Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Grip Wrapper position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

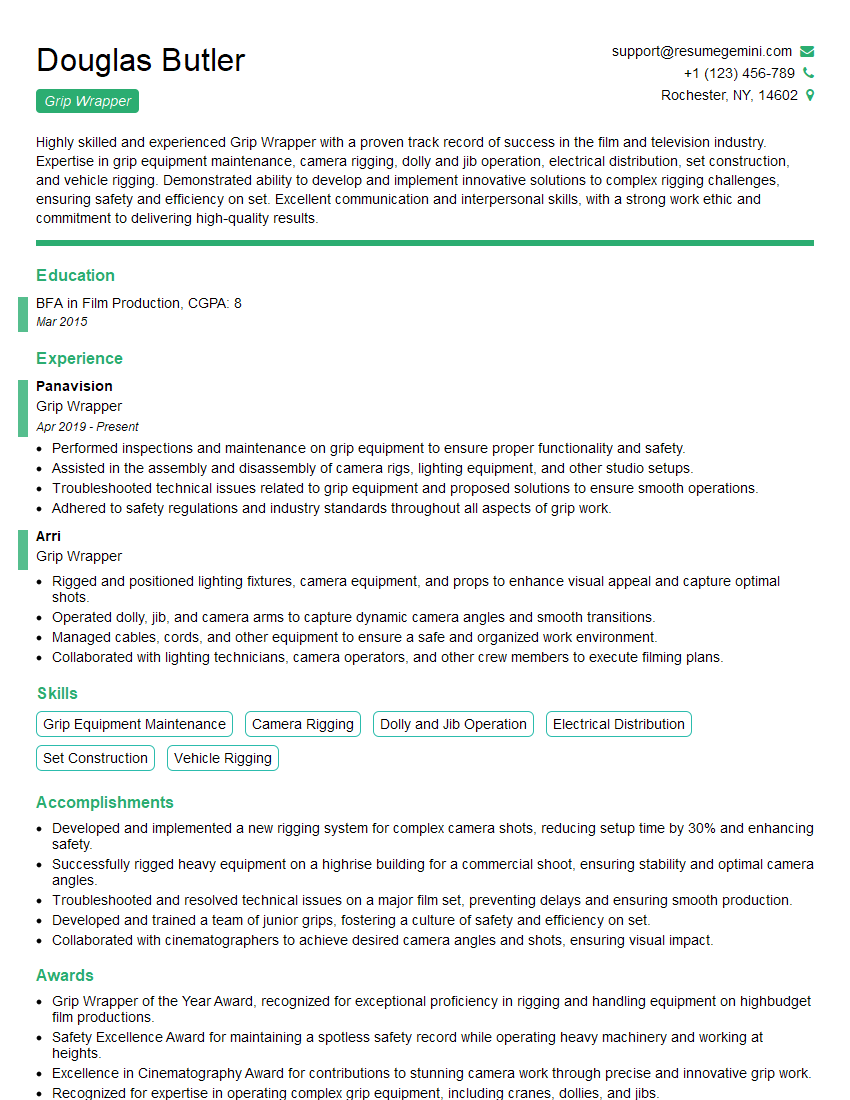

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Grip Wrapper

1. What is the difference between a shrink wrap and a stretch wrap?

Shrink wrap and stretch wrap are both types of plastic film used to protect and stabilize products during storage and transportation. However, there are some key differences between the two types of film:

- Shrink wrap is made from a type of plastic that shrinks when heated, conforming to the shape of the product it is wrapped around. This makes it ideal for wrapping products that need to be protected from moisture, dust, and other environmental factors.

- Stretch wrap, on the other hand, is made from a type of plastic that can be stretched to several times its original length. This makes it ideal for wrapping products that need to be protected from damage during shipping or handling.

2. What are the different types of shrink wrap machines?

Semi-automatic machines

- Semi-automatic shrink wrap machines require an operator to load and unload the products to be wrapped. The machine then automatically applies the shrink wrap and shrinks it to the desired size.

Fully-automatic machines

- Fully-automatic shrink wrap machines do not require an operator to load or unload the products. The machine automatically feeds the products into the wrapping area, applies the shrink wrap, and shrinks it to the desired size.

Manual machines

- Manual shrink wrap machines are the most basic type of shrink wrap machine. They require the operator to manually apply the shrink wrap to the product and then shrink it using a heat gun.

3. What are the different types of stretch wrap films?

- Cast stretch wrap film is made by extruding molten plastic through a die to create a thin film. Cast stretch wrap film is strong and durable, but it is also more expensive than blown stretch wrap film.

- Blown stretch wrap film is made by blowing molten plastic through a die to create a thin film. Blown stretch wrap film is less expensive than cast stretch wrap film, but it is also less strong and durable.

4. What are the benefits of using shrink wrap or stretch wrap?

- Protects products from damage – Shrink wrap and stretch wrap can help to protect products from damage during shipping and handling by providing a barrier against moisture, dust, and other environmental factors.

- Improves product stability – Shrink wrap and stretch wrap can help to improve product stability by bundling products together and preventing them from shifting during transit.

- Reduces shipping costs – Shrink wrap and stretch wrap can help to reduce shipping costs by reducing the amount of packaging material required and by making products easier to handle.

5. What are the safety precautions that should be taken when using shrink wrap or stretch wrap?

- Use caution when using heat guns – Heat guns can reach high temperatures and can cause burns if not used properly. Always wear gloves and eye protection when using a heat gun.

- Do not use shrink wrap or stretch wrap in enclosed areas – Shrink wrap and stretch wrap can release harmful fumes when heated. Always use shrink wrap and stretch wrap in well-ventilated areas.

- Keep shrink wrap and stretch wrap away from children and pets – Shrink wrap and stretch wrap can be a choking hazard if ingested. Always keep shrink wrap and stretch wrap out of reach of children and pets.

6. What are the different techniques for shrink wrapping?

- Manual shrink wrapping – Manual shrink wrapping is the most basic technique and requires the use of a heat gun to shrink the wrap around the product.

- Semi-automatic shrink wrapping – Semi-automatic shrink wrapping machines use a combination of manual and automatic processes to shrink wrap products.

- Fully-automatic shrink wrapping – Fully-automatic shrink wrapping machines automate the entire shrink wrapping process.

7. What are the different techniques for stretch wrapping?

- Manual stretch wrapping – Manual stretch wrapping is the most basic technique and requires the use of a handheld stretch wrap dispenser to apply the wrap around the product.

- Machine stretch wrapping – Machine stretch wrapping machines use a combination of manual and automatic processes to stretch wrap products.

- Robotic stretch wrapping – Robotic stretch wrapping machines automate the entire stretch wrapping process.

8. What are the common problems that can occur when using shrink wrap or stretch wrap?

- Tearing – Shrink wrap and stretch wrap can tear if it is not applied properly or if the product is too sharp.

- Wrinkling – Shrink wrap and stretch wrap can wrinkle if it is not applied smoothly.

- Punctures – Shrink wrap and stretch wrap can be punctured by sharp objects.

9. How can you troubleshoot problems with shrink wrap or stretch wrap?

- Tearing – If shrink wrap or stretch wrap is tearing, try using a thicker gauge of film or applying the wrap more carefully.

- Wrinkling – If shrink wrap or stretch wrap is wrinkling, try applying the wrap more smoothly or using a heat gun to shrink the wrap more evenly.

- Punctures – If shrink wrap or stretch wrap is punctured, try using a patch or applying a thicker gauge of film.

10. What are the latest trends in shrink wrap and stretch wrap technology?

- Sustainable shrink wrap and stretch wrap – There is a growing demand for sustainable shrink wrap and stretch wrap products that are made from recycled materials or that are biodegradable.

- Automated shrink wrap and stretch wrap machines – Automated shrink wrap and stretch wrap machines are becoming increasingly popular as they can help to improve efficiency and reduce labor costs.

- Smart shrink wrap and stretch wrap – Smart shrink wrap and stretch wrap products are being developed that can track the location of products and provide other data.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Grip Wrapper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Grip Wrapper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Grip Wrappers are responsible for the safe and efficient handling of equipment on film sets and in studios. They work closely with directors and other production crew to ensure that all equipment is in place and ready to use.

1. Setup and Operation

Grip Wrappers set up and operate a variety of equipment, including cameras, lighting, and sound equipment.

- Assemble and disassemble equipment according to specifications.

- Operate equipment safely and efficiently.

2. Equipment Maintenance

Grip Wrappers are responsible for maintaining all equipment in good working order.

- Inspect equipment regularly for damage.

- Clean and lubricate equipment as needed.

3. Safety

Grip Wrappers are responsible for ensuring the safety of all cast and crew on set.

- Follow all safety regulations.

- Identify and mitigate potential hazards.

4. Communication

Grip Wrappers must be able to communicate effectively with directors, other crewmembers, and cast.

- Follow instructions clearly and concisely.

- Communicate changes or problems effectively.

Interview Tips

Preparing for an interview for a Grip Wrapper position can be daunting, but with the right tips and strategies, you can increase your chances of success.

1. Research the Company

Before your interview, take some time to research the company you’re applying to. This will help you understand their culture, values, and what they’re looking for in a Grip Wrapper.

- Visit the company’s website.

- Read their social media pages.

2. Practice Your Answers

Once you have a good understanding of the company, you can start practicing your answers to common interview questions. This will help you feel more confident and prepared during the interview.

- Use the STAR method to answer questions.

- Tailor your answers to the specific job you’re applying for.

3. Bring Relevant Materials

In addition to your resume and portfolio, you may want to bring other relevant materials to your interview, such as:

- References

- Letters of recommendation

- Samples of your work

4. Dress Professionally

First impressions matter, so it’s important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the job you’re applying for.

- Avoid wearing jeans, t-shirts, or shorts.

- Choose clothes that are comfortable and allow you to move around easily.

5. Be Yourself

The most important thing is to be yourself during your interview. Don’t try to be someone you’re not, because the interviewer will be able to tell.

- Answer questions honestly and thoughtfully.

- Be enthusiastic and passionate about the job.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Grip Wrapper interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!