Are you gearing up for an interview for a Grinder Chipper position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Grinder Chipper and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

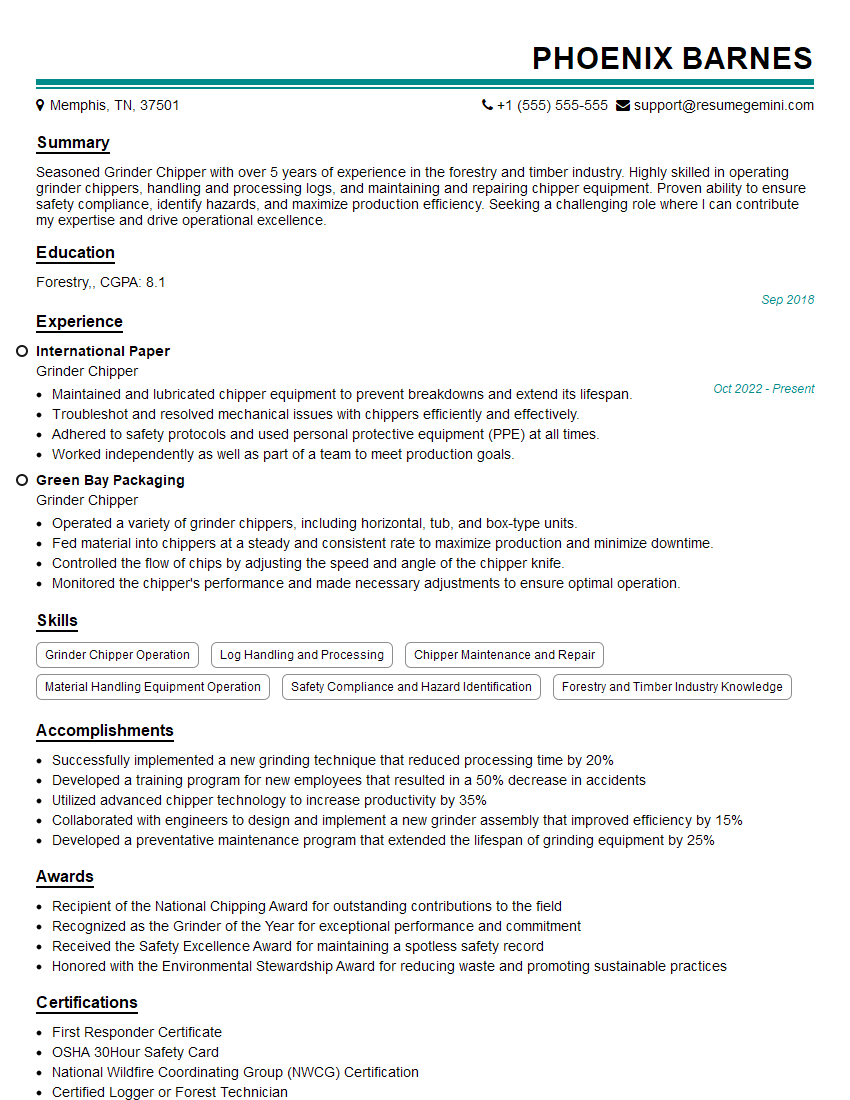

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Grinder Chipper

1. What are the key components of a grinder chipper machine?

The key components of a grinder chipper machine include:

- Hopper: The hopper is where the material to be ground is fed into the machine.

- Cutting blades: The cutting blades are responsible for cutting the material into smaller pieces.

- Discharge chute: The discharge chute is where the ground material is discharged from the machine.

- Engine: The engine provides the power to operate the machine.

- Hydraulic system: The hydraulic system powers the cutting blades and other components of the machine.

2. How do you maintain a grinder chipper machine?

Daily maintenance

- Check the oil level and add oil if necessary.

- Check the air filter and clean or replace it if necessary.

- Check the cutting blades for wear and sharpen or replace them if necessary.

- Check the hydraulic system for leaks and repair any leaks if necessary.

Weekly maintenance

- Clean the hopper and discharge chute.

- Lubricate the cutting blades and other moving parts.

- Inspect the electrical system for loose connections or damage.

Monthly maintenance

- Change the oil and oil filter.

- Change the hydraulic fluid and filter.

- Inspect the engine for any signs of wear or damage.

3. What are the safety precautions that must be taken when operating a grinder chipper machine?

- Wear appropriate safety gear, including eye protection, ear protection, and gloves.

- Never operate the machine without the hopper and discharge chute in place.

- Keep hands and feet away from the cutting blades.

- Do not overload the machine.

- Be aware of the surroundings and keep people and animals away from the machine.

4. What are the different types of materials that can be ground using a grinder chipper machine?

- Wood

- Brush

- Leaves

- Grass

- Paper

- Cardboard

5. What are the benefits of using a grinder chipper machine?

- Reduced waste volume

- Improved composting

- Reduced landfill space requirements

- Increased recycling opportunities

- Improved air quality

6. What are the different types of grinder chipper machines available?

- Electric grinder chippers

- Gas-powered grinder chippers

- Hydraulic grinder chippers

- Diesel grinder chippers

7. How do you choose the right grinder chipper machine for your needs?

- Consider the type of material you will be grinding.

- Consider the size of the material you will be grinding.

- Consider the desired output size of the ground material.

- Consider your budget.

8. What are the common problems that can occur with grinder chipper machines?

- Clogged hopper

- Dull cutting blades

- Hydraulic leaks

- Electrical problems

- Engine problems

9. How do you troubleshoot a grinder chipper machine?

- Check the hopper for clogs.

- Inspect the cutting blades for wear or damage.

- Check the hydraulic system for leaks.

- Inspect the electrical system for loose connections or damage.

- Check the engine for any signs of wear or damage.

10. What are the latest trends in grinder chipper machine technology?

- Electric grinder chippers are becoming more popular due to their reduced emissions and noise levels.

- Gas-powered grinder chippers are still the most popular type of grinder chipper due to their power and portability.

- Hydraulic grinder chippers are becoming increasingly popular for their increased power and efficiency.

- Diesel grinder chippers are the most powerful type of grinder chipper, but they are also the most expensive.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Grinder Chipper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Grinder Chipper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Grinder Chipper is responsible for operating and maintaining a grinder chipper machine. This machine is used to grind and chip wood, brush, and other organic materials. The Grinder Chipper must be able to work independently and as part of a team.

1. Operate the grinder chipper machine

The Grinder Chipper must be able to safely and efficiently operate the grinder chipper machine. This includes knowing how to start and stop the machine, how to adjust the settings, and how to troubleshoot any problems.

- Operate the grinder chipper machine in accordance with safety regulations.

- Adjust the grinder chipper machine to produce the desired output.

2. Maintain the grinder chipper machine

The Grinder Chipper must be able to maintain the grinder chipper machine in good working order. This includes cleaning the machine, lubricating the moving parts, and replacing any worn or damaged parts.

- Clean the grinder chipper machine on a regular basis.

- Lubricate the grinder chipper machine’s moving parts.

3. Inspect the grinder chipper machine

The Grinder Chipper must be able to inspect the grinder chipper machine for any damage or wear. This includes checking the belts, the blades, and the hydraulic system.

- Inspect the grinder chipper machine for any damage or wear.

- Report any damage or wear to the supervisor.

4. Troubleshooting

The Grinder Chipper must be able to troubleshoot any problems that may occur with the grinder chipper machine. This includes knowing how to identify the problem, how to fix the problem, and how to prevent the problem from happening again.

- Identify the problem with the grinder chipper machine.

- Fix the problem with the grinder chipper machine.

Interview Tips

Preparing for an interview can be a daunting task, but there are a few things you can do to increase your chances of success. Here are a few tips:

1. Research the company

Before you go on an interview, it is important to do your research on the company. This will help you understand the company’s culture, values, and goals. It will also help you answer questions about the company in a way that shows you are interested and engaged.

- Visit the company’s website.

- Read the company’s annual report.

2. Practice answering common interview questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this job?” It is important to practice answering these questions in a clear and concise way.

- Practice answering common interview questions with a friend or family member.

- Record yourself answering common interview questions and then watch the recording to see how you can improve.

3. Dress professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the job you are applying for.

- Choose clothes that are clean and pressed.

- Dress in a way that is appropriate for the job you are applying for.

4. Be on time

Punctuality is important, so make sure you arrive for your interview on time. This shows the interviewer that you are respectful of their time and that you are serious about the job.

- Plan your route to the interview in advance.

- Leave yourself plenty of time to get to the interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Grinder Chipper interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!