Are you gearing up for a career in Groover and Striper Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Groover and Striper Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

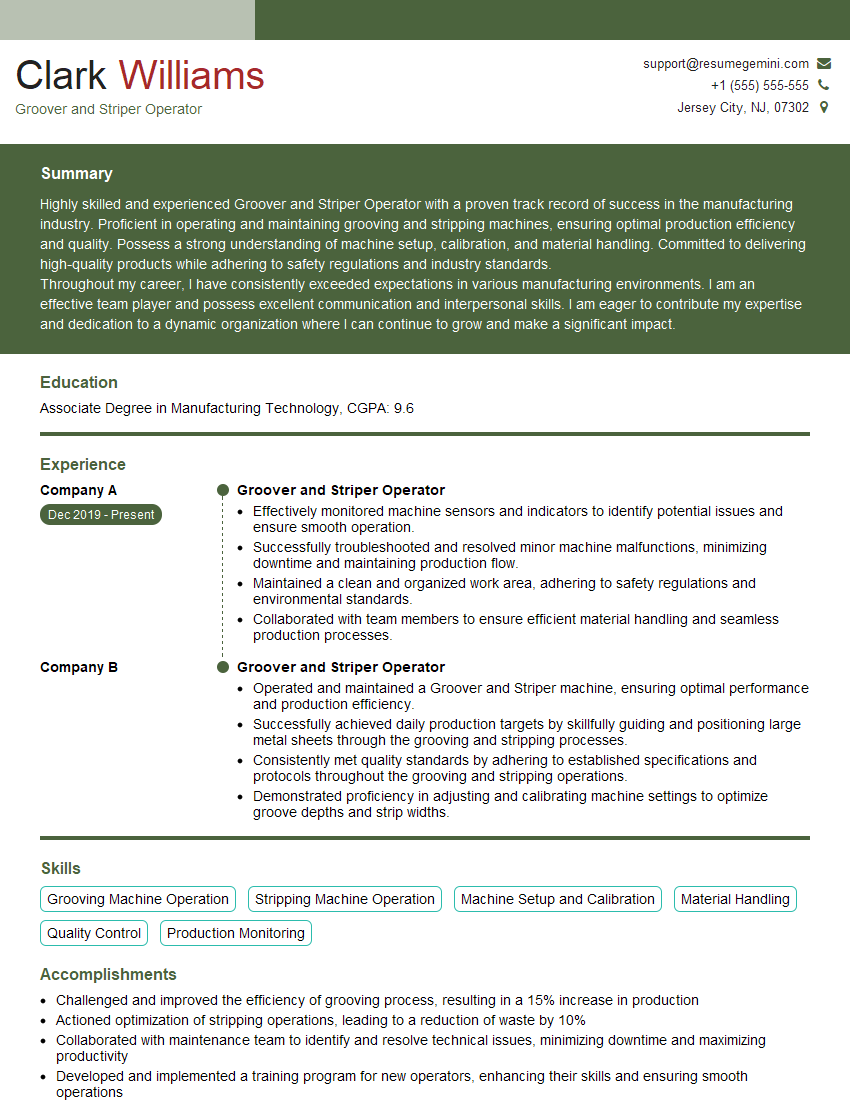

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Groover and Striper Operator

1. Explain the primary responsibilities of a Groover and Striper Operator?

As a Groover and Striper Operator, my primary responsibilities will involve operating grooving and stripping machines to create grooves or channels in concrete surfaces. This will include:

- Setting up and calibrating machines to ensure accurate cuts.

- Inspecting concrete surfaces to determine grooving patterns and depths.

- Operating machines to create grooves as per specified dimensions.

- Removing excess concrete debris from grooves and surrounding areas.

- Ensuring proper curing of grooved surfaces to enhance durability.

2. Describe the different types of grooving and stripping machines you have experience with?

Electric Groovers

- Walk-behind or ride-on machines with rotating cutter heads.

- Used for cutting shallow grooves in concrete, asphalt, or other surfaces.

Hydraulic Groovers

- Powerful machines that use hydraulic pressure to drive cutter heads.

- Capable of cutting deep grooves in various concrete surfaces.

Stripping Machines

- Machines specifically designed to remove existing grooves or strips from concrete surfaces.

- Equipped with rotating blades that grind away the old material.

3. What safety precautions should be taken when operating grooving and stripping machines?

To ensure safety during operation, I strictly adhere to the following precautions:

- Always wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and hearing protection.

- Thoroughly inspect machines and ensure they are in good working order before use.

- Set up machines in a stable and well-ventilated area.

- Maintain a safe distance from rotating cutter heads and moving parts.

- Never attempt to clear debris while the machine is running.

- Follow manufacturer’s instructions and guidelines for safe operation.

4. How do you determine the appropriate grooving pattern and depth for a specific concrete surface?

Determining the appropriate grooving pattern and depth is crucial for effective grooving. I approach this task by considering the following factors:

- Concrete Condition: Assessing the age, strength, and surface condition of the concrete helps me determine the appropriate depth and spacing of grooves.

- Purpose of Grooves: Understanding the intended purpose of the grooves, whether for drainage, expansion joints, or decorative purposes, guides my selection of pattern and depth.

- Traffic Load: The anticipated traffic load on the grooved surface influences the depth and reinforcement requirements of the grooves.

5. What are the common challenges you encounter while operating grooving and stripping machines, and how do you overcome them?

Challenges:

- Varied Concrete Conditions: Different concrete surfaces require unique grooving approaches.

- Uneven Surfaces: Grooving uneven surfaces poses technical challenges.

- Tight Deadlines: Time constraints can be demanding.

Overcoming Challenges:

- Adapting Techniques: I adjust my techniques to suit different concrete conditions, ensuring optimal results.

- Expertise in Adjustments: I possess the expertise to make necessary adjustments to machines for uneven surfaces.

- Time Management: I prioritize tasks effectively and maintain a steady pace to meet deadlines.

6. Describe a situation where you successfully resolved a technical issue with a grooving or stripping machine?

In a previous project, I encountered an issue with a hydraulic groover that was causing uneven cuts. Through troubleshooting, I identified a faulty hydraulic valve as the root cause. I promptly replaced the valve with a spare part, recalibrated the machine, and resumed operations with restored precision and efficiency.

7. How do you work as part of a construction team and collaborate with other trades on a project site?

Collaboration is crucial on construction sites. I effectively communicate with other trades to understand their requirements and ensure my grooving and stripping work aligns with the overall project plan. I proactively share updates, request assistance when needed, and adhere to safety protocols established by the team.

8. What methods do you use to ensure the quality and accuracy of your grooving and stripping work?

Quality and accuracy are paramount. I employ the following methods to ensure optimal results:

- Precise Measurements: I use calibrated measuring tools to determine grooving patterns and depths accurately.

- Regular Calibrations: I regularly calibrate grooving and stripping machines to maintain their precision.

- Quality Inspections: I conduct thorough inspections throughout the process to identify and rectify any discrepancies.

9. How do you stay up-to-date with the latest advancements in grooving and stripping techniques?

To stay current with industry advancements, I engage in the following practices:

- Attend Industry Events: I participate in conferences and workshops to learn about new techniques and technologies.

- Read Trade Publications: I regularly review industry magazines and journals to stay informed about best practices.

- Consult with Experts: I seek guidance from experienced professionals and manufacturers to gain insights into innovative approaches.

10. How do you plan and prioritize your work to ensure timely completion of projects?

Effective planning and prioritization are essential. Here’s how I approach it:

- Project Review: I thoroughly review project plans to understand the scope of work and timelines.

- Prioritization: I prioritize tasks based on their urgency, dependencies, and potential impact on the overall project.

- Time Management Techniques: I utilize tools like Gantt charts and to-do lists to track progress and allocate time effectively.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Groover and Striper Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Groover and Striper Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Groover and Striper Operator plays a crucial role in ensuring the efficient operation of a manufacturing facility by operating and maintaining grooving and stripping machines. The primary responsibilities include:

1. Machine Operation

Operate grooving and stripping machines to perform tasks such as cutting, forming, and stripping materials.

- Set up machines according to specifications.

- Monitor machine operation and make adjustments as needed.

2. Material Handling

Handle and transport materials to and from machines.

- Load and unload materials onto machines.

- Maintain a clean and organized work area.

3. Quality Control

Ensure the quality of products produced by the machines.

- Inspect products for defects.

- Report any defects or problems to supervisors.

4. Maintenance

Perform basic maintenance on machines.

- Lubricate and clean machines.

- Replace worn parts.

Interview Tips

To ace the interview for a Groover and Striper Operator position, it is important to prepare thoroughly. Here are some tips:

1. Research the Company and Position

Familiarize yourself with the company’s history, products, and culture. Research the specific job requirements and responsibilities.

- Visit the company website.

- Read industry publications and articles.

2. Practice Common Interview Questions

Prepare for typical interview questions by practicing your answers. Tailor your responses to the job description and highlight your relevant skills and experience.

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

3. Demonstrate Your Technical Knowledge

Showcase your understanding of grooving and stripping machines. Be prepared to discuss your experience in operating and maintaining these types of equipment.

- Describe the different types of grooving and stripping machines you have operated.

- Explain how you troubleshoot common problems.

4. Emphasize Your Safety Awareness

Stress your commitment to safety in the workplace. Highlight your knowledge of safety regulations and procedures.

- Describe your experience in following safety protocols.

- Explain how you ensure the safety of yourself and others in the work environment.

5. Be Enthusiastic and Professional

Show your enthusiasm for the job and the industry. Be polite, respectful, and professional throughout the interview.

- Dress appropriately.

- Arrive on time and be prepared.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Groover and Striper Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.