Are you gearing up for an interview for a Guillotine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Guillotine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

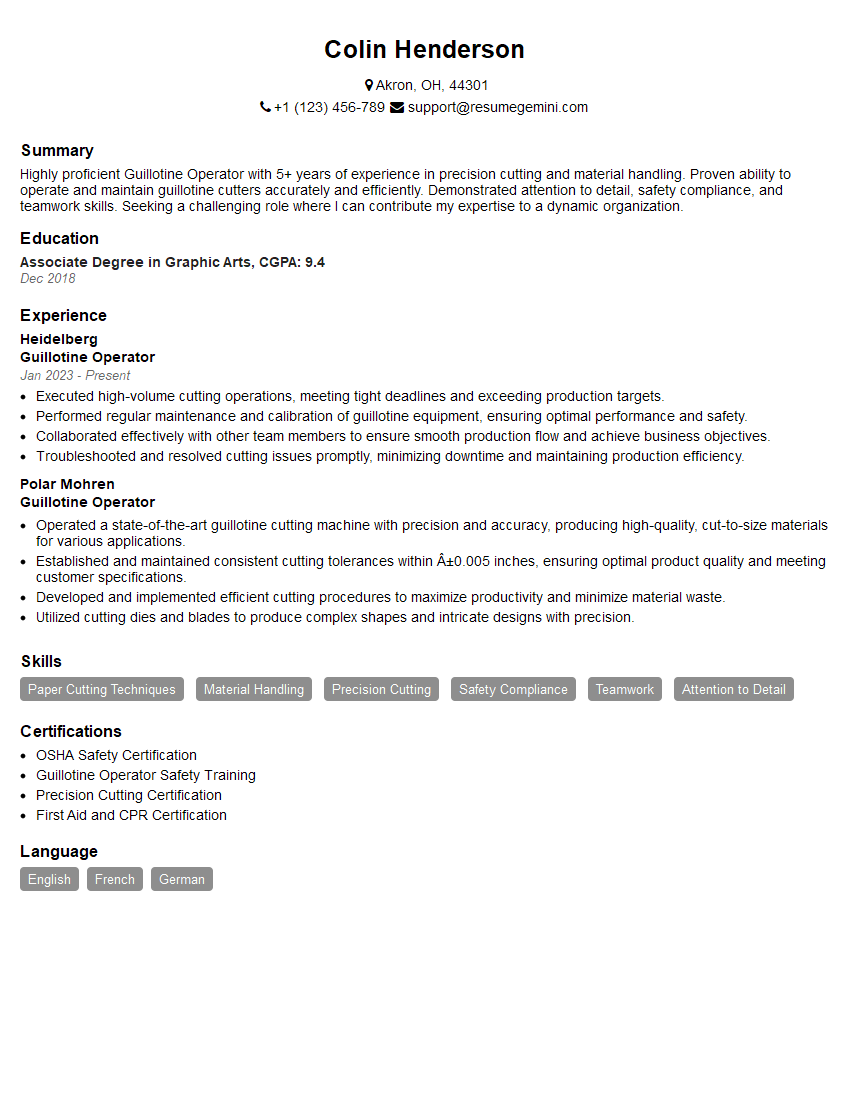

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Guillotine Operator

1. What are the different types of guillotine cutters and their uses?

- Vertical Guillotine: Used for general cutting, offers precise and clean cuts.

- Horizontal Guillotine: Designed for larger materials, provides high accuracy and efficiency.

- Lever Guillotine: Manual cutter, suitable for small-scale operations and intricate cuts.

- Hydraulic Guillotine: Powered by hydraulic cylinders, delivers high cutting force for thick materials.

- Digital Guillotine: Equipped with computer-controlled systems, enables automated cutting and reduces setup time.

2. How do you ensure accurate cutting with a guillotine cutter?

- Properly calibrate and maintain the cutter to ensure precise blade alignment.

- Use sharp blades and replace them regularly to minimize tear and ensure clean cuts.

- Secure the material firmly using clamps or a back gauge to prevent movement during cutting.

- Set the cutting depth accurately using the depth gauge and adjust it as needed.

- Ensure the material is straight and free of any obstacles before cutting to prevent damage to the blade.

3. What safety precautions should be taken when operating a guillotine cutter?

- Wear appropriate safety gear, including gloves, safety glasses, and earplugs.

- Keep hands and fingers away from the blade area during operation.

- Inspect the cutter regularly for any defects or damage and report them promptly.

- Ensure proper lighting around the cutting area to enhance visibility.

- Never operate the cutter under the influence of drugs or alcohol.

4. How do you troubleshoot common issues with guillotine cutters?

- Blade Misalignment: Adjust the blade alignment or replace the blade if necessary.

- Inaccurate Cuts: Calibrate the cutter, check the sharpness of the blade, or secure the material properly.

- Excessive Wear on Blade: Use a sharp blade and replace it regularly.

- Hydraulic System Malfunction: Contact a qualified technician for repairs.

- Electrical Problems: Check the power supply, fuses, and wiring; contact an electrician if needed.

5. Can you describe the process of setting up a guillotine cutter for a specific cutting job?

- Determine the required cut dimensions and material specifications.

- Select the appropriate blade and set the cutting depth using the gauge.

- Secure the material using clamps or a back gauge and align it with the blade.

- Set up the safety features and ensure the cutting area is clear.

- Operate the cutter carefully, following the safety guidelines.

6. What are the maintenance and cleaning requirements for a guillotine cutter?

- Regularly clean the cutter using a soft cloth and mild detergent.

- Oil and lubricate moving parts according to the manufacturer’s instructions.

- Inspect the blade for sharpness and replace it when necessary.

- Maintain the hydraulic system by changing the oil and filters as recommended.

- Perform safety checks and report any issues to the supervisor or maintenance team.

7. How do you handle different types of materials in a guillotine cutter?

- Cardboard and Paper: Adjust the cutting depth and use a sharp blade for clean cuts.

- Plastics: Use specialty blades designed for plastic materials and adjust the cutting depth accordingly.

- Metals: Utilize blades suitable for metal cutting and ensure proper support for the material.

- Fabrics: Use sharp blades and set the cutting depth carefully to avoid tearing.

- Laminates: Adjust the cutting depth and use a sharp blade specifically for laminates.

8. How do you calculate the cutting capacity of a guillotine cutter?

- Consider the maximum thickness and width of the material to be cut.

- Refer to the manufacturer’s specifications for the rated cutting capacity.

- Account for any limitations imposed by the blade material and sharpness.

- Take into consideration the cutting speed and feed rate for efficient operation.

9. What are the advantages and disadvantages of using a guillotine cutter compared to other cutting methods?

Advantages:

- High precision and accuracy in cutting.

- Efficient for repetitive cutting operations.

- Versatile, can handle various materials.

- Durable and long-lasting with proper maintenance.

Disadvantages:

- Can be noisy and generate waste material.

- Requires operator training and safety precautions.

- Limitations in cutting complex shapes or curves.

10. How do you stay updated with the latest advancements in guillotine cutting technology?

- Attend industry trade shows and conferences.

- Read trade publications and technical journals.

- Participate in online forums and discussions.

- Consult with equipment manufacturers and suppliers.

- Seek training and certification programs.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Guillotine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Guillotine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Guillotine Operators are responsible for operating guillotine machines to cut various materials, such as paper, plastic, and metal, to precise specifications. They also perform machine maintenance and setup, as well as ensure that the work area is safe and clean.

1. Operate Guillotine Machine

Guillotine Operators use guillotine machines to cut materials to specific lengths and shapes. They must be able to accurately set up the machine and make precise cuts. They should also be familiar with different types of materials and their cutting requirements.

- Set up the guillotine machine according to the job specifications.

- Load the material to be cut into the machine.

- Operate the machine to cut the material to the desired length and shape.

- Unload the cut material from the machine.

2. Machine Maintenance and Setup

Guillotine Operators are responsible for maintaining and setting up the guillotine machine. They must be able to identify and troubleshoot problems, as well as perform basic maintenance and repairs. They must also be able to set up the machine for different types of jobs.

- Inspect the machine regularly for wear and tear.

- Perform basic maintenance and repairs on the machine.

- Troubleshoot problems with the machine.

- Set up the machine for different types of jobs.

3. Work Area Safety

Guillotine Operators must ensure that the work area is safe and clean. They must be aware of the potential hazards associated with operating a guillotine machine, and they must take steps to prevent accidents.

- Keep the work area clean and free of debris.

- Follow all safety procedures when operating the guillotine machine.

- Report any unsafe conditions to a supervisor immediately.

4. Job Planning and Quality Assurance

Guillotine Operators must be able to plan and execute jobs efficiently. They must also be able to inspect the finished product to ensure that it meets quality standards.

- Plan and execute jobs in a timely and efficient manner.

- Inspect the finished product to ensure that it meets quality standards.

- Take corrective action if the finished product does not meet quality standards.

Interview Tips

Preparing for a job interview can be daunting, but it’s important to remember that the interviewer wants to get to know you and your skills. By following these tips, you can increase your chances of making a great impression and landing the job.

1. Research the Company

Before the interview, take some time to research the company. This will help you understand the company’s culture, values, and goals. It will also help you answer questions about the company and why you’re interested in the position.

- Visit the company’s website

- Read the company’s social media pages

- Talk to people who work at the company

2. Practice Answering Common Interview Questions

There are a few common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It’s helpful to practice answering these questions in advance so that you can deliver clear and concise responses during the interview.

- Write out your answers to common interview questions

- Practice saying your answers out loud

- Get feedback from a friend or family member

3. Dress Professionally

First impressions matter, so it’s important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the job you’re applying for. You should also make sure that your shoes are clean and polished.

- Choose clothes that are clean, pressed, and appropriate for the job

- Make sure your shoes are clean and polished

- Avoid wearing too much jewelry or perfume

4. Be On Time

Punctuality is important, so make sure to arrive on time for your interview. If you’re running late, call the interviewer to let them know. It’s also a good idea to arrive a few minutes early so that you have time to relax and compose yourself before the interview.

- Give yourself plenty of time to get to the interview

- If you’re running late, call the interviewer to let them know

- Arrive a few minutes early so that you have time to relax

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Guillotine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!