Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Gritting Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Gritting Machine Operator so you can tailor your answers to impress potential employers.

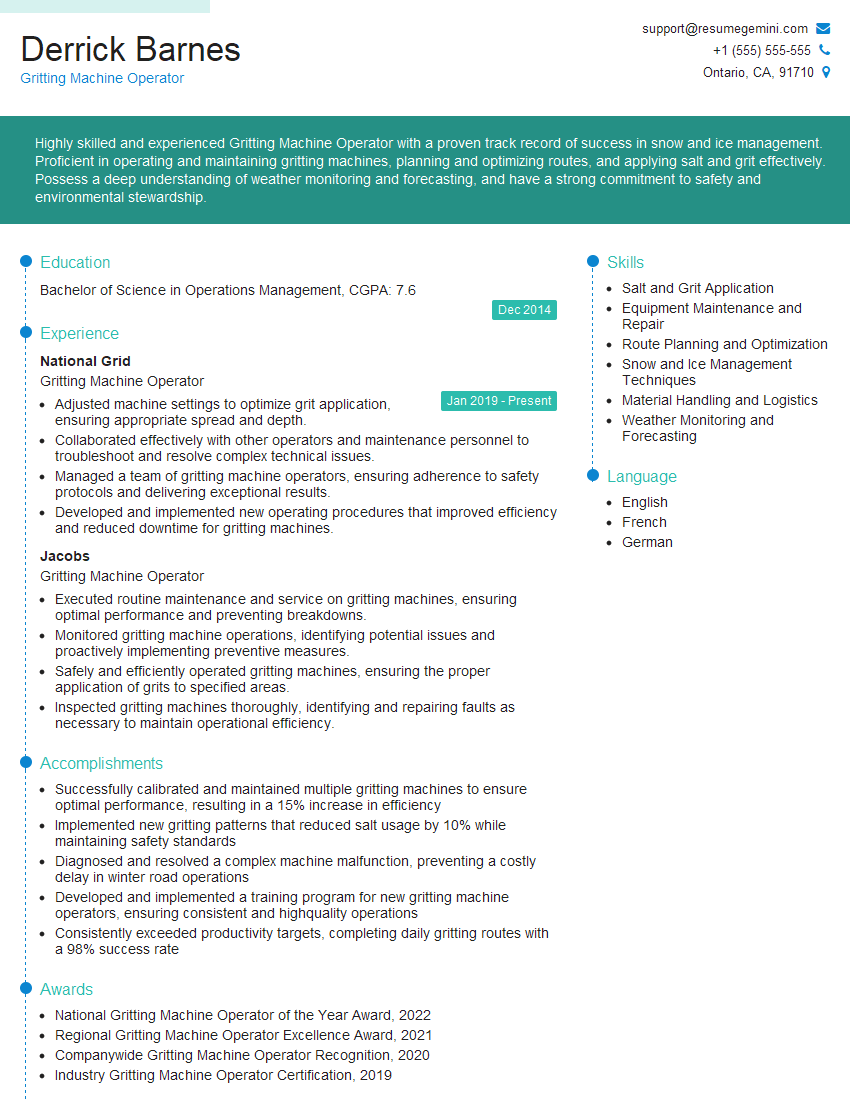

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Gritting Machine Operator

1. What are the key responsibilities of a Gritting Machine Operator?

As a Gritting Machine Operator, my key responsibilities include:

- Operating gritting machines to apply salt or grit to roads and pavements during winter months to prevent ice formation and ensure safe driving conditions.

- Monitoring gritting operations to ensure even distribution and proper application rates.

- Inspecting and maintaining gritting equipment, including vehicles, spreaders, and attachments.

- Loading and unloading grit from storage facilities and ensuring adequate supplies.

- Collaborating with other team members and supervisors to plan and execute gritting operations.

2. Describe the different types of gritting machines and their applications.

There are several types of gritting machines used for various applications, including:

a. Truck-Mounted Gritters:

- Mounted on trucks, these machines are used for large-scale gritting operations on major roads and highways.

- Equipped with large spreaders and storage capacity, they can cover extensive areas efficiently.

b. Tractor-Mounted Gritters:

- Attached to tractors, these machines are ideal for smaller areas such as residential streets and car parks.

- More maneuverable than truck-mounted gritters, they can access narrow or congested areas.

c. Pedestrian-Controlled Gritters:

- Manually operated by a single person, these machines are used for sidewalks, footpaths, and other pedestrian areas.

- Lightweight and easy to use, they provide precise gritting in targeted locations.

3. What are the factors that determine the gritting rate and application method?

The gritting rate and application method are determined by several factors, including:

- Weather conditions (e.g., temperature, precipitation, wind speed)

- Road surface conditions (e.g., wet, icy, snowy)

- Traffic volume and speed limits

- Environmental regulations and guidelines

- Type of gritting machine being used

4. Explain the importance of calibrating gritting machines.

Calibration of gritting machines is crucial for ensuring accurate and efficient gritting operations:

- It ensures that the correct amount of grit is applied to the road surface.

- Helps prevent over- or under-application, which can be wasteful or ineffective.

- Optimizes the distribution of grit, reducing the risk of uneven surfaces or icy patches.

- Improves safety by ensuring that roads are adequately treated to prevent accidents.

5. Describe the safety procedures that must be followed when operating gritting machines.

When operating gritting machines, it is essential to prioritize safety by adhering to the following procedures:

- Wearing appropriate personal protective equipment (PPE), including high-visibility clothing, gloves, and eye protection.

- Conducting thorough pre-operation checks of the machine to ensure it is in good working order.

- Following designated gritting routes and adhering to traffic regulations.

- Maintaining a safe distance from other vehicles and pedestrians.

- Being aware of weather conditions and adjusting operations accordingly.

- Reporting any accidents, incidents, or near-misses immediately.

6. How do you handle situations where gritting operations are disrupted due to mechanical issues or adverse weather conditions?

In the event of mechanical issues or adverse weather conditions that disrupt gritting operations, I typically follow these steps:

- Assess the situation and identify the cause of the disruption.

- Attempt to resolve minor issues myself if possible, such as clearing blockages or adjusting settings.

- Contact a supervisor or mechanic for assistance with more complex issues.

- If weather conditions make gritting unsafe or ineffective, I will suspend operations and report the situation.

- Stay informed about weather forecasts and adjust operations as necessary to ensure public safety.

7. What are the best practices for maintaining gritting machines and ensuring their optimal performance?

To maintain gritting machines and ensure their optimal performance, I follow these best practices:

- Regularly cleaning and inspecting the machine, including the spreader, conveyor, and hydraulic systems.

- Lubricating and servicing the machine according to manufacturer’s recommendations.

- Storing the machine in a dry and protected environment when not in use.

- Conducting seasonal inspections and maintenance before and after gritting operations.

- Keeping a maintenance log to track inspections, repairs, and service history.

8. How do you stay up-to-date with the latest industry best practices and technological advancements in gritting operations?

I stay up-to-date with industry best practices and technological advancements in gritting operations by:

- Attending industry conferences and workshops.

- Reading trade publications and online resources.

- Consulting with manufacturers and suppliers for the latest equipment and techniques.

- Networking with other gritting professionals to share knowledge and experiences.

- Participating in training programs to enhance my skills and stay abreast of new developments.

9. How do you prioritize tasks and manage your workload during busy gritting seasons?

During busy gritting seasons, I prioritize tasks and manage my workload effectively by:

- Creating a daily or weekly schedule to plan my operations.

- Identifying and prioritizing high-priority areas based on traffic volume and weather conditions.

- Delegating tasks to other team members when necessary.

- Communicating with supervisors and colleagues to coordinate efforts.

- Taking breaks and managing my time wisely to avoid burnout.

10. Describe a challenging situation you faced as a Gritting Machine Operator and how you overcame it.

One challenging situation I faced was during a particularly heavy snowfall. The roads were treacherous, and visibility was poor. To ensure public safety, I decided to extend my gritting route to include additional side streets and pedestrian areas. However, the increased workload put a strain on my machine. I encountered mechanical issues that required me to make quick repairs on the spot. By using my problem-solving skills and the tools available on my truck, I fixed the issues and completed the gritting operations. This experience taught me the importance of being adaptable and resourceful in challenging situations.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Gritting Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Gritting Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Gritting Machine Operators are responsible for safely and efficiently operating gritting machines to spread salt or other de-icing materials on roads and other surfaces during winter weather conditions. They play a crucial role in maintaining road safety and minimizing accidents during slippery conditions.

1. Operate Gritting Machine

The primary responsibility of a Gritting Machine Operator is to operate the gritting machine safely and efficiently. This involves:

- Monitoring the machine’s controls and systems during operation

- Adjusting the grit spreading rate and pattern based on road conditions

- Ensuring the machine is properly calibrated and maintained for optimal performance

- Loading, unloading, and weighing of grit materials and maintaining adequate supplies

2. Monitor Road Conditions

Operators are responsible for monitoring road conditions to determine areas that require treatment. This includes:

- Observing weather conditions and forecasts

- Identifying hazardous areas, such as black ice, snow drifts, and slippery surfaces

- Coordinating with other operators and traffic control personnel to ensure efficient coverage of treated areas

3. Safety and Compliance

Gritting Machine Operators are committed to safety and compliance regulations. They:

- Adhere to established routes, schedules, and spreading patterns

- Wear appropriate personal protective equipment and follow safety protocols

- Monitor weather and road conditions to ensure safe operating environments

- Report any accidents or incidents promptly

4. Maintenance and Troubleshooting

Operators are responsible for basic maintenance and troubleshooting of the gritting machines. They:

- Conduct daily inspections and routine maintenance checks

- Identify and resolve minor mechanical issues

- Report any major maintenance needs or repairs to supervisors promptly

Interview Tips

Preparing for an interview as a Gritting Machine Operator requires careful consideration. Here are some valuable tips to help you ace the interview:

1. Research the Company and Role

Take the time to thoroughly research the company you are applying to and the specific role of Gritting Machine Operator. This will help you understand their business, values, and the expectations for the position.

- Visit the company website to learn about their mission, history, and services.

- Read industry news and articles to stay informed about the latest developments in winter maintenance.

2. Highlight Relevant Experience and Skills

Emphasize your experience and skills that are relevant to the role. If you have previous experience operating gritting machines or similar equipment, be sure to highlight it in your resume and during the interview.

- Quantify your accomplishments whenever possible.

- Use action verbs and specific examples to describe your responsibilities.

3. Demonstrate Knowledge of Safety Procedures

Safety is paramount in this role. Show the interviewer that you are aware of and committed to following all safety procedures and regulations. Explain how you prioritize safety in your work and provide examples of how you have done so in the past.

- Be prepared to discuss your understanding of relevant safety protocols and guidelines.

- Highlight any certifications or training you have related to safety.

4. Prepare for Common Interview Questions

Research common interview questions for Gritting Machine Operators. Practice answering these questions thoughtfully and concisely. Some common questions include:

- Why are you interested in this role?

- Tell me about your experience operating gritting machines.

- How do you ensure safety while operating heavy machinery?

- Describe a time when you had to troubleshoot a problem with a gritting machine.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Gritting Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.