Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Grooving Lathe Tender interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Grooving Lathe Tender so you can tailor your answers to impress potential employers.

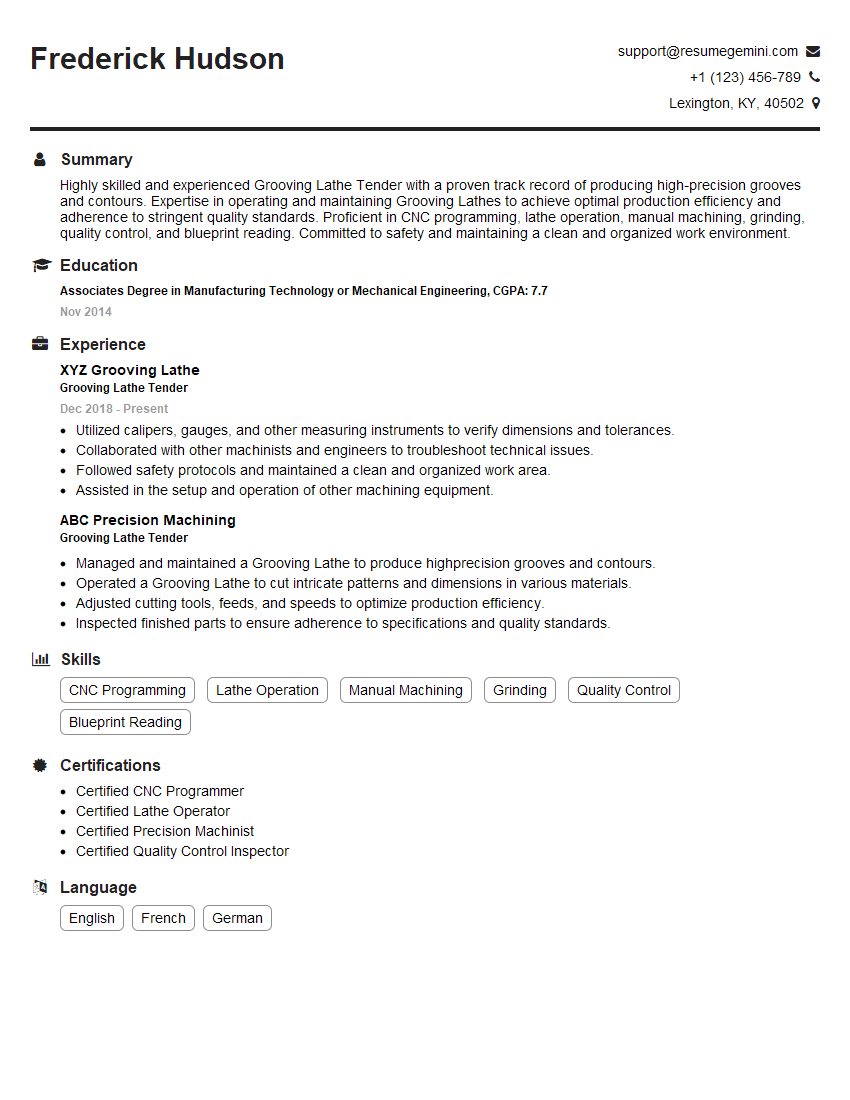

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Grooving Lathe Tender

1. What are the safety precautions that should be taken while operating a grooving lathe?

- Wear appropriate safety gear, including gloves, safety glasses, and earplugs.

- Ensure that the lathe is properly grounded and that all guards are in place.

- Inspect the workpiece and cutting tool before starting the lathe.

- Keep your hands away from the rotating workpiece.

- Be aware of the location of the stop button in case of an emergency.

2. How do you set up a grooving lathe for a specific grooving job?

Measure and mark the workpiece

- Use a measuring tape or ruler to measure and mark the location of the groove.

- Use a center punch to mark the starting and ending points of the groove.

Mount the workpiece

- Place the workpiece on the lathe chuck and tighten it securely.

- Align the workpiece with the center line of the lathe.

Select and install the cutting tool

- Select a grooving tool with the appropriate width and depth for the groove.

- Install the cutting tool in the tool post and adjust it to the correct height.

Set the lathe speed and feed rate

- Set the lathe speed to the appropriate setting for the material being cut.

- Set the feed rate to the appropriate setting for the desired groove depth.

3. What are the different types of grooving tools that can be used on a grooving lathe?

- Single-point grooving tools

- Multi-point grooving tools

- Form grooving tools

4. What are the advantages and disadvantages of using single-point grooving tools?

Advantages

- Can be used to create a variety of groove shapes and sizes

- Relatively inexpensive

- Easy to set up and use

Disadvantages

- Can be time-consuming to use

- Not as accurate as other types of grooving tools

5. What are the advantages and disadvantages of using multi-point grooving tools?

Advantages

- Faster than single-point grooving tools

- More accurate than single-point grooving tools

- Can be used to create a variety of groove shapes and sizes

Disadvantages

- More expensive than single-point grooving tools

- More difficult to set up and use

6. What are the advantages and disadvantages of using form grooving tools?

Advantages

- Fastest type of grooving tool

- Most accurate type of grooving tool

- Can be used to create complex groove shapes

Disadvantages

- Most expensive type of grooving tool

- Most difficult to set up and use

7. What are the different factors that affect the groove quality when grooving on a lathe?

- The type of grooving tool

- The material being cut

- The lathe speed

- The feed rate

- The depth of cut

8. How do you troubleshoot common grooving problems?

- Chatter: Reduce the lathe speed or feed rate, or use a sharper cutting tool.

- Tearing: Increase the lathe speed or feed rate, or use a less sharp cutting tool.

- Burrs: Use a sharp cutting tool and a light feed rate.

- Groove is too wide: Use a narrower cutting tool or reduce the depth of cut.

- Groove is too narrow: Use a wider cutting tool or increase the depth of cut.

9. What are the maintenance procedures for a grooving lathe?

- Clean and lubricate the lathe regularly.

- Inspect the lathe for any damage or wear and tear.

- Sharpen or replace the cutting tools as needed.

- Calibrate the lathe regularly to ensure accuracy.

10. What are the safety regulations that must be followed when operating a grooving lathe?

- Wear appropriate safety gear, including gloves, safety glasses, and earplugs.

- Ensure that the lathe is properly grounded and that all guards are in place.

- Inspect the workpiece and cutting tool before starting the lathe.

- Keep your hands away from the rotating workpiece.

- Be aware of the location of the stop button in case of an emergency.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Grooving Lathe Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Grooving Lathe Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Grooving Lathe Tender operates a lathe machine to cut or shape grooves into metal workpieces. They ensure the machine is set up and running properly, and they monitor the progress of the work to ensure that it meets specifications.

1. Machine Operation

The primary responsibility of a Grooving Lathe Tender is to operate the lathe machine. This involves setting up the machine, loading the workpiece, and starting the cutting process. They must also monitor the machine’s progress to ensure that it is running smoothly and that the workpiece is being cut to the correct specifications.

- Set up and operate a lathe machine to cut or shape grooves into metal workpieces.

- Load and unload workpieces from the machine.

- Monitor the machine’s progress to ensure that it is running smoothly and that the workpiece is being cut to the correct specifications.

2. Workpiece Preparation

Before a Grooving Lathe Tender can begin cutting, they must first prepare the workpiece. This involves cleaning the workpiece, applying a lubricant, and marking the areas that need to be cut. They must also ensure that the workpiece is properly secured in the machine.

- Clean and prepare workpieces for cutting.

- Apply lubricants to workpieces.

- Mark areas on workpieces that need to be cut.

- Secure workpieces in the machine.

3. Cutting Process

Once the workpiece is prepared, the Grooving Lathe Tender can begin the cutting process. They must select the correct cutting tool and set the machine to the correct speed and feed rate. They must also monitor the cutting process to ensure that it is progressing smoothly.

- Select the correct cutting tool for the job.

- Set the machine to the correct speed and feed rate.

- Monitor the cutting process to ensure that it is progressing smoothly.

4. Quality Control

Once the cutting process is complete, the Grooving Lathe Tender must inspect the workpiece to ensure that it meets the required specifications. They must also clean the machine and tools.

- Inspect workpieces to ensure that they meet the required specifications.

- Clean the machine and tools.

Interview Tips

Preparing well for an interview can significantly increase your chances of making a positive impression on the interviewer and landing the job. Here are some tips to help you prepare for your interview for a Grooving Lathe Tender position:

1. Research the Company and the Position

Before your interview, take some time to research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and goals, as well as the specific responsibilities of the role. You can find information about the company on their website, social media pages, and Glassdoor.

- Visit the company’s website to learn about their history, products, services, and culture.

- Check out the company’s social media pages to get a sense of their company culture and values.

- Read reviews of the company on Glassdoor to get insights into the interview process and the company’s work environment.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice answering these questions in advance so that you can deliver your answers confidently and concisely.

- Prepare a brief introduction of yourself, including your educational background, work experience, and skills.

- Identify your key strengths and weaknesses, and be prepared to discuss how they relate to the requirements of the position.

- Research the company and the industry, and be prepared to discuss your understanding of the company’s business model and the challenges facing the industry.

3. Highlight Your Skills and Experience

In your interview, be sure to highlight your skills and experience that are most relevant to the position you are applying for. For example, if you have experience operating a lathe machine, be sure to mention this in your interview. You should also be prepared to discuss your problem-solving skills, your attention to detail, and your ability to work independently.

- Quantify your accomplishments whenever possible. For example, instead of saying “I managed a team of engineers,” you could say “I managed a team of engineers and led them to achieve a 20% increase in productivity.”

- Use action verbs to describe your skills and experience. For example, instead of saying “I am a skilled lathe operator,” you could say “I have operated a lathe machine for the past 5 years and have experience cutting a variety of materials.”

4. Ask Questions

At the end of your interview, be sure to ask the interviewer any questions you have about the position or the company. This shows that you are interested in the job and that you are taking the interview seriously. It is also a good opportunity to learn more about the company and the position.

- Ask about the company’s culture and values.

- Ask about the specific responsibilities of the position.

- Ask about the company’s plans for the future.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Grooving Lathe Tender interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!