Are you gearing up for an interview for a Groover Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Groover Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

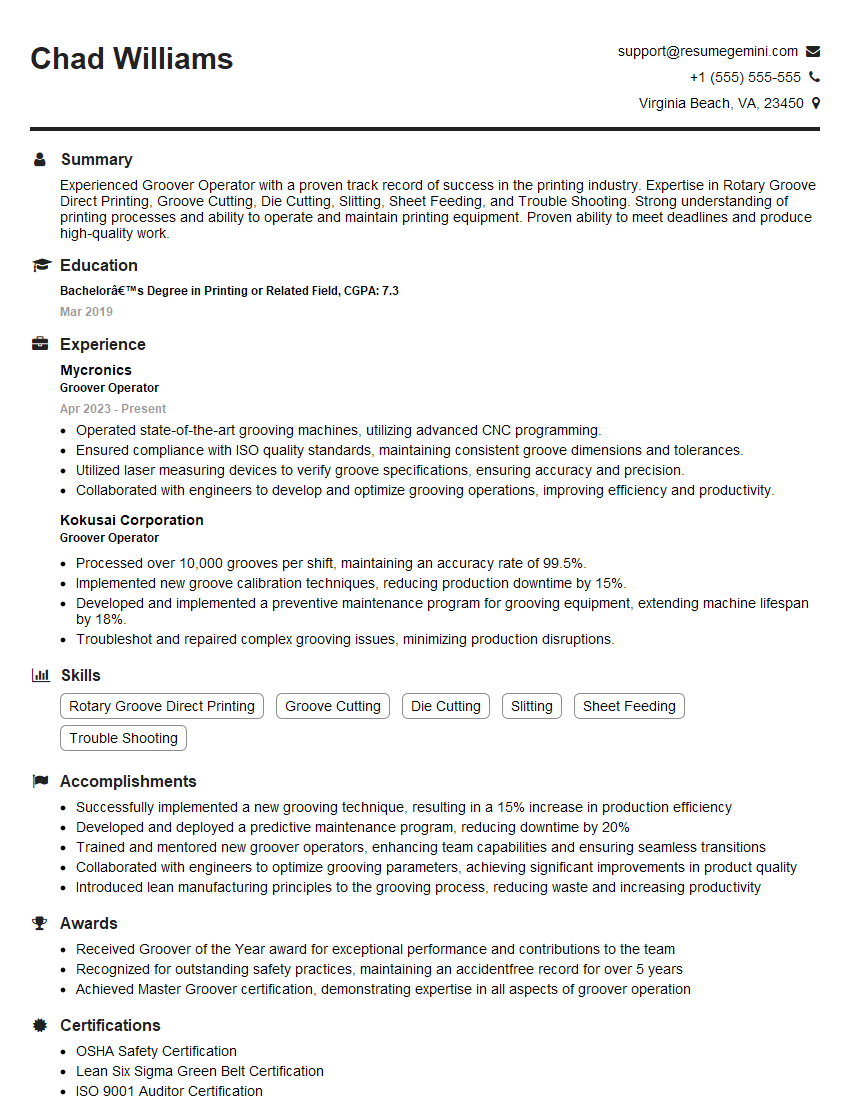

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Groover Operator

1. Explain the different types of groove operations and the equipment used for each type?

- Roughing: This operation removes excess material from the workpiece to create a general shape. It is typically performed using a roughing tool, which has a large cutting edge and a low cutting speed.

- Finishing: This operation creates a smooth, finished surface on the workpiece. It is typically performed using a finishing tool, which has a small cutting edge and a high cutting speed.

- Profiling: This operation creates a specific shape or profile on the workpiece. It is typically performed using a profiling tool, which has a cutting edge that matches the desired shape.

- Threading: This operation creates a threaded surface on the workpiece. It is typically performed using a threading tool, which has a spiral cutting edge that matches the desired thread.

- Boring: This operation creates a hole in the workpiece. It is typically performed using a boring tool, which has a cutting edge that is shaped like a cone.

2. What are the different types of materials that can be grooved?

- Metals: Metals are commonly grooved, including steel, aluminum, and brass.

- Plastics: Plastics can also be grooved, but they require special tools and techniques.

- Wood: Wood is a popular material for grooving, and it can be grooved using a variety of tools.

3. What are the factors that need to be considered when selecting a grooving tool?

- Type of material: The type of material being grooved will determine the type of tool that is needed.

- Groove size: The size of the groove will determine the size of the tool that is needed.

- Groove shape: The shape of the groove will determine the type of tool that is needed.

- Tool speed: The speed of the tool will affect the quality of the groove.

- Feed rate: The feed rate of the tool will affect the speed at which the groove is created.

4. What are the safety precautions that need to be taken when using a grooving tool?

- Wear safety glasses: Safety glasses will protect your eyes from flying chips and debris.

- Wear gloves: Gloves will protect your hands from cuts and abrasions.

- Use a sharp tool: A sharp tool will cut more cleanly and reduce the risk of accidents.

- Secure the workpiece: The workpiece should be securely clamped in place to prevent it from moving during the grooving operation.

- Use a proper setup: The grooving tool should be properly set up and aligned to ensure that the groove is cut accurately.

5. What are the common problems that can occur when grooving and how can they be prevented?

- Chatter: Chatter is a vibration that can occur when the grooving tool is not properly aligned or when the feed rate is too high. Chatter can be prevented by using a sharp tool, securing the workpiece properly, and using a proper setup.

- Burrs: Burrs are small, sharp edges that can be left on the workpiece after grooving. Burrs can be prevented by using a sharp tool and by using a proper setup.

- Gouging: Gouging is a condition where the grooving tool digs into the workpiece and creates a deep groove. Gouging can be prevented by using a sharp tool and by using a proper setup.

6. How do you maintain a grooving tool?

- Keep the tool clean: The grooving tool should be cleaned regularly to remove chips and debris.

- Sharpen the tool: The grooving tool should be sharpened regularly to ensure that it cuts cleanly.

- Inspect the tool: The grooving tool should be inspected regularly for wear and damage.

7. What are the advantages of using a CNC grooving machine?

- Precision: CNC grooving machines are very precise and can produce grooves with high accuracy.

- Repeatability: CNC grooving machines can produce grooves that are repeatable and consistent.

- Efficiency: CNC grooving machines are very efficient and can produce grooves quickly and accurately.

8. What are the different types of CNC grooving machines?

- Horizontal CNC grooving machines: Horizontal CNC grooving machines have the spindle mounted horizontally.

- Vertical CNC grooving machines: Vertical CNC grooving machines have the spindle mounted vertically.

- Gantry CNC grooving machines: Gantry CNC grooving machines have the spindle mounted on a gantry that moves over the workpiece.

9. What are the factors that need to be considered when selecting a CNC grooving machine?

- Type of material: The type of material being grooved will determine the type of CNC grooving machine that is needed.

- Groove size: The size of the groove will determine the size of the CNC grooving machine that is needed.

- Groove shape: The shape of the groove will determine the type of CNC grooving machine that is needed.

- Production volume: The production volume will determine the speed and accuracy of the CNC grooving machine that is needed.

- Budget: The budget will determine the price of the CNC grooving machine that is purchased.

10. What are the common problems that can occur with CNC grooving machines and how can they be prevented?

- Tool wear: Tool wear is a common problem with CNC grooving machines. Tool wear can be prevented by using a sharp tool and by using a proper setup.

- Workpiece damage: Workpiece damage can occur if the CNC grooving machine is not properly set up or if the tool is not sharp. Workpiece damage can be prevented by using a proper setup and by using a sharp tool.

- Machine downtime: Machine downtime can occur if the CNC grooving machine is not properly maintained or if there is a problem with the machine. Machine downtime can be prevented by performing regular maintenance on the machine and by troubleshooting any problems that occur.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Groover Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Groover Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities:

The Groover Operator plays a pivotal role in the production process, ensuring efficient operation and adherence to quality standards.

1. Machinery Operation:

Operate and monitor grooving machines to create precise grooves and shapes in metal or non-metallic workpieces.

- Set up and calibrate machines according to specifications.

- Monitor machine performance and make necessary adjustments to maintain optimal output.

2. Quality Control:

Inspect finished workpieces to ensure they meet required dimensions, tolerances, and surface finishes.

- Utilize measuring tools such as micrometers, calipers, and gauges.

- Identify and correct any defects or deviations from specifications.

3. Production Planning and Scheduling:

Collaborate with the production team to plan and schedule grooving operations.

- Estimate machine cycle times and capacity.

- Coordinate with other departments to ensure timely delivery of workpieces.

4. Maintenance:

Perform routine maintenance and troubleshooting on grooving machines.

- Lubricate, clean, and inspect machines regularly.

- Identify and resolve minor issues, and escalate major repairs to maintenance crew.

Interview Preparation Tips:

Interview questions may vary depending on the specific industry and company, but these general tips can help candidates prepare for success:

1. Research the Industry and Company:

Understand the grooving industry’s trends, major players, and the specific company’s market position.

- Visit the company website and industry publications.

- Identify the company’s key products, services, and competitors.

2. Practice Your Answers:

Anticipate common interview questions and prepare thoughtful responses.

- Use the STAR method to structure your answers: Situation, Task, Action, Result.

- Quantify your achievements with specific metrics and data whenever possible.

3. Highlight Your Skills and Experience:

Emphasize how your skills and experience align with the Groover Operator job requirements.

- Showcase your proficiency in grooving machine operation, quality control, and production planning.

- Provide examples of your success in meeting or exceeding production goals.

4. Be Prepared to Discuss Safety:

Safety is paramount in manufacturing environments. Demonstrate your understanding of workplace safety protocols.

- Explain your adherence to safety guidelines and your role in accident prevention.

- Discuss your experience with safety equipment and personal protective gear (PPE).

5. Ask Informed Questions:

Asking thoughtful questions shows your interest and engagement.

- Inquire about the company’s grooving capabilities and its plans for the future.

- Ask about opportunities for professional development and advancement.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Groover Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!