Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Grease Worker interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Grease Worker so you can tailor your answers to impress potential employers.

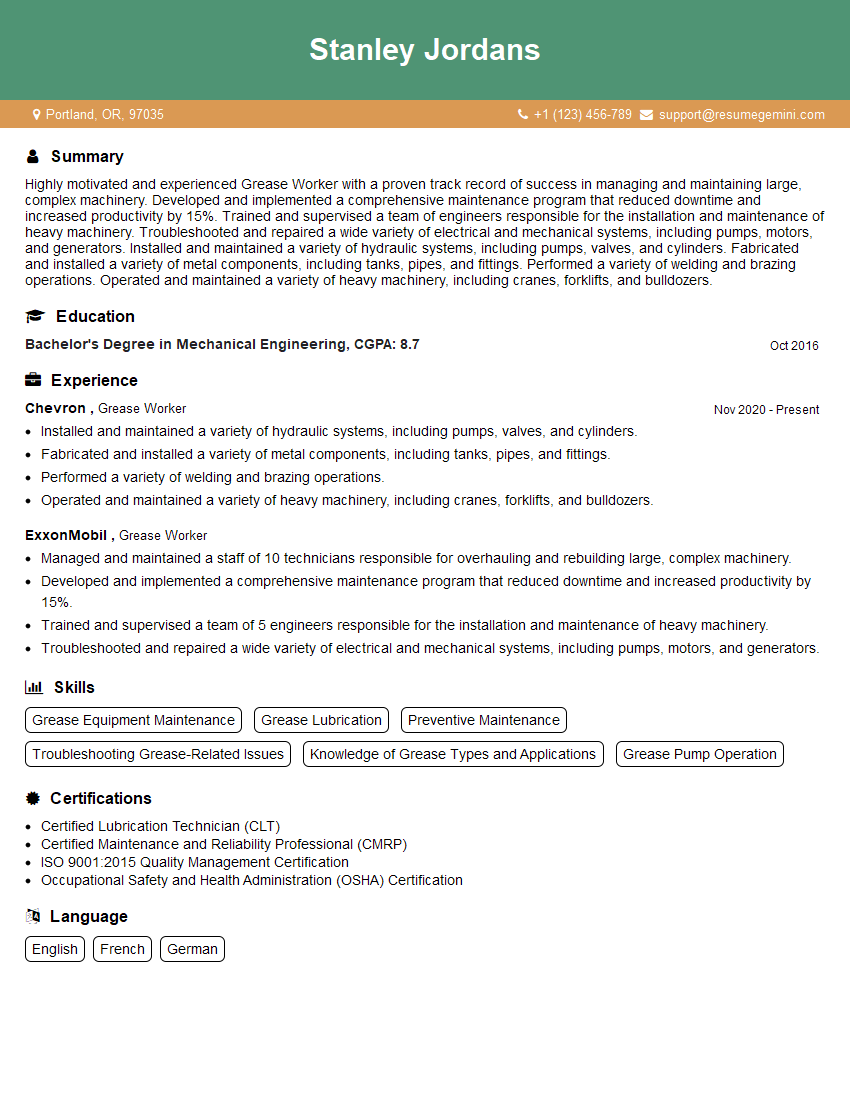

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Grease Worker

1. Explain the purpose and importance of greasing equipment?

- Greasing equipment reduces friction and wear between moving parts, extending their lifespan.

- It prevents corrosion and rust, protecting equipment from damage due to moisture and oxidation.

- Greasing improves efficiency by reducing resistance and power consumption.

- It minimizes noise and vibration, creating a more pleasant work environment.

- Proper greasing ensures equipment operates smoothly and reliably, minimizing downtime and maintenance costs.

2. Describe the different types of greases and their applications?

Types of Greases

- Lithium-based: General-purpose, high-temperature, and water-resistant.

- Sodium-based: High-pressure, shock-resistant, and suitable for wet environments.

- Calcium-based: Extreme high-temperature applications, water-repellent.

Applications

- Automotive: Bearings, joints, chassis components

- Industrial: Gearboxes, pumps, motors

- Aerospace: High-temperature, friction-critical applications

- Marine: Water-resistant and corrosion-protective

3. What are the key factors to consider when selecting a grease?

- Operating temperature: Ensure grease is suitable for the equipment’s temperature range.

- Load and speed: Choose grease with appropriate viscosity for the load and speed of the application.

- Environment: Consider exposure to moisture, chemicals, or extreme conditions.

- Equipment type: Some greases are specifically designed for certain types of equipment or applications.

- Manufacturer recommendations: Refer to equipment manuals for specific grease specifications.

4. Explain the proper procedure for greasing equipment?

- Clean: Remove old grease and dirt from the greasing point.

- Apply: Use a grease gun or brush to apply grease sparingly.

- Distribute: Operate the equipment to distribute grease evenly.

- Check: Monitor equipment operation to ensure proper lubrication.

- Lubrication intervals: Follow manufacturer’s recommendations or observe equipment performance.

5. What are the common signs of under-lubrication and over-lubrication?

Under-lubrication

- Increased friction and wear

- Squeaking or grinding noises

- Premature equipment failure

Over-lubrication

- Leaking or oozing grease

- Attracting dirt and contaminants

- Overheating due to increased friction

6. Describe the importance of grease analysis and how it can benefit equipment maintenance?

- Deterioration monitoring: Grease analysis detects changes in grease properties, indicating the need for replacement.

- Contamination detection: It identifies contaminants that can damage equipment.

- Wear analysis: Grease analysis can reveal metal particles, indicating excessive wear or damage.

- Optimization: By monitoring grease condition, maintenance intervals can be optimized, reducing downtime and costs.

- Troubleshooting: Grease analysis can help identify the cause of equipment failures and guide corrective actions.

7. Explain the safety precautions that must be followed when working with greases?

- Wear protective gear: Use gloves, safety glasses, and overalls.

- Avoid skin contact: Greases can irritate the skin.

- Handle properly: Use clean containers and tools, and dispose of grease responsibly.

- Avoid cross-contamination: Ensure different grease types are not mixed.

- Ventilate: Work in well-ventilated areas, especially when spraying grease.

8. Describe the impact of proper greasing on energy efficiency?

- Friction reduction: Proper greasing reduces friction, lowering energy consumption.

- Efficiency improvement: Reduced friction improves equipment efficiency, resulting in energy savings.

- Extended equipment life: Proper greasing prolongs equipment life, reducing energy spent on replacements.

- Predictive maintenance: Grease analysis and regular greasing enable predictive maintenance, preventing catastrophic failures and energy loss.

9. Explain the environmental considerations related to greasing equipment?

- Biodegradable greases: Use biodegradable greases to minimize environmental impact.

- Responsible disposal: Dispose of used grease and empty containers according to local regulations.

- Avoid over-greasing: Prevent grease leaks and spills that can contaminate soil and water.

- Lubrication management: Implement a lubrication management program to optimize greasing intervals and reduce waste.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Grease Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Grease Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Grease Workers are responsible for the smooth operation and maintenance of machinery and equipment in various industries, including manufacturing, automotive, and transportation. Their primary responsibilities revolve around lubrication, inspection, and monitoring to ensure efficient and safe functioning.

1. Lubrication and Maintenance

Grease Workers are responsible for identifying and applying the appropriate lubricants to machinery and equipment, using grease guns or other tools. They ensure that all moving parts are adequately lubricated to reduce friction, prevent wear and tear, and extend the lifespan of the equipment.

- Determine the type and quantity of lubricant required for specific machinery.

- Use grease guns or other tools to apply lubricant to designated points.

- Inspect and maintain lubrication systems, including grease nipples and reservoirs.

2. Inspection and Monitoring

Grease Workers regularly inspect machinery and equipment to identify potential issues or safety hazards. They check for signs of wear, damage, or leakage and report any abnormalities to supervisors or maintenance crews. By monitoring the performance of equipment, they help prevent breakdowns and ensure optimal operation.

- Inspect machinery for any signs of damage, wear, or corrosion.

- Monitor equipment performance and record observations.

- Identify and report potential problems or safety hazards.

3. Equipment Repair and Troubleshooting

In some cases, Grease Workers may be responsible for minor equipment repairs and troubleshooting. They use their knowledge of machinery and lubrication to identify and fix simple issues, reducing downtime and maintaining productivity. However, more complex repairs typically require the expertise of skilled mechanics.

- Troubleshoot minor equipment malfunctions.

- Perform basic repairs, such as tightening bolts or replacing seals.

- Identify and report more complex issues to supervisors or maintenance crews.

4. Safety and Environmental Compliance

Grease Workers are responsible for maintaining a safe and clean work environment. They adhere to established safety protocols and use personal protective equipment to minimize risks. They also follow environmental regulations regarding the handling and disposal of lubricants.

- Follow safety guidelines and use personal protective equipment.

- Maintain a clean and organized work area.

- Dispose of used lubricants and waste materials properly.

Interview Tips

Preparing thoroughly for a Grease Worker interview can significantly increase your chances of success. Here are some tips and hacks to help you ace the interview:

1. Research the Company and Job Description

Take the time to gather information about the company you are applying to, including their industry, values, and recent news. This will demonstrate your interest and show that you have taken the interview process seriously. Additionally, carefully review the job description to identify the key requirements and responsibilities of the role.

- Visit the company’s website and social media pages.

- Read industry news and articles to stay informed about the company’s sector.

- Highlight in your resume and cover letter how your skills and experience align with the job requirements.

2. Practice Common Interview Questions

Preparing for common interview questions will help you feel more confident and organized during your interview. Anticipate questions about your experience in machinery lubrication, inspection, and safety procedures. You can also expect questions about your problem-solving and troubleshooting abilities.

- Prepare answers to questions about your experience and skills.

- Practice using the STAR (Situation, Task, Action, Result) method to structure your answers.

- Use examples from your previous roles to demonstrate your capabilities.

3. Emphasize Your Attention to Detail

Grease Workers must be highly attentive to detail to ensure that machinery is properly lubricated and maintained. Highlight your ability to notice subtle changes or potential issues during your interview. Provide examples of how you have identified and resolved problems in the past.

- Explain your methods for inspecting machinery and identifying potential problems.

- Describe a situation where you identified and resolved a problem with machinery.

- Explain how your attention to detail has contributed to the smooth operation of machinery in previous roles.

4. Highlight Your Safety Consciousness

Safety is paramount in industrial environments, and Grease Workers must be safety-conscious and follow established protocols. Emphasize your commitment to safety during the interview. Explain your understanding of safety regulations and your experience in maintaining a safe work environment.

- Explain your understanding of industry safety standards and regulations.

- Describe how you have implemented safety procedures in previous roles.

- Provide examples of how you have identified and addressed potential safety hazards.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Grease Worker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!