Feeling lost in a sea of interview questions? Landed that dream interview for Greaser but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Greaser interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

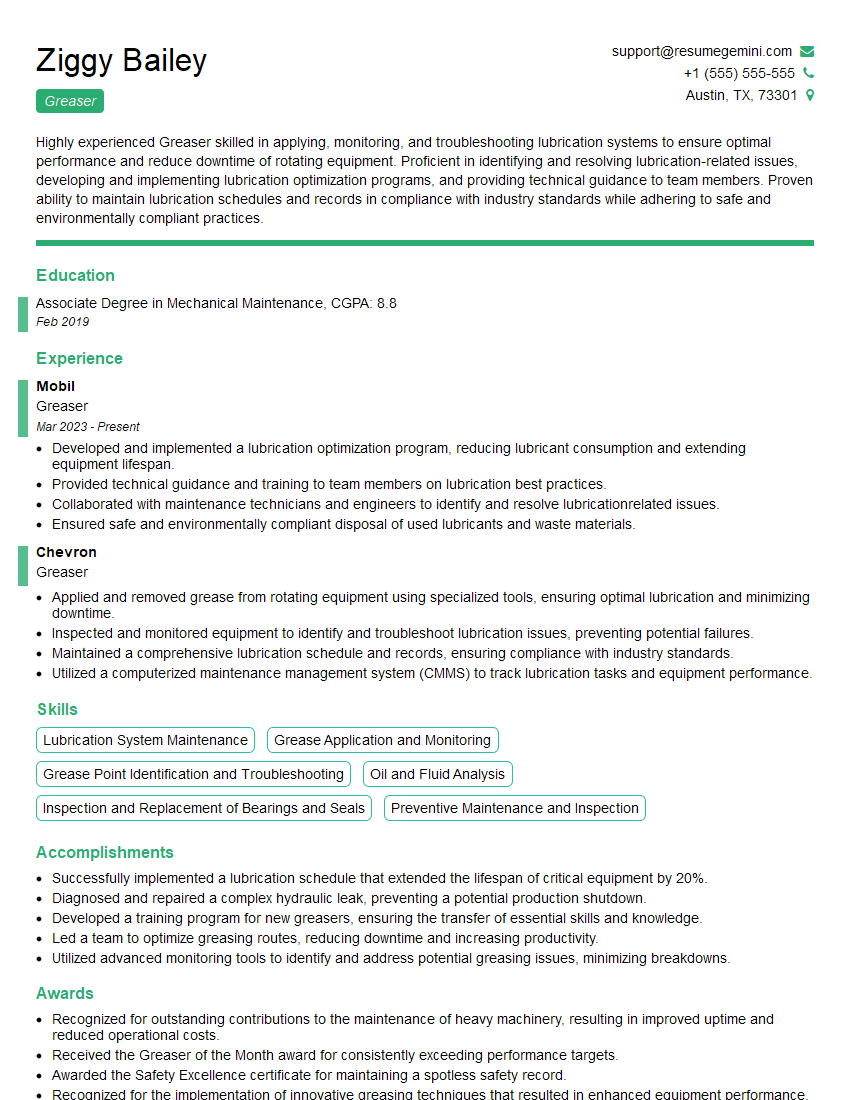

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Greaser

1. What are the different types of greases and their applications?

There are many different types of greases, each with its own unique set of properties and applications. Some of the most common types of greases include:

- Lithium-based greases: These greases are commonly used in automotive and industrial applications. They are known for their good water resistance and high-temperature performance.

- Calcium-based greases: These greases are often used in food-grade applications. They are known for their low toxicity and good corrosion resistance.

- Sodium-based greases: These greases are known for their high water resistance and extreme pressure performance. They are often used in marine and heavy-duty industrial applications.

- Synthetic greases: These greases are made from synthetic hydrocarbons or other non-petroleum-based materials. They are known for their wide temperature range and long service life.

2. What are the important properties of a grease?

Performance Properties

- Consistency: The consistency of a grease is a measure of its hardness or softness. It is typically measured using the National Lubricating Grease Institute (NLGI) scale, which ranges from 000 (very soft) to 6 (very hard).

- Dropping point: The dropping point of a grease is the temperature at which it changes from a solid to a liquid. It is an important property for greases that are used in high-temperature applications.

- Oil separation: Oil separation is the tendency of a grease to release oil over time. It is an important property for greases that are used in applications where oil leakage is a concern.

- Water resistance: The water resistance of a grease is its ability to withstand the effects of water. It is an important property for greases that are used in wet or humid environments.

- Extreme pressure performance: The extreme pressure performance of a grease is its ability to withstand high loads and prevent wear. It is an important property for greases that are used in heavy-duty applications.

Application properties

- Compatibility: The compatibility of a grease is its ability to be used with other materials, such as metals, plastics, and rubbers. It is important to consider the compatibility of a grease with the materials that it will be used with before applying it.

- Adhesion: The adhesion of a grease is its ability to stick to surfaces. It is an important property for greases that are used in applications where the grease must stay in place under high loads or vibration.

- Cost: The cost of a grease is an important factor to consider when selecting a grease for a specific application. There are a wide range of greases available at different price points.

3. What are the different methods of applying grease?

There are a variety of methods that can be used to apply grease, including:

- Hand application: Grease can be applied by hand using a brush, spatula, or other tool. This method is suitable for small applications or for applying grease to hard-to-reach areas.

- Grease gun: A grease gun is a tool that is used to apply grease under pressure. Grease guns are available in a variety of sizes and types, and they can be used to apply grease to a wide range of applications.

- Automated grease systems: Automated grease systems are used to apply grease to a variety of applications, such as bearings, gears, and chains. These systems can be programmed to apply grease at regular intervals, and they can help to reduce the risk of equipment failure.

4. What are the common problems associated with grease?

There are a number of common problems that can be associated with grease, including:

- Oil leakage: Grease can leak out of bearings and other components if it is not properly applied or if the seals are damaged.

- Grease hardening: Grease can harden over time, which can make it difficult to apply and can reduce its performance.

- Contamination: Grease can become contaminated with dirt, dust, and other particles, which can reduce its performance and lead to equipment failure.

5. What are the best practices for grease lubrication?

There are a number of best practices that should be followed when lubricating with grease, including:

- Use the correct type of grease for the application.

- Apply the grease correctly using the appropriate method.

- Lubricate bearings and other components at regular intervals.

- Inspect and clean grease fittings regularly.

- Monitor the condition of the grease and replace it if necessary.

6. What are the latest trends in grease technology?

There are a number of new and emerging trends in grease technology, including:

- The development of new synthetic greases with improved performance properties.

- The development of new grease application methods, such as automated grease systems.

- The use of grease in new and innovative applications, such as wind turbines and electric vehicles.

7. What are the challenges facing the grease industry?

The grease industry is facing a number of challenges, including:

- The increasing demand for grease in new and emerging applications.

- The need to develop new greases with improved performance properties.

- The need to reduce the environmental impact of grease.

8. What are the opportunities for growth in the grease industry?

There are a number of opportunities for growth in the grease industry, including:

- The growing demand for grease in developing countries.

- The development of new and innovative grease applications.

- The increasing awareness of the importance of grease lubrication.

9. What are your strengths and weaknesses as a grease technician?

My strengths as a grease technician include my:

- In-depth knowledge of grease technology.

- Experience in a variety of grease applications.

- Strong problem-solving skills.

- Excellent communication skills.

My weaknesses include my:

- Limited experience in some specialized grease applications.

- I am still learning about the latest trends in grease technology.

10. What are your career goals as a grease technician?

My career goals as a grease technician are to:

- Become a certified grease technician.

- Gain experience in a variety of grease applications.

- Develop my problem-solving and communication skills.

- Become a leader in the grease industry.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Greaser.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Greaser‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Grease machinery and equipment to minimize friction, wear, and corrosion. Ensure that all moving parts are properly lubricated and free of debris.

1. Lubrication Management

Select and apply appropriate lubricants based on manufacturer’s specifications and operating conditions.

- Monitor lubrication levels and schedules to prevent equipment damage.

- Conduct regular inspections to identify potential lubrication issues.

2. Equipment Maintenance

Perform minor repairs and adjustments on machinery and equipment under supervision, such as tightening bolts, clearing blockages, and replacing gaskets.

- Identify and report any major maintenance or repair needs.

- Assist with scheduled maintenance activities.

3. Safety and Compliance

Adhere to safety protocols and environmental regulations related to lubrication and maintenance.

- Wear appropriate personal protective equipment (PPE).

- Use environmentally friendly lubricants and dispose of used lubricants properly.

4. Record Keeping

Maintain accurate records of lubrication activities, including types of lubricants used, application dates, and equipment performance.

- Document inspections, repairs, and maintenance activities.

- Provide reports on lubrication schedules and equipment condition.

Interview Tips

Preparing for a greaser interview requires careful research and practice. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Familiarize yourself with the company’s history, products, and industry trends. This will enable you to demonstrate your understanding of the role.

- Visit the company’s website and social media pages.

- Read industry magazines and news articles.

2. Practice Common Interview Questions

Expect to be asked about your experience, skills, and knowledge. Prepare answers to common interview questions:

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses as a greaser?

- Describe a time you successfully lubricated and maintained equipment.

3. Highlight Relevant Skills and Experience

Emphasize your skills in equipment maintenance, lubrication, and safety. Share examples from your previous experience that demonstrate your abilities.

- Quantify your results whenever possible, using specific numbers and metrics.

- Be prepared to discuss your experience with different types of equipment.

4. Show Enthusiasm and a Learning Mindset

Exhibit enthusiasm for the greaser role and a commitment to learning and improving.

- Express your interest in staying up-to-date with industry best practices.

- Share examples of how you have proactively pursued professional development opportunities.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Greaser interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!