Are you gearing up for an interview for a Grommet Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Grommet Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

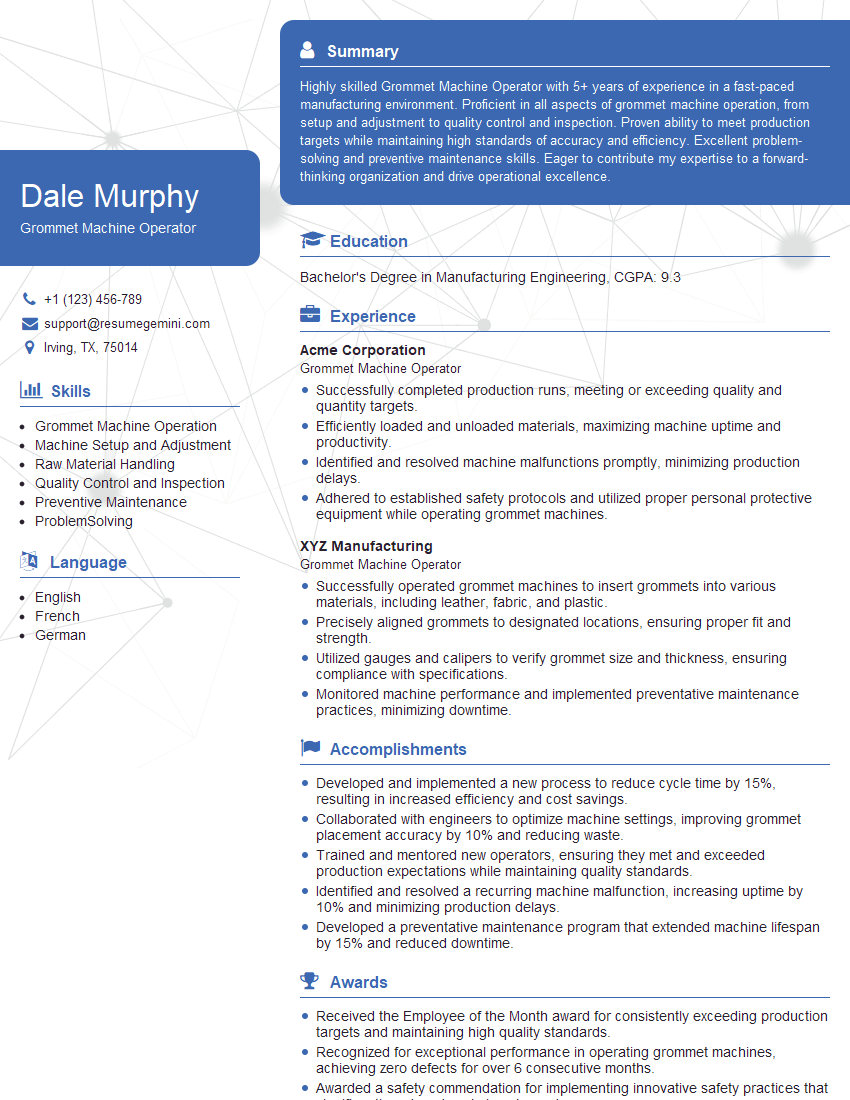

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Grommet Machine Operator

1. What are the different types of grommets?

There are various types of grommets, each designed for specific applications and materials. Some common types of grommets include:

- Eyelets: These are simple, unlined grommets that are used to reinforce holes and prevent tearing, such as in canvas or banners.

- Washers: These are flat, unlined grommets that are used to distribute the load of a screw or bolt, preventing the material from deforming.

- Flange grommets: These are grommets with a wide flange or lip that provides additional support and prevents the grommet from pulling through the material.

- Insulating grommets: These grommets are made of non-conductive materials and are used to isolate electrical wires and cables.

- Self-clinching grommets: These grommets have sharp teeth or prongs that pierce the material and create a tight, secure hold without the need for additional tools or fasteners.

2. What factors should be considered when selecting the right grommet?

Material Thickness

- Grommets must be compatible with the thickness of the material you’ll be using to ensure a secure and effective installation.

- Too small grommets may not provide enough support, while too large grommets may damage the material.

Hole Size

- The grommet’s inner diameter should match the size of the hole you’ll be creating, providing a snug fit to prevent the grommet from moving or falling out.

- Accurate hole sizing is crucial to ensure proper grommet installation.

Application and Environment

- Consider the intended use and environment where the grommets will be used.

- Factors such as exposure to moisture, chemicals, or extreme temperatures may require specialized grommet materials or designs.

3. What is the process of installing grommets using a grommet machine?

- Prepare the Material: Mark the desired locations for the grommets and create holes of the appropriate size using a hole punch or other appropriate tool.

- Select the Grommet: Choose the correct grommet size and type based on the material and application requirements.

- Set Up the Grommet Machine: Adjust the machine to the appropriate settings, including the grommet size and pressure.

- Insert the Grommet: Place the grommet into the lower die of the grommet machine, aligning it with the prepared hole in the material.

- Install the Grommet: Lower the upper die onto the grommet, applying pressure to set it securely into the material.

- Inspect the Installation: Check that the grommet is properly seated and secure, and that the material is not damaged.

4. What are some common problems that can occur during grommet installation and how can they be resolved?

Grommet Not Setting Properly

- Check that the grommet size matches the hole size.

- Ensure that the grommet machine is adjusted to the correct pressure settings.

- Inspect the grommet for any damage or defects.

Grommet Pulling Through the Material

- Verify that the material is thick enough to support the grommet.

- Use a grommet with a larger flange or wider lip to provide more support.

- Consider using a self-clinching grommet that pierces and grips the material.

Grommets Not Lining Up

- Make sure that the grommet machine is properly aligned and calibrated.

- Check that the holes in the material are accurately positioned and of the same size.

- Use a template or guide to ensure consistent grommet placement.

5. What maintenance procedures are required for a grommet machine to ensure its longevity and accuracy?

- Regular Cleaning: Keep the machine clean of any debris or material residue that may accumulate during operation.

- Die Inspection: Periodically inspect the dies for wear or damage, and replace them if necessary to ensure proper grommet installation.

- Pressure Adjustment: Check and adjust the machine’s pressure settings regularly to ensure optimal grommet setting.

- Lubrication: Lubricate the machine’s moving parts according to the manufacturer’s recommendations to reduce friction and wear.

- Calibration: Regularly calibrate the machine to maintain accuracy and consistency in grommet placement and installation.

6. What are the safety precautions that should be taken when operating a grommet machine?

- Wear Proper Safety Gear: Always wear safety glasses, gloves, and appropriate clothing to protect yourself from flying debris or sharp edges.

- Keep Hands Clear: Keep your hands away from the grommet machine’s operating area, especially when it is activated.

- Secure Material: Ensure that the material being grommeted is securely held in place to prevent it from shifting or moving during the installation process.

- Unplug Before Maintenance: Always unplug the grommet machine before performing any maintenance or repairs to avoid accidental activation.

- Follow Manufacturer’s Instructions: Carefully read and follow the manufacturer’s instructions for safe operation and maintenance of the grommet machine.

7. What is your experience with different types of grommet materials?

- Metal Grommets: I have experience working with various metal grommets, including brass, aluminum, and stainless steel, for applications requiring durability and corrosion resistance.

- Plastic Grommets: I am familiar with installing plastic grommets made from materials such as nylon, polyethylene, and PVC, which offer flexibility, insulation, and lightweight properties.

- Rubber Grommets: I have used rubber grommets made from natural rubber, synthetic rubber, and silicone for applications requiring vibration dampening, sealing, and protection from harsh environments.

8. How do you ensure the accuracy and consistency of grommet placement?

- Template or Guide: I use templates or guides to mark and align the grommet placement accurately and consistently.

- Measurement and Marking: I carefully measure and mark the desired grommet locations on the material to ensure precise installation.

- Proper Calibration: I regularly calibrate the grommet machine to maintain accuracy and prevent deviations in grommet placement.

9. What techniques do you use to troubleshoot and resolve issues with grommet installation?

- Problem Identification: I first identify the root cause of the issue, whether it’s improper grommet size, incorrect pressure settings, or material incompatibility.

- Solution Implementation: Based on the identified issue, I implement appropriate solutions, such as adjusting pressure, replacing grommets, or modifying the material preparation.

- Testing and Verification: I test the resolved solution to ensure that the grommets are installed correctly and securely.

10. Can you describe a challenging grommet installation project you encountered and how you overcame it?

In a recent project, I faced a challenge installing grommets on a thick and rigid material. The standard grommets were not able to pierce through the material effectively. To overcome this, I researched and sourced specialized self-clinching grommets with sharp prongs. These grommets were able to pierce and grip the material securely, providing a robust and durable installation.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Grommet Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Grommet Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Grommet Machine Operator, your job is to operate and monitor grommet machines to produce grommets, which are small, round reinforcements that are used in a variety of products such as tarps, sails, and shoes.

1. Production

You will be responsible for setting up and operating grommet machines, ensuring that they are running smoothly and efficiently. You will also need to monitor the quality of the grommets being produced, and make adjustments to the machine as needed.

- Inspect and maintain grommet machines.

- Set up and adjust grommet machines according to specifications.

- Load and unload material into and out of grommet machines.

- Monitor the operation of grommet machines and make adjustments as needed.

- Ensure that grommets are produced to the required quality standards.

2. Maintenance

You will also be responsible for maintaining the grommet machines, including cleaning, lubricating, and making minor repairs. You will also need to keep a record of all maintenance activities.

- Perform routine maintenance and repairs on grommet machines.

- Keep a record of all maintenance activities.

- Troubleshoot and resolve problems with grommet machines.

3. Safety

As a Grommet Machine Operator, you will be responsible for following all safety procedures, including wearing appropriate safety gear and operating machines in a safe manner. You will also need to be aware of the potential hazards associated with working with grommet machines, such as sharp edges and moving parts.

- Follow all safety procedures.

- Wear appropriate safety gear.

- Operate machines in a safe manner.

- Be aware of the potential hazards associated with working with grommet machines.

4. Quality Control

As a Grommet Machine Operator, you will be responsible for ensuring that the grommets produced meet the required quality standards. You will need to inspect the grommets for defects and make adjustments to the machine as needed. You will also need to keep a record of all quality control activities.

- Inspect grommets for defects.

- Make adjustments to the machine as needed.

- Keep a record of all quality control activities.

Interview Tips

To ace your interview for a position as a Grommet Machine Operator, it is important to prepare and practice.

1. Research the company

Before your interview, take some time to research the company. This will help you understand the company’s culture, values, and what they are looking for in an ideal candidate. You can visit the company’s website, read their social media pages, and talk to people who work there.

2. Practice answering common interview questions

There are some common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It is helpful to practice answering these questions in advance so that you can deliver your answers confidently and concisely.

3. Be prepared to talk about your experience

The interviewer will want to know about your experience as a Grommet Machine Operator. Be prepared to talk about your skills and qualifications, and how they can benefit the company.

4. Be enthusiastic and positive

It is important to be enthusiastic and positive during your interview. This will show the interviewer that you are excited about the position and that you are confident in your ability to do the job.

5. Dress appropriately

First impressions matter, so it is important to dress appropriately for your interview. This means wearing clean, pressed clothes that are appropriate for a professional setting.

6. Arrive on time

Punctuality is important, so be sure to arrive on time for your interview. It is also a good idea to arrive a few minutes early so that you can relax and collect your thoughts before the interview begins.

7. Be yourself

It is important to be yourself during your interview. The interviewer wants to get to know you and see if you are a good fit for the company. So be genuine and authentic, and let your personality shine through.

Following these tips will help you prepare and ace your interview for a position as a Grommet Machine Operator.Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Grommet Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.