Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Grey Iron Molder position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

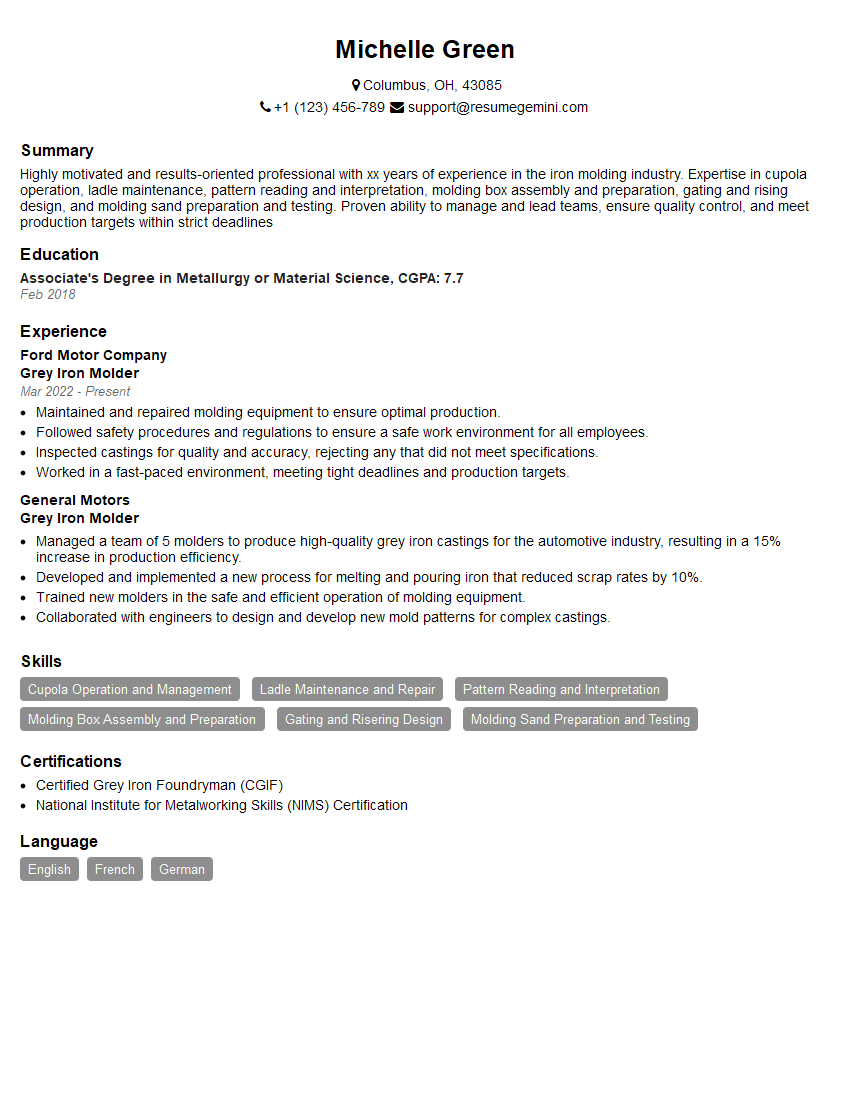

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Grey Iron Molder

1. Explain the process of making grey iron castings?

Grey iron casting involves several steps:

- Pattern making: Creating a wooden or metal pattern that determines the shape of the casting.

- Sand preparation: Mixing sand with binders and forming it around the pattern to create a mold.

- Melting and pouring: Melting grey iron in a furnace and pouring it into the mold.

- Cooling and solidification: Allowing the molten iron to cool and solidify within the mold.

- Shakeout: Removing the casting from the mold after cooling.

- Finishing: Removing any excess sand, grinding, and inspecting the casting.

2. Describe the properties of grey iron?

Grey iron is a type of cast iron with the following properties:

- High compressive strength: Excellent ability to withstand compressive forces.

- Good machinability: Can be easily machined and cut.

- Damping capacity: Ability to absorb and dissipate vibrations.

- Low tensile strength: Relatively weak under tensile forces.

- Grey fracture surface: Exhibits a grey, flake-like fracture surface.

3. What are the common defects found in grey iron castings?

Some common defects in grey iron castings include:

- Shrinkage porosity: Voids caused by uneven cooling and shrinkage during solidification.

- Gas porosity: Bubbles or voids formed by gases trapped during casting.

- Cold shuts: Unfused areas where molten iron fails to join properly.

- Sand inclusions: Sand particles trapped in the casting due to mold imperfections.

- Cracks: Fractures that can occur during cooling or due to external forces.

4. How do you control the quality of grey iron castings?

Quality control in grey iron casting involves:

- Raw material inspection: Checking the composition and quality of raw materials.

- Mold preparation: Ensuring proper mold design, sand properties, and compaction.

- Melting and pouring: Controlling furnace temperature, pouring temperature, and solidification rates.

- Post-casting inspection: Examining castings for defects, dimensions, and surface finish.

- Non-destructive testing: Using techniques like radiography or ultrasonic testing to detect internal defects.

5. What are the different grades of grey iron?

Grey iron is classified into grades based on its tensile strength:

- Class 20: 20,000 psi tensile strength.

- Class 25: 25,000 psi tensile strength.

- Class 30: 30,000 psi tensile strength.

- Class 35: 35,000 psi tensile strength.

- Class 40: 40,000 psi tensile strength.

6. What are the applications of grey iron castings?

Grey iron castings find applications in various industries:

- Automotive: Engine blocks, crankshafts, brake discs.

- Construction: Pipes, fittings, building materials.

- Machinery: Machine frames, gears, pumps.

- Appliances: Stoves, washing machines.

- Others: Weights, counterweights, sculptures.

7. How do you troubleshoot casting defects?

Troubleshooting casting defects involves:

- Identifying the defect type: Examining the casting and analyzing its characteristics.

- Determining the cause: Investigating the mold design, melting practices, and casting process.

- Implementing corrective actions: Adjusting mold parameters, modifying melting conditions, or improving pouring techniques.

- Verifying the solution: Trial runs or inspection methods to ensure the defect is resolved.

8. Describe the importance of mold design in grey iron casting?

Mold design plays a crucial role in casting quality:

- Casting shape and dimensions: Accurately defining the geometry and size of the casting.

- Gating and risering: Designing proper channels for molten iron flow and feeders to prevent shrinkage defects.

- Mold stability: Ensuring the mold can withstand the pouring and solidification forces without cracking.

- Venting: Providing channels for gases to escape during casting to prevent porosity.

9. How do you optimize melting practices for grey iron casting?

Optimizing melting practices involves several factors:

- Charge materials: Selecting the appropriate scrap, pig iron, and alloys based on desired composition.

- Furnace type: Choosing the right furnace for the melting process, such as induction or electric arc furnace.

- Temperature control: Maintaining the correct melting and pouring temperatures to achieve optimal fluidity and microstructure.

- Chemical composition: Adjusting the alloying elements, such as carbon, silicon, and manganese, to meet the desired properties.

10. Discuss the advantages and disadvantages of grey iron compared to other materials?

Grey iron has both advantages and disadvantages compared to other materials:

Advantages:

- Low cost: Relatively inexpensive compared to other metals.

- Good damping capacity: Absorbs vibrations well.

- Machinability: Can be easily machined and shaped.

Disadvantages:

- Low tensile strength: Not as strong as other materials under tensile forces.

- Brittle: Can fracture if subjected to shock or impact.

- High carbon content: Can lead to corrosion issues if not properly protected.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Grey Iron Molder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Grey Iron Molder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Grey Iron Molders are responsible for producing iron castings using a variety of techniques and equipment. Their primary responsibilities include:

1. Mold Making

Creating molds using sand, metal, or other materials to shape molten iron into desired forms.

2. Pouring Molten Iron

Operating furnaces to melt iron and pouring it into molds, ensuring proper temperature and flow.

3. Cooling and Solidification

Controlling the cooling process to ensure proper solidification and prevent defects in castings.

4. Casting Finishing

Inspecting castings for flaws, removing excess material, and preparing them for further processing or shipment.

5. Equipment Maintenance

Maintaining and calibrating equipment, including furnaces, mold-making machines, and conveyors.

6. Quality Control

Ensuring the quality of castings by adhering to specifications, inspecting for defects, and making necessary adjustments.

7. Safety Compliance

Maintaining a safe work environment by following proper procedures, wearing protective gear, and handling hazardous materials responsibly.

Interview Tips

To ace the interview for a Grey Iron Molder position, candidates should focus on highlighting their technical skills, experience, and commitment to safety. Here are some tips to help:

1. Research the Company and Industry

Familiarize yourself with the company’s products, services, and market position. Research the industry trends and challenges to demonstrate your knowledge.

2. Emphasize Technical Skills

Highlight your proficiency in mold-making techniques, molten iron handling, and quality control procedures. Provide specific examples of your work and the results you achieved.

3. Showcase Safety Commitment

Emphasize your understanding of safety protocols and your commitment to maintaining a safe work environment. Describe your experience in using protective gear, handling hazardous materials, and following proper procedures.

4. Prepare for Behavioral Questions

Practice answering questions that explore your teamwork, problem-solving abilities, and attention to detail. Use the STAR method (Situation, Task, Action, Result) to provide structured and compelling responses.

5. Ask Insightful Questions

At the end of the interview, ask thoughtful questions to demonstrate your interest in the position and the company. This shows that you are engaged and eager to learn more.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Grey Iron Molder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!