Are you gearing up for an interview for a Gravel Screener position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Gravel Screener and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

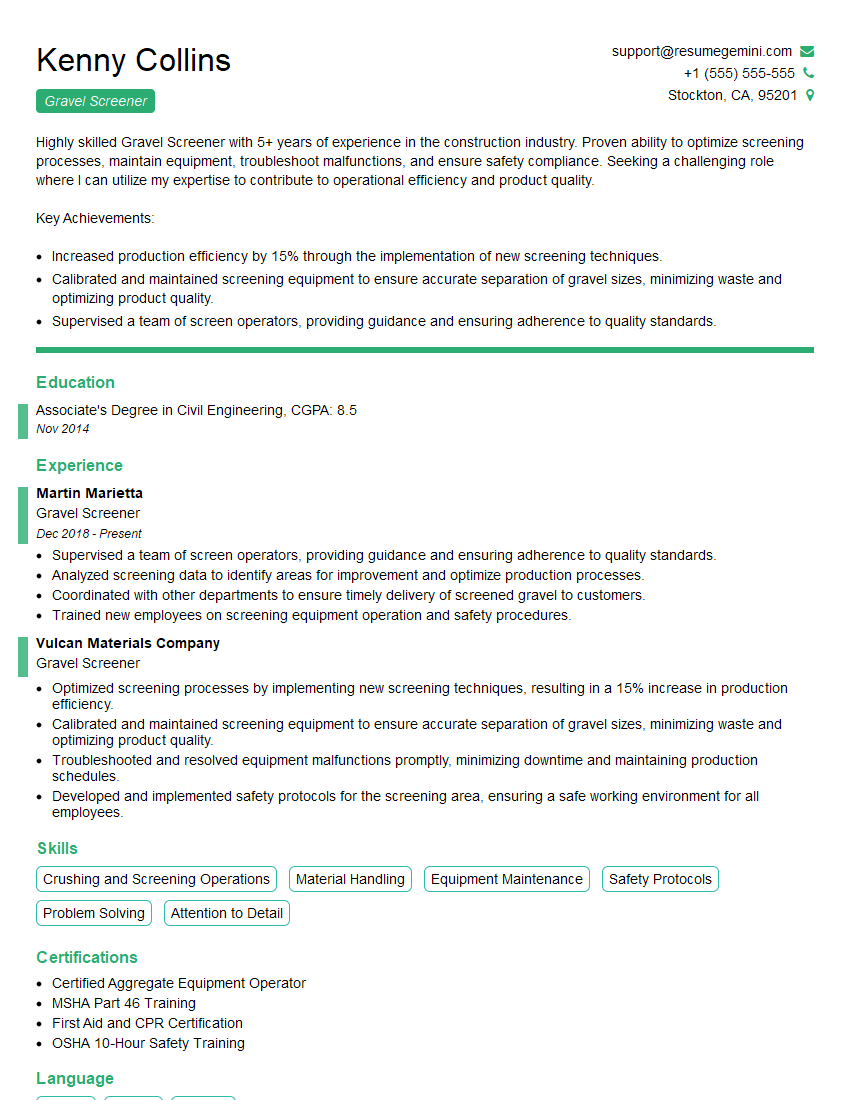

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Gravel Screener

1. What are the different types of gravel screens used in the industry?

- Fixed Bar Screens

- Vibrating Screens

- Rotary Screens

- Trommel Screens

2. What are the key factors to consider when selecting a gravel screen?

Machine Capacity

- Gravel screening machines have different capacities. Capacities typically range from 10 to 1000 TPH depending on the equipment used.

Gravel Type

- There are different types of gravel but they can be classified into rounded and angular gravel. Screening equipment must be chosen based on the type of gravel that is being processed.

Screening Efficiency

- Screening efficiency refers to the quantity of particles that must be recycled versus the quantity of acceptable screened product. For instance if the screening machine has 85 percent screening efficiency, 15 percent of the particles must be recycled.

Durability

- Screening machines must be designed using materials that can withstand abrasive materials and harsh weather conditions.

3. How do you set up and operate a gravel screening plant?

- Preparation and planning.

- Installing the necessary equipment.

- Power and water supply.

- Testing and commissioning.

- Feed material.

- Monitoring and controlling process parameters.

- Maintenance and troubleshooting.

- Waste management.

- Safety precautions.

4. What are the common problems that you encounter when operating a gravel screening plant and how do you troubleshoot them?

- Blockages in the feed chute.

- Clogged screens.

- Incorrect screen size.

- Mechanical breakdowns.

- Electrical problems.

5. How do you maintain a gravel screening plant to ensure optimal performance?

- Regular inspection of all components.

- Cleaning and lubrication of all moving parts.

- Tightening of bolts and nuts.

- Replacement of worn or damaged parts.

- Calibration of sensors and instruments.

6. What are the safety precautions that you should observe when working in a gravel screening plant?

- Wear appropriate personal protective equipment (PPE) such as hard hat, safety glasses, earplugs, and gloves.

- Be aware of your surroundings and potential hazards.

- Do not operate the machine if you are not trained or authorized.

- Follow all safety procedures and guidelines.

- Report any accidents or near misses immediately.

7. What are the environmental regulations that apply to the operation of a gravel screening plant?

- Air pollution control regulations.

- Water pollution control regulations.

- Waste management regulations.

- Noise pollution control regulations.

8. What are the quality control procedures that you follow to ensure the quality of the screened gravel?

- Visual inspection of the screened gravel.

- Sieve analysis of the screened gravel.

- Comparison of the screened gravel to the desired specifications.

- Adjustment of the screening process as needed.

9. What are the different types of materials that can be screened using a gravel screen?

- Gravel

- Sand

- Soil

- Recycled concrete

- Recycled asphalt

10. What are the benefits of using a gravel screening plant?

- Improved product quality.

- Increased production efficiency.

- Reduced operating costs.

- Reduced waste.

- Improved environmental compliance.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Gravel Screener.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Gravel Screener‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Gravel Screeners are responsible for operating, maintaining, and repairing gravel screening equipment. They ensure that the gravel meets the required specifications, and they maintain a safe and efficient work environment.

1. Operating Gravel Screening Equipment

Gravel Screeners operate a variety of screening equipment, including vibrating screens, trommel screens, and grizzly screens. They adjust the equipment to achieve the desired screening results, and they monitor the equipment to ensure that it is operating properly.

- Operate vibrating screens, trommel screens, and grizzly screens

- Adjust equipment to achieve desired screening results

- Monitor equipment to ensure proper operation

2. Maintaining Gravel Screening Equipment

Gravel Screeners maintain the screening equipment to ensure that it is in good working order. They lubricate moving parts, replace worn or damaged components, and make repairs as needed. They also keep the equipment clean and free of debris.

- Lubricate moving parts

- Replace worn or damaged components

- Make repairs as needed

- Keep equipment clean and free of debris

3. Ensuring Gravel Meets Specifications

Gravel Screeners ensure that the gravel meets the required specifications. They test the gravel to determine its size, shape, and other characteristics. They make adjustments to the screening equipment as needed to ensure that the gravel meets the desired specifications.

- Test gravel to determine size, shape, and other characteristics

- Make adjustments to screening equipment as needed

- Ensure gravel meets desired specifications

4. Maintaining a Safe and Efficient Work Environment

Gravel Screeners maintain a safe and efficient work environment. They follow safety procedures, and they use personal protective equipment. They also keep the work area clean and organized.

- Follow safety procedures

- Use personal protective equipment

- Keep work area clean and organized

Interview Tips

Here are some tips to help you ace your interview for a Gravel Screener position:

1. Research the Position and Company

Before your interview, take some time to research the gravel screener position and the company you are applying to. This will help you understand the company’s culture and the specific requirements of the position. You can find information about the company on their website, in industry publications, or by talking to people who work there.

- Research the gravel screener position

- Research the company you are applying to

- Understand the company’s culture

- Identify the specific requirements of the position

2. Highlight Your Experience

In your interview, be sure to highlight your experience operating and maintaining gravel screening equipment. Describe your skills in detail, and provide specific examples of how you have used these skills to improve safety and efficiency.

- Highlight your experience operating and maintaining gravel screening equipment

- Describe your skills in detail

- Provide specific examples of how you have used these skills to improve safety and efficiency

3. Demonstrate Your Safety Awareness

Gravel screeners must be aware of the potential hazards associated with their work. In your interview, be sure to demonstrate your safety awareness and your commitment to following safety procedures. You can do this by discussing your experience with safety training and your record of safe work practices.

- Demonstrate your safety awareness

- Discuss your experience with safety training

- Highlight your record of safe work practices

4. Be Prepared to Answer Common Interview Questions

In addition to the questions specific to the gravel screener position, you should also be prepared to answer common interview questions such as:

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What are your career goals?

- Why should we hire you?

5. Dress Professionally

First impressions matter, so be sure to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for a business setting. You should also arrive on time for your interview and be polite and respectful to the interviewer.

- Dress professionally

- Arrive on time for your interview

- Be polite and respectful to the interviewer

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Gravel Screener interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!