Are you gearing up for a career in Gridcap Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Gridcap Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

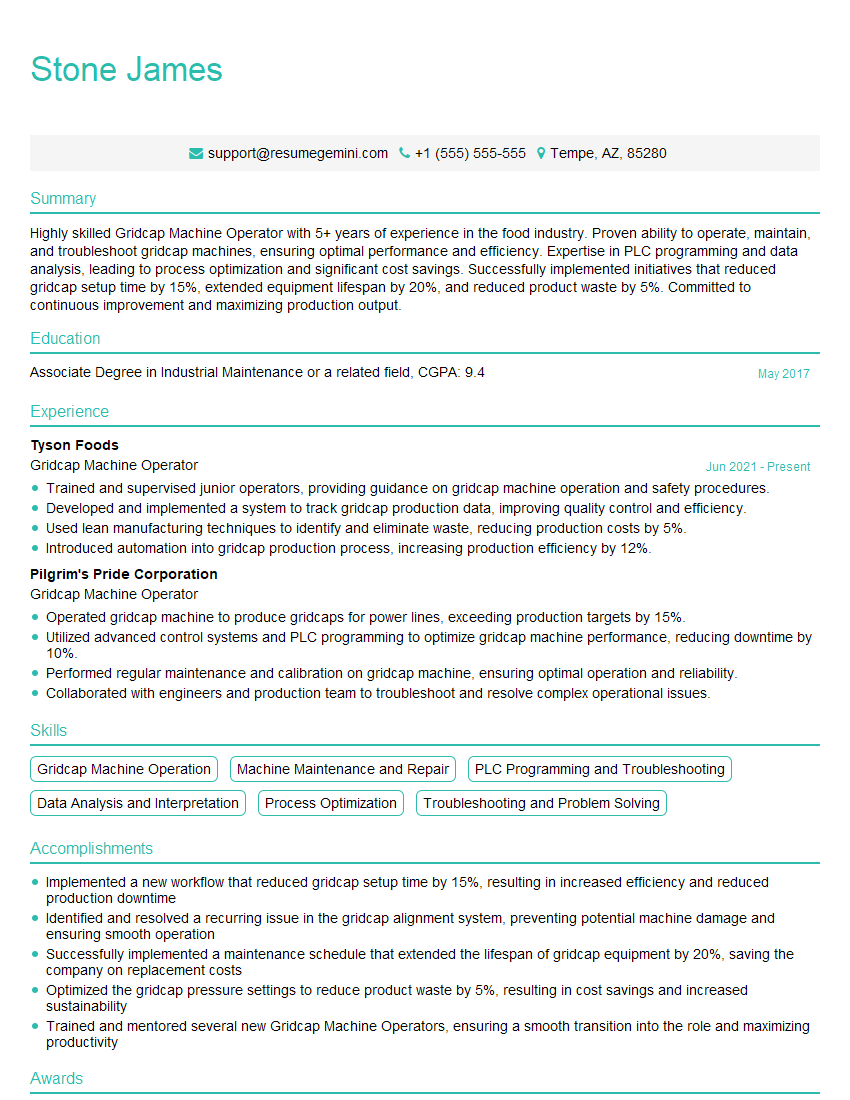

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Gridcap Machine Operator

1. Can you describe the process of setting up and operating a Gridcap machine?

The process of setting up and operating a Gridcap machine involves several key steps:

- Job Preparation: Reviewing the job specifications, selecting the appropriate tooling, and ensuring that the machine is calibrated and ready for operation.

- Material Loading: Loading the raw material onto the machine’s table, aligning it precisely, and securing it in place.

- Program Execution: Inputting the CNC program into the machine’s controller, verifying the parameters, and initiating the cutting process.

- Monitoring and Adjustment: Continuously monitoring the machine’s performance, making necessary adjustments to the cutting parameters, and ensuring optimal operation.

- Part Removal: Once the cutting process is complete, unloading the finished part, inspecting it for quality, and preparing it for further processing or shipment.

2. How do you ensure the accuracy and precision of the parts produced on a Gridcap machine?

Calibration and Maintenance:

- Regularly calibrating the machine to maintain its accuracy and precision.

- Performing routine maintenance tasks, such as spindle inspection, lubrication, and tool replacement, to prevent errors.

Tooling Selection and Setup:

- Selecting the appropriate cutting tools for the specific material and job requirements.

- Properly installing and setting up the tools to ensure precision cutting.

Program Optimization:

- Optimizing the CNC programs to minimize errors and improve cutting efficiency.

- Verifying the program parameters, including feed rates, spindle speeds, and tool paths, before execution.

3. What are the common troubleshooting procedures for Gridcap machines?

Troubleshooting Gridcap machines involves a systematic approach to identifying and resolving issues:

- Mechanical Problems: Checking for loose connections, worn components, or lubrication issues.

- Electrical Faults: Inspecting electrical connections, wiring, and circuit boards for damage or malfunctions.

- Software Errors: Verifying the CNC program for errors, checking the machine’s settings, and updating software if necessary.

- Tooling Issues: Inspecting cutting tools for wear or damage, ensuring proper tool setup, and adjusting cutting parameters.

4. How do you optimize the cutting process of a Gridcap machine for different materials and applications?

Optimizing the cutting process involves adjusting various parameters to achieve the desired results:

- Material Properties: Selecting the appropriate cutting tools and parameters based on the material’s hardness, toughness, and machinability.

- Application Anforderungen: Determining the required precision, surface finish, and production rate for the specific application.

- Tool Selection: Choosing the optimal cutting tool geometry, material, and coatings to maximize tool life and cutting efficiency.

- Cutting Parameters: Adjusting feed rates, spindle speeds, and tool paths to optimize the cutting process and minimize cycle times.

5. Explain the importance of safety when operating a Gridcap machine.

Safety is paramount when operating a Gridcap machine:

- Proper Training: Receiving thorough training on the machine’s operation, safety features, and emergency procedures.

- Protective Gear: Wearing appropriate safety gear, including safety glasses, earplugs, and gloves, to minimize risks.

- Machine Maintenance: Regularly inspecting and maintaining the machine to ensure its safe operation.

- Work Area Safety: Keeping the work area clean, free of tripping hazards, and well-ventilated.

- Emergency Preparedness: Familiarizing oneself with emergency stop procedures and knowing where to seek help in case of accidents.

6. Describe the different types of Gridcap machines and their applications.

- Vertical Gridcap Machines: Designed for high-volume production, offering fast cycle times and high precision for complex parts.

- Horizontal Gridcap Machines: Suitable for larger workpieces and heavy-duty machining operations, providing high torque and stability.

- Multi-Axis Gridcap Machines: Capable of multiple simultaneous machining operations, reducing setup time and increasing productivity.

- Specialty Gridcap Machines: Designed for specific applications, such as mold making, die sinking, and high-speed cutting.

7. How do you stay updated with the latest advancements in Gridcap technology and best practices?

- Industry Events: Attending trade shows, conferences, and workshops to learn about new technologies and industry trends.

- Technical Publications: Reading industry magazines, journals, and technical articles to stay informed about advancements.

- Online Resources: Exploring manufacturer websites, online forums, and social media groups for the latest information.

- Training and Certification: Participating in training programs and obtaining certifications to enhance skills and knowledge.

- Collaboration: Engaging with colleagues, industry experts, and equipment suppliers to exchange ideas and share best practices.

8. Can you describe the role of CAD/CAM software in Gridcap machine operation?

CAD/CAM software plays a crucial role in Gridcap machine operation:

- Design and Modeling: Creating 3D models of parts and assemblies using CAD software.

- CAM Programming: Generating CNC programs from the CAD models, specifying tool paths, cutting parameters, and machine movements.

- Simulation: Simulating the cutting process virtually to detect potential errors and optimize the program before execution.

- Data Management: Storing and managing CAD/CAM data, including part files, programs, and tool libraries.

- Integration: Interfacing with the Gridcap machine’s controller to transfer CNC programs and monitor the machining process.

9. How do you measure and ensure the quality of parts produced on a Gridcap machine?

- Inspection: Using precision measuring tools, such as calipers, micrometers, and CMMs, to verify part dimensions, tolerances, and surface finish.

- Quality Control: Implementing quality control procedures to monitor the production process and identify deviations from specifications.

- Statistical Process Control: Using statistical techniques to analyze production data, identify trends, and make adjustments to improve quality.

- Calibration and Certification: Regularly calibrating measuring equipment and maintaining certifications to ensure accuracy and reliability.

- Customer Feedback: Gathering customer feedback and using it to identify areas for quality improvement.

10. Can you explain the concept of G-code and its importance in Gridcap machine operation?

G-code is a programming language used to control Gridcap machines:

- Program Structure: G-code programs consist of a series of commands that define tool movements, cutting parameters, and machine functions.

- Motion Control: G-code commands specify the linear and circular movements of the cutting tool along the X, Y, and Z axes.

- Tool Control: G-code commands control tool selection, spindle speed, and feed rate.

- Auxiliary Functions: G-code commands can also control auxiliary functions, such as coolant on/off, tool changes, and program branching.

- Optimization: Skilled Gridcap operators can optimize G-code programs to improve efficiency, reduce cycle times, and enhance part quality.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Gridcap Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Gridcap Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Gridcap Machine Operator is accountable for effectively operating and managing a gridcap machine, a specialized manufacturing equipment used to produce gridcaps, which are protective covers for electric wires and cables.

1. Machine Operation and Maintenance

Operate the gridcap machine proficiently to produce gridcaps according to specifications.

- Set up and calibrate the machine, ensuring precise operation and product quality.

- Monitor the machine during operation, identify and address any issues promptly to maintain optimal performance.

2. Quality Control

Perform regular quality checks on the produced gridcaps.

- Inspect gridcaps for defects, ensuring they meet the established standards.

- Record and report any quality issues to the supervisor promptly.

3. Materials Handling

Handle materials related to gridcap production efficiently.

- Load and unload raw materials into the machine.

- Manage finished products, packaging them appropriately for storage or shipment.

4. Safety and Housekeeping

Maintain a safe and organized work environment.

- Follow all safety protocols and regulations.

- Keep the work area clean and organized to prevent accidents and ensure efficient operations.

Interview Tips

To ace the interview for a Gridcap Machine Operator position, candidates should prepare thoroughly and demonstrate their skills and qualifications effectively.

1. Research the Company and Position

Familiarize yourself with the company’s background, industry, and values. Research the specific role and responsibilities to understand the expected duties and requirements.

2. Highlight Relevant Experience

Emphasize your previous experience operating gridcap machines or similar manufacturing equipment. Quantify your accomplishments whenever possible, using specific metrics to showcase your impact.

3. Demonstrate Quality Control Expertise

Discuss your knowledge of quality control procedures and highlight your ability to identify and resolve product defects. Provide examples of how you have maintained high quality standards in previous roles.

4. Emphasize Safety Consciousness

Stress your commitment to safety and adherence to regulations. Share examples of your safety practices and how you promote a safe work environment.

5. Communicate Effectively

Throughout the interview, demonstrate your clear and concise communication skills. Explain your ideas and experiences articulately, and be prepared to answer questions in a professional and engaging manner.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Gridcap Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.