Feeling lost in a sea of interview questions? Landed that dream interview for Grinder Operator, Surface, Tool but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Grinder Operator, Surface, Tool interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

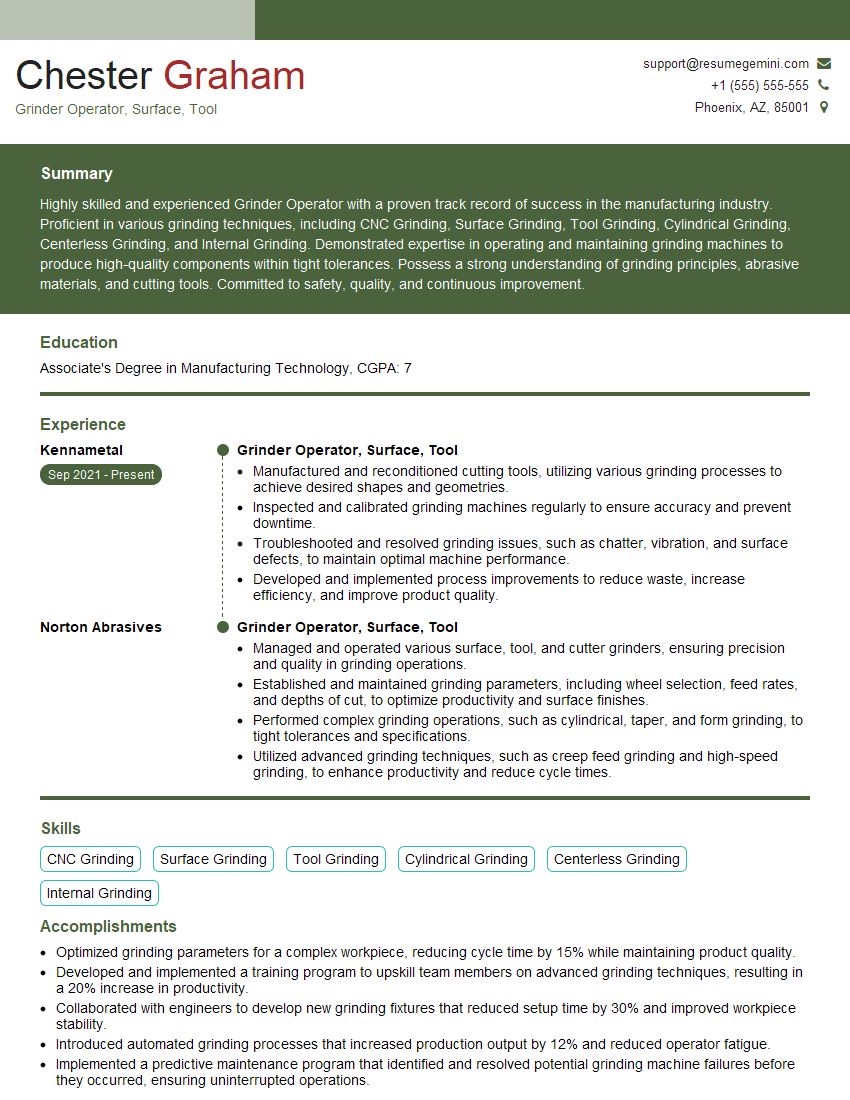

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Grinder Operator, Surface, Tool

1. What is the difference between surface grinding and tool grinding?

Surface grinding involves removing material from a workpiece’s surface to achieve a desired finish, tolerance, or shape. In contrast, tool grinding focuses on sharpening and reshaping cutting tools, such as drill bits, milling cutters, and lathe tools, to ensure optimal performance and longevity.

2. Explain the different types of grinding wheels and their applications.

Grinding wheels are classified based on their abrasive material, bond type, and grain size. Common types include:

- Abrasive Material: Aluminum oxide, silicon carbide, cubic boron nitride

- Bond Type: Vitrified, resinoid, metal, ceramic

- Grain Size: Coarse, medium, fine, superfine

Wheel selection depends on the material being ground, the desired finish, and the grinding operation.

3. Describe the coolant systems used in grinding operations.

- Flood Coolant: A large volume of coolant is directed at the grinding zone to remove chips, lubricate, and cool the workpiece.

- Mist Coolant: A fine mist of coolant is sprayed onto the grinding zone, providing lubrication and reducing heat generation.

- Compressed Air: Used in conjunction with a coolant or as a standalone method to remove chips and prevent workpiece overheating.

4. How do you calculate the grinding wheel speed and feed rate?

Grind speed (Vs) and feed rate (Fr) are determined based on various factors:

- Workpiece Material: Harder materials require higher speeds and lower feeds.

- Wheel Type: The bond type and abrasive material influence the recommended speed range.

- Desired Finish: Finer finishes require lower speeds and higher feeds.

Specific formulas and tables are available to calculate these parameters based on the given criteria.

5. Discuss the importance of maintaining proper wheel balance and truing.

- Wheel Balance: Prevents vibration and ensures smooth grinding, reducing defects and improving surface finish.

- Wheel Truing: Restores the wheel’s cylindrical shape, ensuring accurate grinding and preventing uneven wear or damage.

6. Explain the process of loading a workpiece onto a magnetic chuck.

- Clean the chuck and workpiece surfaces to ensure proper magnetic contact.

- Position the workpiece on the chuck, ensuring it is securely held.

- Activate the magnetic field to hold the workpiece firmly in place.

- Check the workpiece alignment and make any necessary adjustments.

7. Describe the safety precautions to be observed when operating a grinding machine.

- Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and earplugs.

- Ensure the machine is properly grounded and all guards are in place.

- Use the correct grinding wheel for the job and follow recommended speeds and feeds.

- Be aware of the workpiece rotation direction and keep hands clear of the grinding zone.

- Never leave the machine unattended while it is running.

8. Discuss the different types of surface grinders.

- Horizontal Spindle Surface Grinder: Workpiece is held on a reciprocating table that moves in the X-Y plane.

- Vertical Spindle Surface Grinder: Workpiece is held stationary on a table while the grinding wheel moves in the Z-axis.

- CNC Surface Grinder: Computer-controlled machine that provides precise grinding operations.

9. Explain the process of grinding a flat surface on a surface grinder.

- Mount the workpiece securely on the magnetic chuck.

- Set the grinding wheel speed and feed rate.

- Engage the coolant system to remove chips and lubricate.

- Move the table in a reciprocating motion while the grinding wheel traverses the workpiece surface.

- Monitor the grinding progress and make adjustments as needed to achieve the desired finish.

10. Discuss the factors that affect the accuracy of a ground surface.

- Wheel condition and truing

- Workpiece material and hardness

- Machine rigidity and alignment

- Environmental conditions (temperature, humidity)

- Operator skill and experience

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Grinder Operator, Surface, Tool.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Grinder Operator, Surface, Tool‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Grinder Operator, Surface, Tool, you will have the primary responsibilities of operating grinding machines to shape and finish metal surfaces and tools. Your duties will encompass a range of tasks, including:

1. Machine Operation

You will be responsible for operating and maintaining a variety of grinding machines, such as surface grinders, tool grinders, and cylindrical grinders.

- Set up and adjust machines according to specifications and blueprints.

- Monitor grinding processes and make adjustments to ensure accurate and consistent results.

- Use precision measuring instruments to inspect and verify the dimensions and quality of finished products.

2. Workpiece Preparation

Prior to grinding, you will prepare workpieces by:

- Cleaning and preparing surfaces to ensure proper adhesion.

- Selecting and installing appropriate grinding wheels.

- Determining and setting the optimal grinding parameters (speed, feed, and depth).

3. Quality Control

You will be responsible for ensuring the quality of finished products by:

- Inspecting workpieces for defects, such as cracks, burrs, and imperfections.

- Using gauges and other testing equipment to verify dimensional accuracy and surface finish.

- Following established quality control procedures and reporting any non-conformances.

4. Tool Maintenance

You will perform regular maintenance and repairs on grinding machines and associated equipment to ensure optimal performance and minimize downtime.

- Clean and lubricate machines as per manufacturer’s instructions.

- Replace worn or damaged components, such as grinding wheels, belts, and bearings.

- Troubleshoot and resolve machine malfunctions to maintain production efficiency.

Interview Tips

To ace your interview for the Grinder Operator, Surface, Tool position, consider the following tips:

1. Research the Company and Position

Familiarize yourself with the company’s industry, products/services, and the specific role you’re applying for. Researching the company will demonstrate your interest and enable you to ask informed questions.

2. Highlight Relevant Skills and Experience

Emphasize your proficiency in operating grinding machines, your knowledge of grinding techniques, and your experience with quality control procedures. Quantify your accomplishments and provide specific examples to showcase your abilities.

3. Practice Common Interview Questions

Prepare for common interview questions by practicing your responses. Anticipate questions about your experience, skills, knowledge of grinding processes, and your approach to quality control. Consider using the STAR method (Situation, Task, Action, Result) to structure your answers.

4. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of an interview shows your engagement and interest. Prepare questions that demonstrate your curiosity about the company, the position, and the industry.

5. Dress Professionally and Arrive on Time

First impressions matter. Dress appropriately for the interview and arrive on time. A professional demeanor and punctuality convey respect for the interviewer and the position you’re seeking.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Grinder Operator, Surface, Tool interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!