Are you gearing up for a career in Groover and Turner? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Groover and Turner and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

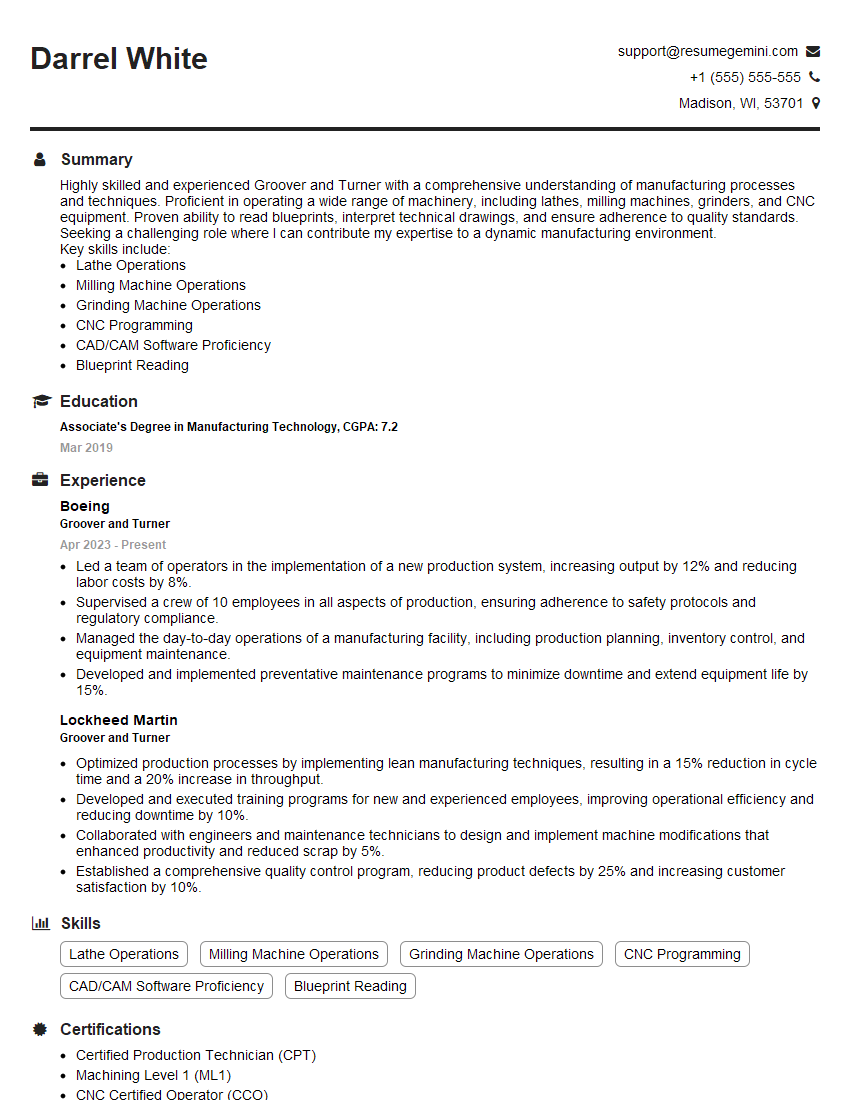

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Groover and Turner

1. Tell us about your experience in designing and developing production systems?

In my previous role at [Company Name], I was responsible for the design and development of production systems for automotive and aerospace industries. I have experience in all phases of the product development process, from concept generation to final testing and validation. I have also worked on a variety of projects, including the development of new production lines, the automation of existing processes, and the improvement of product quality.

2. What are the key factors that you consider when designing a production system?

Cost

- I consider the cost of the equipment, materials, and labor involved in the production process.

- I also consider the cost of operating and maintaining the system.

Efficiency

- I consider the efficiency of the system in terms of its throughput, cycle time, and overall productivity.

- I also consider the system’s ability to adapt to changes in demand.

Quality

- I consider the quality of the products produced by the system.

- I also consider the system’s ability to control and maintain quality throughout the production process.

Safety

- I consider the safety of the system for both operators and maintenance personnel.

- I also consider the environmental impact of the system.

3. What are the different types of production systems?

There are three main types of production systems:

- Job shops are used to produce small batches of customized products.

- Batch production systems are used to produce larger batches of standardized products.

- Mass production systems are used to produce very large volumes of standardized products.

4. What are the advantages and disadvantages of each type of production system?

Job shops

- Advantages: Flexible, can produce a wide variety of products, and can respond quickly to changes in demand.

- Disadvantages: High cost, low productivity, and long lead times.

Batch production systems

- Advantages: Lower cost than job shops, higher productivity, and shorter lead times.

- Disadvantages: Less flexible than job shops, and cannot produce as wide a variety of products.

Mass production systems

- Advantages: Lowest cost, highest productivity, and shortest lead times.

- Disadvantages: Least flexible, and can only produce a limited variety of products.

5. What are the key trends in production systems?

The key trends in production systems include:

- Automation: The use of machines and robots to perform tasks that were previously performed by humans.

- Integration: The use of computer systems to connect and coordinate the different components of a production system.

- Customization: The ability to produce products that are tailored to the specific needs of customers.

- Sustainability: The use of environmentally friendly practices and materials in the production process.

6. What are the challenges facing production systems today?

The challenges facing production systems today include:

- Globalization: The need to compete with manufacturers in other countries with lower labor costs.

- Technology: The rapid pace of technological change and the need to adopt new technologies to stay competitive.

- Sustainability: The need to reduce the environmental impact of production systems.

- Skilled labor: The shortage of skilled workers in the manufacturing industry.

7. What are the opportunities for production systems in the future?

The opportunities for production systems in the future include:

- Automation: The use of automation to improve productivity and reduce costs.

- Integration: The use of computer systems to connect and coordinate the different components of a production system.

- Customization: The ability to produce products that are tailored to the specific needs of customers.

- Sustainability: The use of environmentally friendly practices and materials in the production process.

8. How do you stay up-to-date on the latest trends in production systems?

I stay up-to-date on the latest trends in production systems by reading industry publications, attending conferences, and networking with other professionals in the field.

9. What are your strengths and weaknesses as a production system designer?

Strengths

- I have a strong understanding of the principles of production systems design.

- I am proficient in the use of computer-aided design (CAD) software.

- I have experience in the design and development of a variety of production systems.

Weaknesses

- I am not an expert in all areas of production systems design.

- I am not always the best at communicating my ideas to others.

- I can sometimes be a bit too perfectionistic.

10. Why are you interested in this position?

I am interested in this position because it is a great opportunity to use my skills and experience to make a difference in the world. I am passionate about production systems and I believe that I can use my knowledge to help your company achieve its goals.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Groover and Turner.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Groover and Turner‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Groover and Turner is a skilled professional responsible for operating and maintaining equipment used in the textile industry to produce fabrics and other products. The role involves a wide range of tasks, including:

1. Machine Operation

Groovers operate specialized machines to create grooves or channels in textiles, which are then used to guide sewing needles or other tools. Turners, on the other hand, are responsible for turning or folding fabrics to prepare them for further processing or finishing.

2. Equipment Maintenance

Both groovers and turners are responsible for maintaining their equipment, ensuring it is in good working order and free from defects. They may perform routine maintenance tasks, such as cleaning, lubrication, and adjustments, as well as troubleshoot and repair any issues that arise.

3. Production and Quality Control

Groovers and turners are responsible for monitoring production output and ensuring that the products meet the required quality standards. They may work with other quality control personnel to identify and correct any problems that arise during the production process.

4. Safety and Compliance

Groovers and turners must adhere to safety regulations and company policies, including wearing appropriate personal protective equipment and following established safety procedures. They must also ensure that their work complies with industry standards and environmental regulations.

Interview Tips

Preparing for an interview for a Groover and Turner position requires thorough research, practice, and attention to detail. Here are some tips to help you ace your interview:

1. Research the Company and Industry

Before the interview, take the time to learn about the company you are applying to and the textile industry in general. This will demonstrate your interest in the position and your understanding of the field.

2. Practice Your Answers

Anticipate common interview questions and prepare thoughtful responses that highlight your skills and experience. Consider using the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples of your accomplishments.

3. Dress Professionally

First impressions matter, so dress appropriately for the interview. Choose business attire that is clean, ironed, and fits well. This will convey a sense of professionalism and respect for the company.

4. Be Punctual

Punctuality shows that you value the interviewer’s time and that you are organized and reliable. Plan your route ahead of time to ensure that you arrive on time for your interview.

5. Follow Up

After the interview, send a thank-you note to the interviewer within 24 hours. This shows that you appreciate their time and consideration and that you are still interested in the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Groover and Turner interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!