidized bed. The liquid binder is then sprayed onto the particles, which causes them to agglomerate into granules.

- High-Shear Granulators: These machines use a high-shear impeller to mix the powder and liquid binder together. The high shear forces cause the particles to break up and form granules.

- Roller Compaction Granulators: These machines use a pair of rollers to compact the powder into a sheet. The sheet is then broken up into granules by a series of knives.

3. What are the key factors that affect the granulation process?

- Particle size: The size of the powder particles affects the rate of granulation. Smaller particles granulate more quickly than larger particles.

- Liquid binder: The type and amount of liquid binder used affects the strength and porosity of the granules.

- Granulation speed: The speed of the granulating machine affects the size and shape of the granules.

- Temperature: The temperature of the granulating process can affect the rate of granulation and the properties of the granules.

4. What are the common problems associated with granulation?

- Overgranulation: This occurs when the granules are too large or too hard. Overgranulation can lead to problems with flowability and dissolution.

- Undergranulation: This occurs when the granules are too small or too weak. Undergranulation can lead to problems with segregation and dustiness.

- Capping: This occurs when the granules have a hard outer shell and a soft inner core. Capping can lead to problems with dissolution and bioavailability.

- Friability: This occurs when the granules are too fragile and break easily. Friability can lead to problems with handling and storage.

5. How do you troubleshoot common granulation problems?

- Overgranulation: Reduce the granulation speed, increase the amount of liquid binder, or use a different type of binder.

- Undergranulation: Increase the granulation speed, reduce the amount of liquid binder, or use a different type of binder.

- Capping: Increase the amount of liquid binder, reduce the granulation speed, or use a different type of binder.

- Friability: Increase the amount of liquid binder, reduce the granulation speed, or use a different type of binder.

6. What are the safety precautions that should be taken when operating a granulating machine?

- Wear appropriate personal protective equipment (PPE), such as safety glasses, gloves, and a lab coat.

- Do not operate the machine if you are not properly trained.

- Keep the work area clean and free of tripping hazards.

- Follow all manufacturer’s instructions for operation and maintenance.

7. What are your responsibilities as a Granulating Machine Operator?

- Operate the granulating machine according to manufacturer’s instructions.

- Monitor the granulation process and make adjustments as needed.

- Troubleshoot and resolve common granulation problems.

- Clean and maintain the granulating machine.

- Follow all safety procedures.

8. What are your strengths and weaknesses as a Granulating Machine Operator?

- Strengths: I am a highly skilled and experienced Granulating Machine Operator with a strong understanding of the granulation process. I am also a quick learner and am always willing to take on new challenges.

- Weaknesses: I am sometimes too focused on the details and can be slow to make decisions. I am also not always comfortable working with new people.

9. Why are you interested in this position?

I am interested in this position because I am passionate about granulation and I am confident that I have the skills and experience necessary to be successful in this role. I am also excited about the opportunity to contribute to your company’s success.

10. What are your salary expectations?

My salary expectations are commensurate with my experience and qualifications. I am confident that I can bring value to your company and I am willing to negotiate a salary that is fair to both of us.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Granulating Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Granulating Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Granulating Machine Operators are responsible for the operation, maintenance, and repair of granulating machines used in the production of pharmaceuticals, chemicals, and other products. Their key job responsibilities include:

1. Machine Operation

Operate granulating machines to produce granules of the desired size, shape, and consistency.

- Set up and adjust machine parameters, including granulator speed, temperature, and feed rate.

- Monitor machine performance and make adjustments as needed to ensure consistent product quality.

2. Maintenance and Repair

Perform routine maintenance and repairs on granulating machines to ensure optimal performance.

- Inspect and clean machines regularly to prevent breakdowns.

- Identify and troubleshoot malfunctions, and perform necessary repairs or adjustments.

3. Quality Control

Monitor the quality of granulated products and ensure they meet specifications.

- Collect and analyze samples to assess product quality.

- Adjust machine parameters or make process modifications to correct any quality deviations.

4. Safety and Compliance

Adhere to all safety regulations and protocols while operating and maintaining granulating machines.

- Wear appropriate personal protective equipment (PPE) at all times.

- Follow established lockout/tagout procedures to prevent accidents.

Interview Tips

To ace an interview for a Granulating Machine Operator position, it’s crucial to prepare thoroughly and showcase your skills and experience. Here are some tips to help you:

1. Research the Company and Position

Learn as much as possible about the company you’re applying to and the specific role you’re seeking. This will help you understand their business, culture, and the requirements of the job.

- Visit the company’s website and LinkedIn page.

- Read industry publications and news articles to stay informed about the latest trends in granulating technology.

2. Highlight Your Relevant Skills and Experience

In your resume and during the interview, emphasize your skills and experience that are directly relevant to the job responsibilities. This may include:

- Experience operating and maintaining granulating machines.

- Knowledge of granulation processes and quality control techniques.

- Understanding of safety protocols and regulatory compliance.

3. Practice Answering Common Interview Questions

Prepare answers to common interview questions, such as:

- “Tell me about your experience operating granulating machines.”

- “Describe how you ensure the quality of granulated products.”

- “What are some common safety hazards associated with operating granulating machines?”

4. Ask Insightful Questions

During the interview, ask thoughtful questions that demonstrate your interest in the position and the company. This can show that you’re engaged and eager to learn more.

- Ask about the company’s plans for future growth and investment in granulating technology.

- Inquire about the training and development opportunities available for Granulating Machine Operators.

- Ask about the company’s commitment to safety and environmental compliance.

Next Step:

Now that you’re armed with the knowledge of Granulating Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Granulating Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini