Feeling lost in a sea of interview questions? Landed that dream interview for Grinder Mill Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Grinder Mill Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

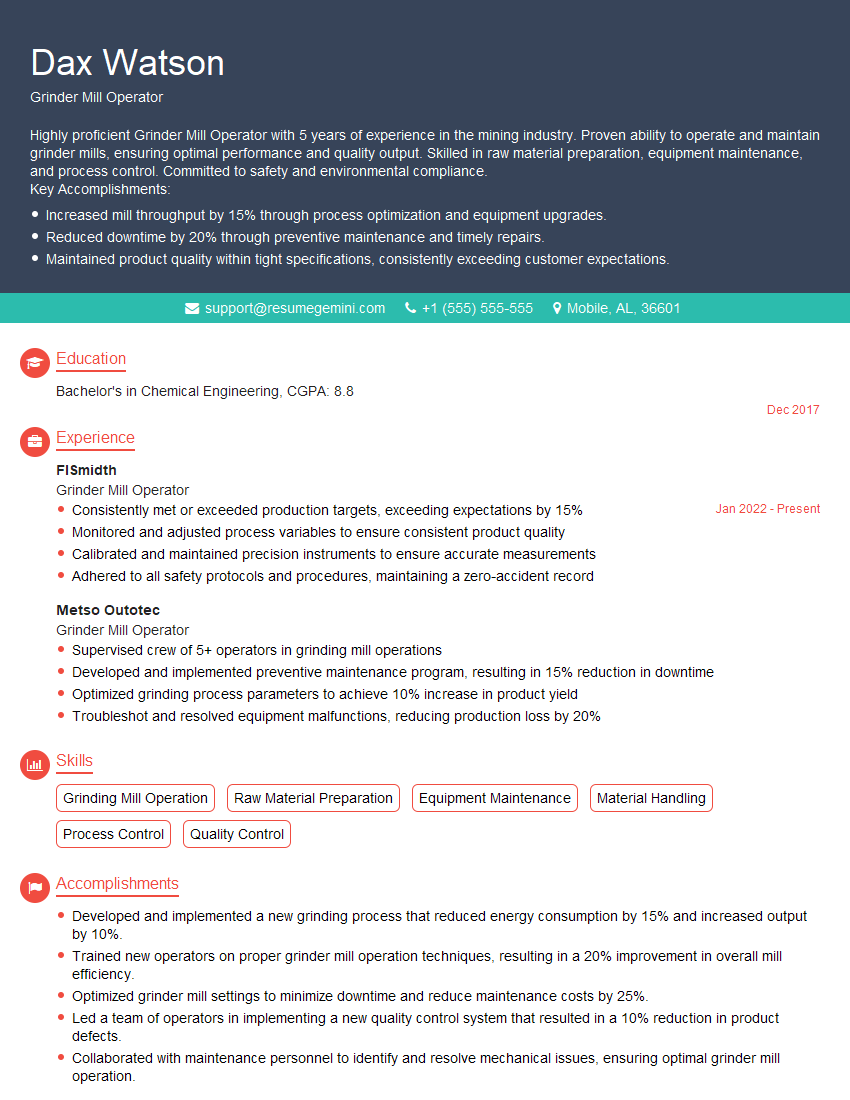

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Grinder Mill Operator

1. What is the purpose of a liner inside a grinder mill?

The liner inside a grinder mill serves multiple purposes:

- Protection: It protects the mill shell from wear and tear caused by the abrasive action of the grinding media and material.

- Size Reduction: The liners have a specific design that creates impact zones and facilitates the grinding process, helping to reduce the particle size of the material being processed.

- Heat Dissipation: The liner’s surface area helps dissipate heat generated during the grinding process, preventing overheating and maintaining optimal operating conditions.

- Noise Reduction: Liners can help absorb and dampen noise produced by the grinding process, contributing to a quieter work environment.

2. Explain the difference between open-circuit and closed-circuit grinding.

Open-Circuit Grinding

- The material is ground once and discharged directly without any classification or recirculation.

- Suitable for applications where a specific particle size is not critical or where the material is easily ground.

- Typically used in primary crushing stages or for producing coarse products.

Closed-Circuit Grinding

- The ground material is classified, and the oversized particles are recirculated to the mill for further grinding.

- Allows for precise control over the particle size distribution of the final product.

- Used in applications where a specific particle size is required or where the material is difficult to grind.

3. How do you determine the proper grinding media size and material for a specific application?

The selection of grinding media size and material depends on several factors:

- Material Hardness: Harder materials require smaller and harder grinding media to achieve the desired particle size.

- Desired Particle Size: Smaller grinding media produce finer particles, while larger media produce coarser particles.

- Mill Type and Operating Conditions: The type of mill and its operating parameters can influence the choice of media size and material.

- Cost and Availability: The availability and cost of different media materials and sizes must also be considered.

4. What are the common methods for controlling the temperature of a grinder mill?

There are several methods for controlling the temperature of a grinder mill:

- Water Cooling: Jackets or coils are used to circulate cooling water around the mill shell, reducing heat buildup.

- Air Cooling: Fans or blowers are used to circulate air around the mill, dissipating heat.

- Grinding Media: Using grinding media with a high specific heat capacity can help absorb and dissipate heat.

- Controlled Feed Rate: Adjusting the feed rate can influence the heat generated during grinding.

5. How do you maintain the proper lubrication of a grinder mill?

Proper lubrication is crucial for the smooth operation and longevity of a grinder mill:

- Regular Inspection: Conduct regular inspections to check oil levels and the condition of bearings, seals, and gears.

- Oil Changes: Replace the lubricating oil at recommended intervals to prevent contamination and maintain optimal viscosity.

- Grease Application: Apply grease to bearings and other moving components as per the manufacturer’s instructions.

- Oil Analysis: Perform oil analysis to monitor oil condition and identify any potential issues early on.

6. What are the potential causes of vibration in a grinder mill?

Vibration in a grinder mill can be caused by several factors:

- Unbalanced Grinding Media: Unevenly distributed or worn grinding media can create an imbalance, leading to vibration.

- Misalignment of Components: Misaligned gears, bearings, or shafts can cause excessive vibration.

- Mechanical Issues: Loose bolts, damaged bearings, or worn-out components can contribute to vibration.

- Resonance: The mill’s natural frequency can coincide with the operating frequency, causing excessive vibration.

7. How do you troubleshoot and resolve common problems associated with a grinder mill?

Troubleshooting common grinder mill problems requires a systematic approach:

- Identify the Symptom: Describe the specific issue or behavior observed, such as excessive vibration, low productivity, or abnormal noise.

- Gather Information: Collect data on operating parameters, maintenance history, and recent changes to the system.

- Inspect the Mill: Conduct a visual inspection to identify any visible issues or signs of wear and tear.

- Analyze the Data: Analyze the gathered information to identify potential root causes and develop a plan for corrective action.

- Resolve the Issue: Implement the necessary repairs or adjustments to address the underlying problem and restore optimal operation.

8. How do you optimize the efficiency of a grinder mill?

Optimizing grinder mill efficiency involves several key strategies:

- Proper Maintenance: Regular maintenance and inspections help prevent breakdowns and ensure optimal performance.

- Feed Rate Control: Optimizing the feed rate can improve grinding efficiency and prevent overloading.

- Grinding Media Selection: Choosing the appropriate grinding media size and material can enhance the grinding process.

- Temperature Control: Managing the temperature within the mill helps prevent overheating and maintain efficiency.

- Process Monitoring: Continuous monitoring of operating parameters allows for prompt adjustments and optimization.

9. What safety precautions should be taken when operating a grinder mill?

Operating a grinder mill requires adherence to strict safety precautions:

- Personal Protective Equipment: Wear appropriate protective gear, including earplugs, safety glasses, and gloves.

- Lockout/Tagout Procedures: Follow established procedures for isolating and de-energizing the mill before maintenance or repairs.

- Guarding: Ensure that all moving parts and access points are properly guarded to prevent contact with hazardous areas.

- Dust Control: Implement measures to minimize dust generation and exposure, such as dust collectors or ventilation systems.

- Training: Operators must receive comprehensive training on safe operating practices and emergency procedures.

10. How do you stay updated on the latest technologies and advancements in grinder mill operations?

To stay updated on the latest technologies and advancements in grinder mill operations:

- Industry Conferences and Trade Shows: Attend industry events to learn about new equipment, technologies, and best practices.

- Technical Publications and Journals: Read industry publications and research papers to stay informed about innovations.

- Manufacturers’ Websites: Visit websites of grinder mill manufacturers to access technical resources and information on new products.

- Networking and Collaboration: Connect with other professionals in the field to exchange knowledge and learn about industry trends.

- Continuing Education: Participate in workshops, seminars, or online courses to enhance your skills and knowledge.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Grinder Mill Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Grinder Mill Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Grinder Mill Operators play a crucial role in the manufacturing process by operating and maintaining grinder mills. They are responsible for ensuring the efficient and safe production of materials such as cement, minerals, and chemicals.

1. Operating and Maintaining Grinder Mills

Grinder Mill Operators are responsible for operating and maintaining grinder mills, which are used to reduce the size of materials. They must be able to adjust the settings of the mill to achieve the desired particle size.

- Inspecting and maintaining grinder mills to ensure their proper functioning

- Adjusting the settings of the mill to achieve the desired particle size

- Ensuring that the mill is operated in a safe and efficient manner

2. Material Handling

Grinder Mill Operators are also responsible for handling the materials that are being ground. They must be able to safely load and unload materials from the mill.

- Loading and unloading materials from the mill

- Ensuring that the materials are handled in a safe and efficient manner

3. Quality Control

Grinder Mill Operators must be able to ensure the quality of the materials that are being produced by the mill. They must be able to identify and correct any problems that may arise.

- Inspecting the materials produced by the mill to ensure their quality

- Correcting any problems that may arise

4. Safety

Grinder Mill Operators must be able to follow all safety procedures and regulations. They must also be able to identify and mitigate potential hazards.

- Following all safety procedures and regulations

- Identifying and mitigating potential hazards

Interview Tips

Preparing for a Grinder Mill Operator interview can be daunting, but with the right strategies, you can increase your chances of success. Here are some tips to help you ace your interview:

1. Research the Company and Position

Before you go to your interview, take some time to research the company and the position you are applying for. This will help you better understand the company’s culture and values, as well as the specific requirements of the role.

- Visit the company’s website

- Read articles about the company and the industry

- Identify the key skills and qualifications required for the position

2. Practice Your Answers to Common Interview Questions

There are some common interview questions that you are likely to be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”. It is important to practice your answers to these questions in advance so that you can deliver them confidently and clearly.

- Prepare your answers to common interview questions

- Practice your answers out loud

- Have a friend or family member ask you interview questions

3. Be Prepared to Talk About Your Experience

In your interview, you will be asked about your experience and qualifications. Be prepared to talk about your skills and experience as they relate to the position you are applying for. You should also be able to provide examples of your work.

- Highlight your skills and experience in your resume and cover letter

- Be prepared to talk about your experience in detail

- Provide examples of your work that demonstrate your skills

4. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally for your interview. You should also arrive on time for your interview. This shows the interviewer that you are respectful of their time.

- Dress professionally for your interview

- Arrive on time for your interview

- Be polite and respectful to the interviewer

5. Follow Up After the Interview

After your interview, it is important to follow up with the interviewer. This shows that you are interested in the position and that you are eager to learn more about the company. You can send a thank-you note or email to the interviewer, or you can call to check on the status of your application.

- Send a thank-you note or email to the interviewer

- Call to check on the status of your application

- Be patient and persistent

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Grinder Mill Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!