Feeling lost in a sea of interview questions? Landed that dream interview for Grinding Wheel Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Grinding Wheel Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

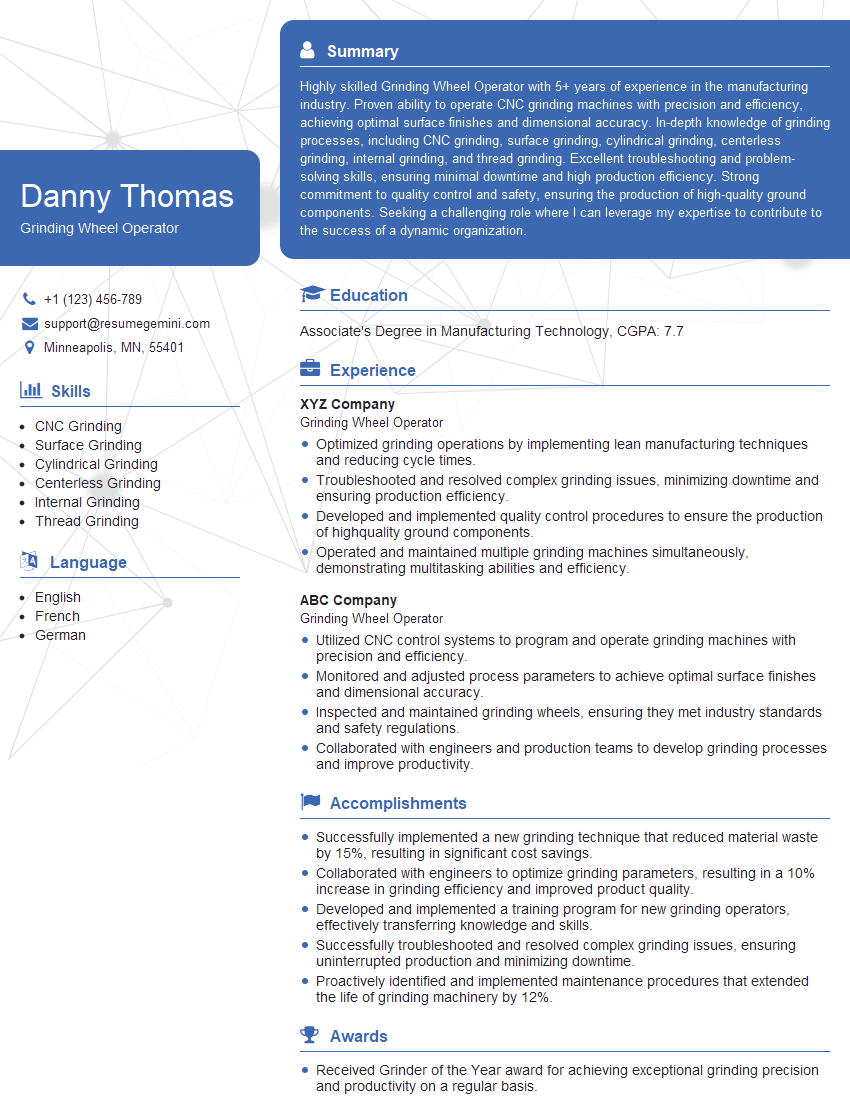

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Grinding Wheel Operator

1. Explain the process of selecting the correct grinding wheel for a specific application?

When selecting a grinding wheel, I consider the following factors:

- Material to be ground

- Desired surface finish

- Type of grinding operation

- Speed and feed rate

- Wheel size and shape

- Bond type and grit size

2. How do you ensure that the grinding wheel is properly mounted and balanced?

Mounting the Grinding Wheel

- Inspect the wheel for any damage or defects.

- Clean the wheel mounting surface and the wheel flange.

- Place the wheel on the flange and secure it with the nut or bolts.

- Tighten the nut or bolts evenly and to the manufacturer’s specifications.

Balancing the Grinding Wheel

- Mount the wheel on a balancing machine.

- Start the machine and allow it to reach the desired speed.

- Observe the wheel for any vibration or wobble.

- If the wheel is out of balance, add or remove weight to the appropriate side of the wheel until it is balanced.

3. What are the different types of grinding wheels and their applications?

The main types of grinding wheels are:

- Cylindrical grinding wheels: Used for grinding cylindrical surfaces, such as shafts and pins.

- Surface grinding wheels: Used for grinding flat surfaces, such as on machine tables and tool bits.

- Centerless grinding wheels: Used for grinding round parts, such as ball bearings and rollers.

- Internal grinding wheels: Used for grinding the inside of holes and other internal surfaces.

- Cut-off grinding wheels: Used for cutting through materials, such as metal pipe and rebar.

4. Discuss the safety precautions that must be followed when operating a grinding wheel?

- Wear appropriate safety gear, including eye protection, gloves, and a respirator.

- Ensure that the grinding wheel is properly mounted and balanced.

- Never operate a grinding wheel that is damaged or defective.

- Keep the work area clean and free of debris.

- Be aware of the sparks and hot metal chips that are produced during grinding.

- Follow all manufacturer’s instructions for the safe operation of the grinding wheel.

5. How do you troubleshoot common grinding wheel problems, such as wheel glazing, loading, and sparking?

Wheel Glazing

- Caused by the build-up of material on the wheel surface.

- Solved by dressing the wheel with a diamond dresser or by using a softer wheel.

Wheel Loading

- Caused by the build-up of material in the wheel pores.

- Solved by using a harder wheel or by increasing the wheel speed.

Sparking

- Caused by the wheel rubbing against the workpiece.

- Solved by increasing the wheel speed or by using a softer wheel.

6. Explain the different types of grinding fluids and their applications?

The main types of grinding fluids are:

- Water-soluble fluids: Used for general-purpose grinding operations.

- Oil-based fluids: Used for heavy-duty grinding operations and for grinding materials that are difficult to wet.

- Synthetic fluids: Used for high-performance grinding operations and for grinding materials that are sensitive to corrosion.

7. How do you measure and control the temperature of the grinding zone?

- Use a thermocouple or infrared thermometer to measure the temperature of the grinding zone.

- Control the temperature by adjusting the grinding speed, feed rate, and coolant flow rate.

- Monitor the temperature closely to prevent overheating, which can damage the wheel and the workpiece.

8. Describe the different methods of dressing and truing a grinding wheel?

Dressing

- Used to remove the build-up of material on the wheel surface.

- Can be done manually with a diamond dresser or automatically with a dressing attachment.

Truing

- Used to correct the shape of the grinding wheel.

- Can be done manually with a truing diamond or automatically with a truing attachment.

9. How do you maintain and store grinding wheels?

- Store grinding wheels in a dry, clean place.

- Inspect grinding wheels regularly for any damage or defects.

- Dress and true grinding wheels as needed.

- Follow all manufacturer’s instructions for the maintenance and storage of grinding wheels.

10. What are the latest advancements in grinding wheel technology?

- Superabrasive grinding wheels: Made with synthetic diamonds or cubic boron nitride, these wheels can grind very hard materials.

- Electroplated grinding wheels: The abrasive grains are electroplated onto the wheel surface, providing a longer lifespan.

- Automated grinding machines: These machines use computer-controlled technology to optimize the grinding process.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Grinding Wheel Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Grinding Wheel Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Grinding Wheel Operators play a critical role in various industries, operating grinding machines to reshape, sharpen, and polish metal workpieces. Their expertise in handling abrasive grinding wheels ensures precise and efficient material removal.

1. Grinding Operations

Execute grinding operations based on specified blueprints and instructions.

- Select and install appropriate grinding wheels.

- Adjust and operate grinding machines, maintaining proper feed rates and speeds.

2. Workpiece Preparation and Measurement

Prepare workpieces, ensuring they are properly secured and aligned.

- Read and interpret technical drawings.

- Measure and inspect workpieces, using precision measuring tools.

3. Quality Assurance

Maintain high standards of quality and accuracy.

- Continuously monitor grinding operations, identifying and correcting deviations.

- Follow established quality control procedures, ensuring compliance with specifications.

4. Machine Maintenance and Troubleshooting

Perform routine maintenance and troubleshooting to ensure optimal machine performance.

- Clean, lubricate, and adjust grinding machines.

- Identify and resolve minor malfunctions, following established protocols.

Interview Tips

Preparing thoroughly for a Grinding Wheel Operator interview can significantly boost your chances of success. Here are some valuable tips to help you ace the interview:

1. Research the Company and Position

Familiarize yourself with the company’s background, industry, and products/services. Understand the specific requirements of the Grinding Wheel Operator position and align your skills and experience accordingly.

- Visit the company’s website and LinkedIn page.

- Read industry publications and articles.

2. Practice Your Answers

Prepare thoughtful responses to common interview questions related to your skills, experience, and motivations. Practice your answers aloud to build confidence and ensure clarity.

- Describe your experience in operating grinding machines.

- Explain how you maintain quality standards in your work.

3. Highlight Your Technical Skills

Emphasize your expertise in grinding operations, including your knowledge of different grinding wheels, speeds, and feeds. Showcase your proficiency in using precision measuring tools and interpreting technical drawings.

- Discuss your experience in selecting and installing grinding wheels.

- Describe your understanding of grinding parameters and their impact on workpiece quality.

4. Demonstrate Your Problem-Solving Abilities

Interviewers often assess candidates’ problem-solving skills. Provide examples of how you have identified and resolved issues related to grinding operations or machine functionality.

- Share an experience where you identified a problem with a grinding machine and implemented a solution.

- Describe how you troubleshoot and resolve common grinding issues.

5. Ask Informed Questions

Asking thoughtful questions at the end of the interview shows your interest and engagement. Prepare questions about the company’s grinding operations, industry trends, or the specific role and responsibilities.

- Ask about the company’s approach to quality control.

- Inquire about opportunities for professional development and advancement.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Grinding Wheel Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!