Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Gravel Inspector position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

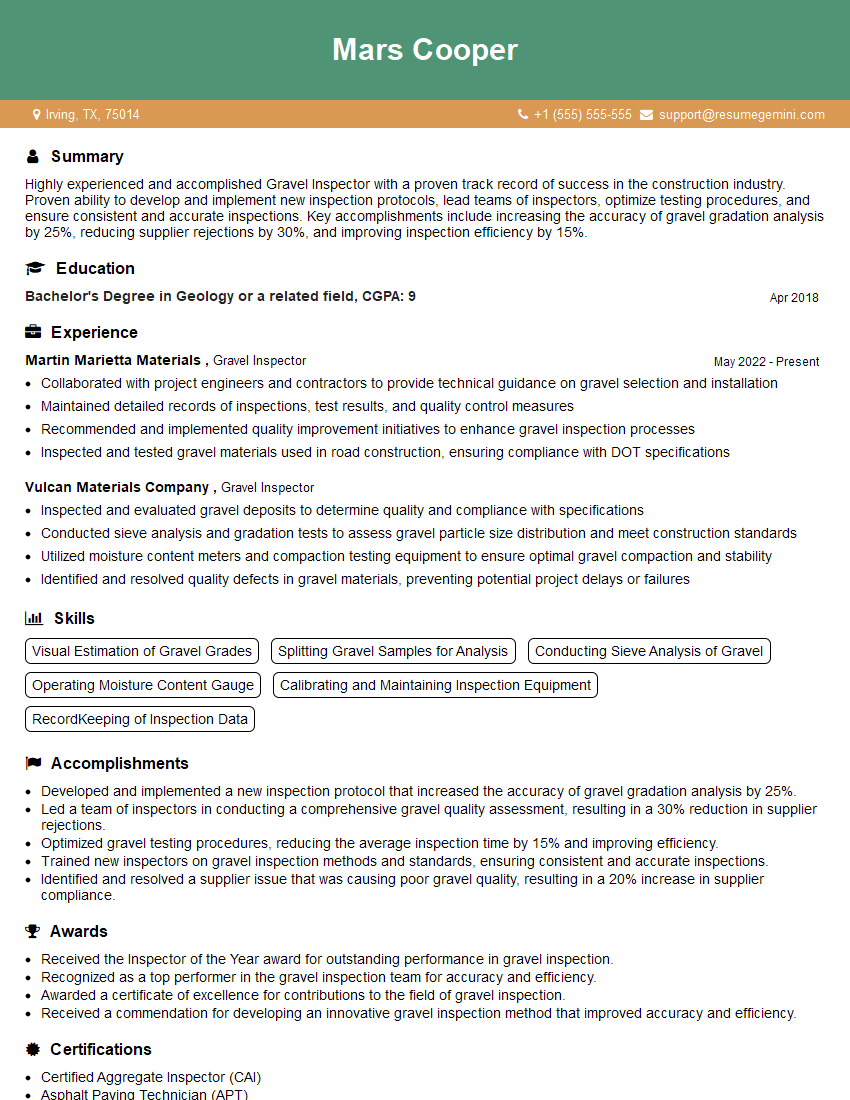

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Gravel Inspector

1. What are the key responsibilities of a gravel inspector?

As a gravel inspector, my primary responsibilities would encompass:

- Inspecting gravel aggregates to ensure compliance with established quality standards and specifications.

- Analyzing gravel samples through visual inspections and laboratory testing to determine physical characteristics such as gradation, shape, and durability.

2. How do you determine the gradation of gravel aggregates?

Sieve Analysis

- Utilizing a series of sieves with varying mesh sizes, I pass the gravel sample through each sieve to separate it into different size fractions.

- By weighing the retained material on each sieve, I calculate the percentage of gravel particles within each size range.

Hydrometer Analysis

- For finer gravel particles, I employ a hydrometer to measure their specific gravity and particle size distribution.

- This method involves dispersing the gravel sample in water and using a hydrometer to determine the density of the suspension over time.

3. What methods do you use to assess the shape and durability of gravel aggregates?

To evaluate the shape and durability of gravel aggregates, I employ the following methods:

- Visual Inspection: I examine the gravel particles under magnification to assess their angularity, roundness, and surface texture.

- Flakiness and Elongation Index Tests: These tests involve measuring the thickness and length of gravel particles to determine their flakiness and elongation characteristics.

- Los Angeles Abrasion Test: I subject the gravel sample to a tumbling drum with steel balls to assess its resistance to abrasion and impact.

4. How do you ensure the quality of gravel aggregates for different applications?

To ensure the quality of gravel aggregates for various applications, I adhere to the following process:

- Reviewing Specifications: I thoroughly examine project specifications to understand the required properties and performance criteria for the gravel.

- Testing and Analysis: I perform a comprehensive range of tests on gravel samples to determine their gradation, shape, durability, and other relevant characteristics.

- Compliance Verification: I compare the test results against the established specifications to ascertain whether the gravel meets the required standards.

- Documentation and Reporting: I meticulously document my findings and provide detailed reports outlining the test results and any recommendations for appropriate usage.

5. What are the most common defects or non-conformities you encounter during gravel inspections?

During gravel inspections, I frequently encounter the following defects or non-conformities:

- Gradation Issues: Gravel may not meet the specified gradation requirements, resulting in an imbalance of particle sizes.

- Shape and Durability Concerns: Gravel may exhibit excessive flakiness or elongation, or insufficient durability to withstand the intended application.

- Contamination: Gravel may contain impurities such as clay, silt, or organic matter, which can affect its performance.

- Moisture Content: Gravel may have excessive moisture content, making it unsuitable for certain applications.

6. How do you handle situations where gravel does not meet the required specifications?

When gravel does not meet the required specifications, I take the following steps:

- Notification: I promptly inform the supplier or contractor of the non-conformity and provide them with the test results.

- Investigation: I conduct a thorough investigation to determine the cause of the non-conformity and identify any potential corrective actions.

- Recommendations: I provide recommendations for rectifying the issue, such as re-screening or blending the gravel to meet the specifications.

- Re-testing: Once corrective measures have been implemented, I perform re-testing to verify that the gravel now complies with the requirements.

7. What are the latest industry standards and best practices related to gravel inspection?

To stay abreast of the latest industry standards and best practices, I actively engage in the following:

- Professional Development: I attend industry conferences, workshops, and training programs to enhance my knowledge and skills.

- Membership in Professional Organizations: I maintain memberships in professional organizations such as ASTM International and the National Asphalt Pavement Association (NAPA) to stay informed about industry advancements.

- Review of Technical Literature: I regularly review technical journals, research papers, and industry publications to keep up with the latest developments.

8. How do you ensure the accuracy and reliability of your inspection results?

I adhere to the following principles to ensure the accuracy and reliability of my inspection results:

- Calibration and Maintenance: I regularly calibrate and maintain all testing equipment according to manufacturer’s specifications.

- Standardized Procedures: I follow standardized testing procedures and protocols to minimize variability and ensure consistent results.

- Quality Control: I implement a quality control system to monitor the accuracy and precision of my testing methods.

- Independent Verification: When necessary, I seek independent verification of my results through third-party testing laboratories.

9. How do you communicate your inspection findings and recommendations effectively?

To effectively communicate my inspection findings and recommendations, I employ the following strategies:

- Clear and Concise Reports: I prepare comprehensive inspection reports that clearly outline my findings, conclusions, and recommendations.

- Verbal Presentations: I present my findings verbally to clients, engineers, and contractors, using visual aids and supporting documentation to enhance understanding.

- Collaboration and Discussion: I actively engage in discussions and collaborate with stakeholders to ensure that my recommendations are well-received and understood.

10. What sets you apart as an exceptional gravel inspector?

My exceptional qualities as a gravel inspector include:

- Technical Expertise: I possess a strong foundation in materials science, testing methodologies, and industry standards.

- Attention to Detail: I am meticulous in my inspections, ensuring that no aspect of the gravel is overlooked.

- Problem-Solving Skills: I am adept at identifying and resolving non-conformities to ensure the delivery of high-quality gravel.

- Communication and Interpersonal Skills: I effectively communicate my findings and recommendations to stakeholders at all levels.

- Commitment to Quality: I am passionate about ensuring the quality of gravel used in construction projects, contributing to safety and durability.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Gravel Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Gravel Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Gravel Inspectors are responsible for ensuring that gravel meets the specifications set by the company. They inspect gravel for size, shape, and quality. They also test the gravel for strength and durability. Gravel Inspectors work in a variety of settings, including quarries, mines, and construction sites.

1. Inspect gravel for size, shape, and quality

Gravel Inspectors use a variety of tools to inspect gravel. They use sieves to determine the size of the gravel. They use calipers to measure the shape of the gravel. They also use visual inspection to check for the quality of the gravel.

- Determine the size and shape of gravel particles using sieves and calipers.

- Examine gravel for impurities, defects, and other factors affecting quality.

2. Test gravel for strength and durability

Gravel Inspectors use a variety of tests to determine the strength and durability of gravel. They use the Los Angeles Abrasion Test to measure the resistance of gravel to wear and tear. They also use the Micro-Deval Abrasion Test to measure the resistance of gravel to polishing.

- Conduct tests to assess the strength and durability of gravel, such as the Los Angeles Abrasion Test and Micro-Deval Abrasion Test.

- Analyze test results to determine whether gravel meets specifications.

3. Report findings and recommendations

Gravel Inspectors report their findings and recommendations to their supervisors. They may also write reports for clients. Gravel Inspectors may also make recommendations on how to improve the quality of gravel.

- Document inspection findings and test results in reports.

- Communicate findings and recommendations to supervisors and clients.

4. Maintain equipment and tools

Gravel Inspectors are responsible for maintaining their equipment and tools. They may also be responsible for calibrating their equipment.

- Maintain and calibrate inspection equipment and tools.

- Ensure equipment is in proper working order to ensure accurate inspections.

Interview Tips

Preparing for a Gravel Inspector interview can be daunting, but there are certain tips and tricks that can help you ace the interview and land the job.

1. Research the company and the position

Before you go to the interview, it is important to do your research on the company and the position. This will help you understand the company’s culture and the specific requirements of the job.

- Visit the company’s website to learn about their history, mission, and values.

- Read job descriptions carefully and identify the key skills and qualifications required.

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked. It is important to practice your answers to these questions so that you can deliver them confidently and concisely.

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

3. Be prepared to talk about your experience

The interviewer will likely want to know about your experience in the field. Be prepared to talk about your previous jobs and how they have prepared you for this position.

- Highlight your experience in inspecting gravel, conducting tests, and reporting findings.

- Quantify your accomplishments whenever possible, using specific numbers and metrics.

4. Be enthusiastic and positive

The interviewer will be looking for someone who is enthusiastic and passionate about the job. Be sure to convey your interest in the position and your willingness to work hard.

- Demonstrate your passion for the industry and your commitment to quality.

- Be positive and enthusiastic throughout the interview, even if you are nervous.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Gravel Inspector role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.