Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Ground Water Pump Installer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Ground Water Pump Installer so you can tailor your answers to impress potential employers.

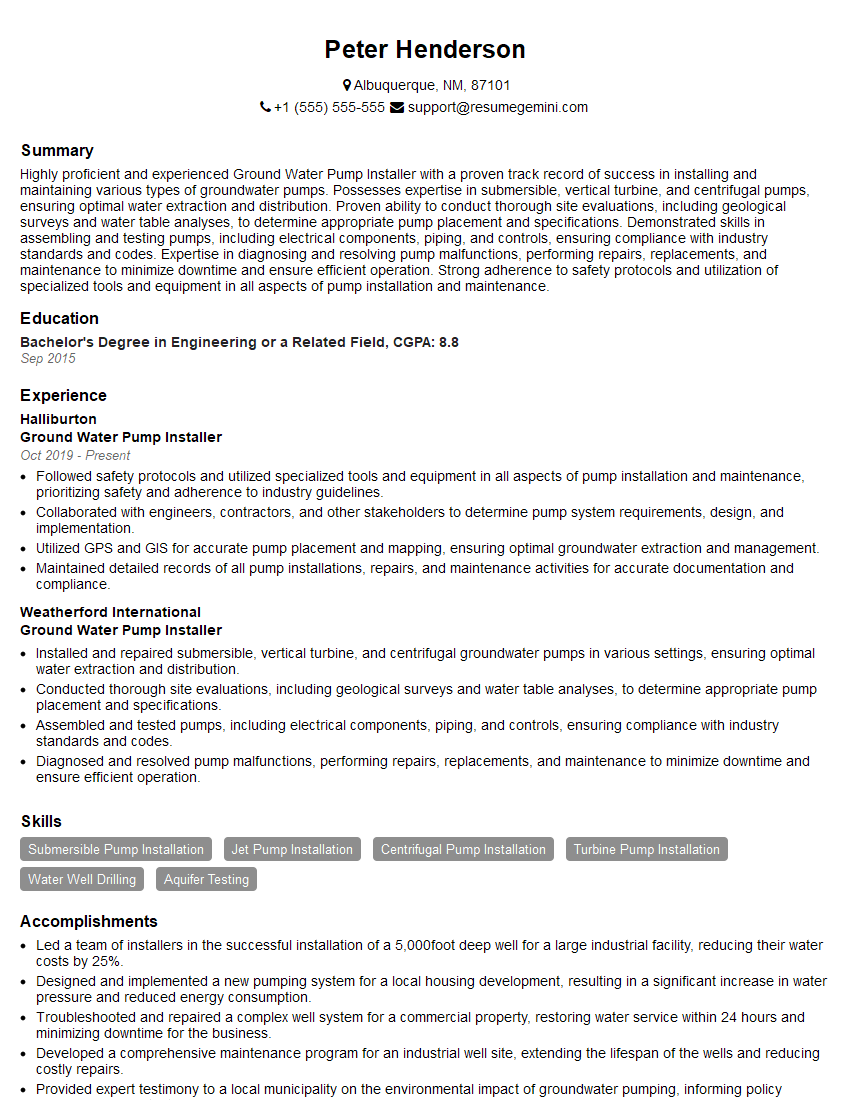

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ground Water Pump Installer

1. What are the different types of water pumps used in groundwater extraction?

There are several types of water pumps used in groundwater extraction, each with its own advantages and disadvantages. Some of the most common types include:

- Submersible pumps: These pumps are installed below the water level and are designed to operate in submerged conditions. They are typically used for high-volume pumping applications.

- Jet pumps: These pumps use a venturi effect to create a vacuum that draws water up from the well. They are typically used for low-volume pumping applications.

- Centrifugal pumps: These pumps use a rotating impeller to create a centrifugal force that pumps water up from the well. They are typically used for medium-volume pumping applications.

2. What are the key considerations when selecting a water pump for a groundwater extraction project?

Factors to consider when selecting a water pump for a groundwater extraction project:

- The depth of the well

- The volume of water that needs to be pumped

- The pressure that is required to deliver the water to its destination

- The type of water that is being pumped (e.g., clean water, dirty water, saltwater)

- The budget for the project

In addition to these factors, it is also important to consider the following:

- The efficiency of the pump

- The noise level of the pump

- The durability of the pump

- The availability of maintenance and repair services

3. What are the common problems that can occur with groundwater pumps and how can they be resolved?

Some of the most common problems that can occur with groundwater pumps include:

- Pump failure: This can be caused by a variety of factors, such as power outages, overheating, or mechanical failure. To resolve this problem, the pump will need to be repaired or replaced.

- Clogged pump: This can be caused by sediment, debris, or other foreign objects getting into the pump. To resolve this problem, the pump will need to be cleaned.

- Leaking pump: This can be caused by a variety of factors, such as worn seals or gaskets. To resolve this problem, the pump will need to be repaired or replaced.

4. What are the safety precautions that should be taken when working with groundwater pumps?

When working with groundwater pumps, it is important to take the following safety precautions:

- Always wear appropriate safety gear, such as gloves, safety glasses, and a hard hat.

- Never work on a pump that is energized.

- Be aware of the location of all electrical wires and cables.

- Do not attempt to repair a pump that is beyond your level of expertise.

- Always follow the manufacturer’s instructions for operating and maintaining the pump.

5. What are the different types of groundwater monitoring systems and how do they work?

Types of groundwater monitoring systems:

- Manual monitoring systems: These systems involve collecting water samples from wells and analyzing them in a laboratory. This is the most basic type of groundwater monitoring system, but it can be time-consuming and expensive.

- Automated monitoring systems: These systems use sensors to collect data on groundwater levels and water quality. The data is then transmitted to a central location, where it can be analyzed and stored. Automated monitoring systems are more expensive than manual monitoring systems, but they can provide more frequent and accurate data.

How groundwater monitoring systems work:

- Manual monitoring systems: Water samples are collected from wells using a variety of methods, such as bailers, pumps, or samplers. The samples are then analyzed in a laboratory to determine the levels of contaminants present.

- Automated monitoring systems: Sensors are placed in wells to collect data on groundwater levels and water quality. The data is then transmitted to a central location, where it can be analyzed and stored. Automated monitoring systems can be programmed to collect data at regular intervals, or they can be triggered to collect data when certain conditions are met.

6. What are the benefits of using a groundwater monitoring system?

Groundwater monitoring systems can provide a number of benefits, including:

- Early detection of contamination: Groundwater monitoring systems can help to detect contamination early on, before it has a chance to spread and cause harm. This can help to protect public health and the environment.

- Tracking the movement of contamination: Groundwater monitoring systems can help to track the movement of contamination, which can help to identify the source of the contamination and to develop strategies to contain it.

- Evaluating the effectiveness of remediation efforts: Groundwater monitoring systems can help to evaluate the effectiveness of remediation efforts by tracking the levels of contamination over time. This information can be used to adjust the remediation strategy as needed.

7. What are the challenges of installing and maintaining a groundwater monitoring system?

There are a number of challenges associated with installing and maintaining a groundwater monitoring system, including:

- Cost: Groundwater monitoring systems can be expensive to install and maintain. The cost of the system will vary depending on the size and complexity of the system.

- Technical expertise: Installing and maintaining a groundwater monitoring system requires technical expertise. It is important to hire a qualified contractor to perform these tasks.

- Access to wells: It is important to have access to wells in order to install and maintain a groundwater monitoring system. This can be difficult in areas where there are few wells or where the wells are located on private property.

8. What are the different types of groundwater remediation technologies?

There are a number of different groundwater remediation technologies available, each with its own advantages and disadvantages. Some of the most common technologies include:

- Pump-and-treat: This technology involves pumping contaminated groundwater out of the ground and treating it above ground. The treated water is then reinjected into the ground.

- In-situ remediation: This technology involves treating the contaminated groundwater in place. This can be done using a variety of methods, such as chemical oxidation, bioremediation, or thermal treatment.

- Permeable reactive barriers: This technology involves installing a barrier of reactive material in the ground. The barrier reacts with the contaminated groundwater and removes the contaminants.

9. What are the factors that affect the selection of a groundwater remediation technology?

The selection of a groundwater remediation technology depends on a number of factors, including:

- The type of contamination

- The concentration of the contamination

- The geology of the site

- The hydrogeology of the site

- The cost of the technology

10. What are the challenges of groundwater remediation?

Groundwater remediation is a challenging process, and there are a number of factors that can affect the success of a remediation project. Some of the most common challenges include:

- The heterogeneity of the subsurface: The subsurface is often heterogeneous, which can make it difficult to design and implement a remediation strategy that will be effective throughout the entire site.

- The presence of non-aqueous phase liquids (NAPLs): NAPLs are immiscible with water, and they can be difficult to remove from the subsurface.NAPLs can also act as a source of contamination for groundwater.

- The cost of remediation: Groundwater remediation can be expensive, and it is important to carefully consider the costs and benefits of different remediation technologies before making a decision.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ground Water Pump Installer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ground Water Pump Installer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Ground Water Pump Installers are responsible for the installation, repair, and maintenance of groundwater pumps. They work independently or as part of a team to ensure that water is available for residential, commercial, and industrial purposes.

1. Installation

Install groundwater pumps in accordance with blueprints and specifications.

- Determine the best location for the pump.

- Dig a hole for the pump.

- Connect the pump to the water source.

- Install the pump in the hole.

- Backfill the hole and compact the soil.

2. Repair

Repair groundwater pumps that are not working properly.

- Troubleshoot the problem.

- Replace or repair the damaged parts.

- Test the pump to make sure it is working properly.

3. Maintenance

Perform regular maintenance on groundwater pumps to prevent problems.

- Inspect the pump for wear and tear.

- Lubricate the moving parts.

- Clean the pump.

- Test the pump to make sure it is working properly.

4. Other Duties

In addition to the above, Ground Water Pump Installers may also be responsible for the following:

- Providing customer service.

- Working with other tradespeople, such as plumbers and electricians.

- Maintaining a clean and organized work area.

- Following safety regulations.

Interview Tips

There are a few things you can do to prepare for your interview for a Ground Water Pump Installer position. Here are some tips:

1. Research the company

Before your interview, take some time to learn about the company you are applying to. This will show the interviewer that you are interested in the position and that you have taken the time to learn about the company’s culture and values.

2. Practice your answers to common interview questions

There are a few common interview questions that you are likely to be asked, such as “Why do you want to work for our company?” and “What are your strengths and weaknesses?”. Take some time to practice your answers to these questions so that you can deliver them confidently and concisely.

3. Be prepared to talk about your experience

The interviewer will want to know about your experience as a Ground Water Pump Installer. Be prepared to talk about your skills and knowledge, as well as any specific projects that you have worked on.

4. Be professional and enthusiastic

First impressions matter, so it is important to dress professionally and be enthusiastic during your interview. Make eye contact with the interviewer, smile, and be polite and respectful.

5. Ask questions

At the end of the interview, the interviewer will likely ask if you have any questions. This is your opportunity to learn more about the position and the company. Ask thoughtful questions that show that you are interested in the position and that you are eager to learn more.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Ground Water Pump Installer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!