Feeling lost in a sea of interview questions? Landed that dream interview for Gusset Maker but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Gusset Maker interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

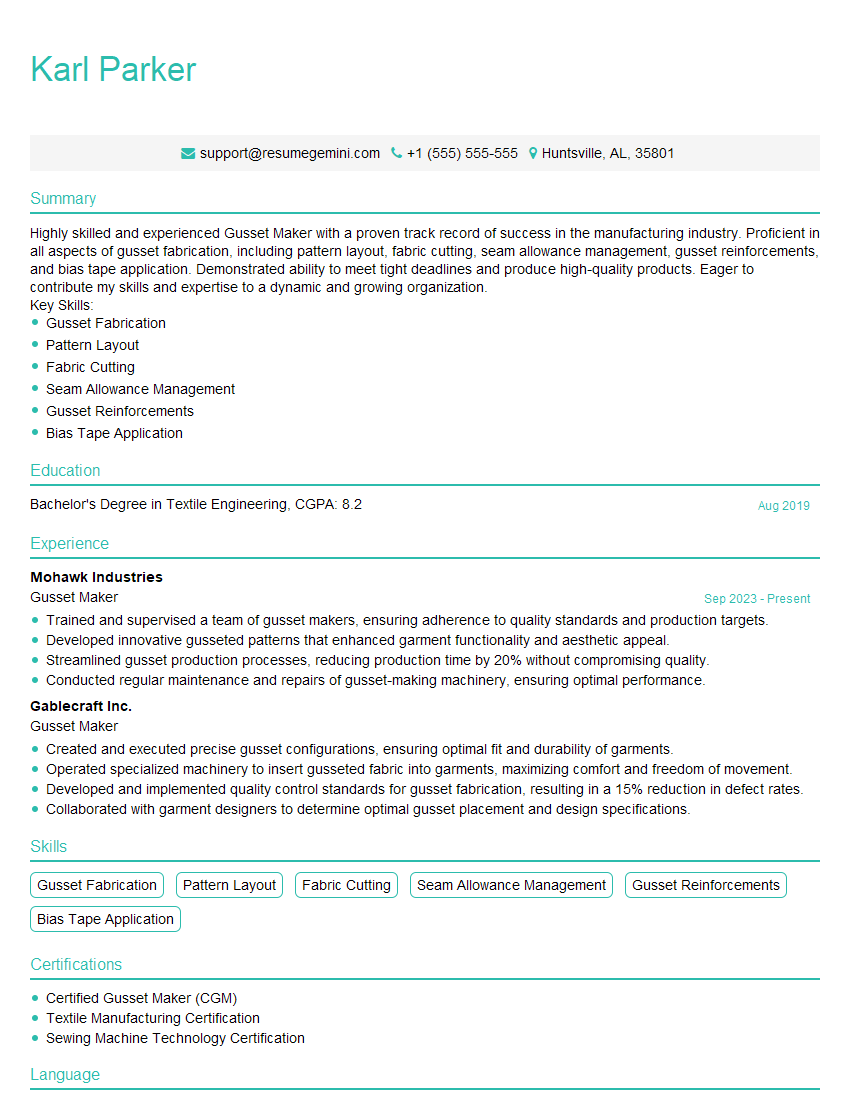

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Gusset Maker

1. What are the different types of gussets you have worked with?

Gussets can be classified into various types based on their shape, material, and application. Some common types of gussets include:

- Triangular gussets: These are the most common type of gussets and are typically used to reinforce corners or joints in steel structures.

- Rectangular gussets: These gussets are rectangular in shape and are used to reinforce joints between beams and columns.

- Circular gussets: These gussets are circular in shape and are used to reinforce joints between pipes or cylindrical sections.

- T-shaped gussets: These gussets are shaped like a “T” and are used to reinforce joints between beams and columns.

- Channel gussets: These gussets are shaped like a “C” and are used to reinforce joints between beams or columns.

- Angle gussets: These gussets are made from an angle iron and are used to reinforce joints between beams or columns.

2. What are the factors to consider when designing a gusset?

Material Properties

- Yield strength of the material

- Tensile strength of the material

- Modulus of elasticity of the material

Loading Conditions

- Type of load (axial, shear, bending)

- Magnitude of the load

- Direction of the load

Geometry of the Gusset

- Shape of the gusset

- Thickness of the gusset

- Size of the holes in the gusset

3. How do you determine the thickness of a gusset?

The thickness of a gusset is determined by calculating the forces acting on the gusset and then using the appropriate design code to determine the required thickness. The following steps are typically involved in determining the thickness of a gusset:

- Calculate the forces acting on the gusset.

- Determine the required yield strength of the gusset.

- Select a material for the gusset.

- Calculate the required thickness of the gusset using the appropriate design code.

4. What are the different methods of gusset fabrication?

The different methods of gusset fabrication include:

- Welding

- Bolting

- Riveting

The choice of fabrication method depends on the type of gusset, the material of the gusset, and the required strength of the joint.

5. What are the quality control checks that you perform on gussets?

The quality control checks that I perform on gussets include:

- Visual inspection

- Dimensional inspection

- Material testing

- Weld inspection

- Bolt inspection

These checks are performed to ensure that the gussets meet the required specifications and are of good quality.

6. What are the safety precautions that you take when working with gussets?

The safety precautions that I take when working with gussets include:

- Wearing appropriate personal protective equipment (PPE), such as safety glasses, gloves, and a hard hat.

- Using proper lifting techniques when handling gussets.

- Being aware of the potential hazards of working with gussets, such as sharp edges and heavy weights.

- Following all safety procedures and guidelines.

Taking these precautions helps to ensure that I stay safe while working with gussets.

7. What are the challenges that you have faced in your previous role as a Gusset Maker?

Some of the challenges that I have faced in my previous role as a Gusset Maker include:

- Working with tight deadlines.

- Meeting the required quality standards.

- Working with heavy and awkward materials.

- Staying up-to-date with the latest industry trends and technologies.

I have overcome these challenges by being organized, efficient, and detail-oriented. I have also taken the initiative to learn new skills and technologies.

8. What are your strengths and weaknesses as a Gusset Maker?

Strengths

- I am a highly skilled and experienced Gusset Maker with over 5 years of experience.

- I am proficient in all aspects of gusset fabrication, including welding, bolting, and riveting.

- I am a quick learner and I am always willing to take on new challenges.

- I am a team player and I am always willing to help out my colleagues.

Weaknesses

- I can sometimes be too detail-oriented, which can slow down my progress.

- I am not always the best at communicating with others, which can lead to misunderstandings.

9. Why are you interested in this Gusset Maker position?

I am interested in this Gusset Maker position because it offers me the opportunity to use my skills and experience to contribute to the success of your company. I am also excited about the opportunity to work with a team of experienced professionals and to learn from them.

10. What are your salary expectations?

My salary expectations are commensurate with my experience and qualifications. I am also willing to negotiate a salary that is fair for both parties.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Gusset Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Gusset Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Gusset Maker is responsible for the smooth operation of the gusseting machine, ensuring the production of high-quality gussets for various packaging applications.

1. Machine Operation

The Gusset Maker’s primary responsibility is to operate the gusseting machine. This involves setting up and adjusting the machine to specific product requirements, such as gusset size, material thickness, and seam type.

- Set up and adjust the gusseting machine to meet specific product specifications.

- Monitor the machine during operation, ensuring it runs smoothly and efficiently.

- Troubleshoot and resolve minor machine malfunctions, ensuring minimal downtime.

2. Gusset Production

The Gusset Maker is responsible for producing gussets that meet quality standards. This includes ensuring that the gussets are properly seamed, have the correct size and shape, and are free from defects.

- Feed material into the gusseting machine and monitor the production process.

- Inspect and sort gussets, ensuring they meet quality specifications.

- Package and label gussets for shipment or storage.

3. Quality Control

The Gusset Maker plays a crucial role in maintaining the quality of the gussets produced. This involves inspecting the gussets for defects, such as broken seams, uneven sizes, or material imperfections.

- Inspect gussets for defects, such as broken seams or uneven sizes.

- Identify and resolve quality issues, ensuring the production of high-quality gussets.

- Maintain records of quality control checks and report any quality concerns.

4. Safety and Maintenance

The Gusset Maker must adhere to safety protocols and perform routine maintenance to ensure the safe and efficient operation of the gusseting machine.

- Follow safety protocols while operating the gusseting machine.

- Perform regular maintenance and cleaning of the machine to prevent breakdowns.

- Report any safety or maintenance concerns to the supervisor.

Interview Tips

To ace the interview for a Gusset Maker position, it is essential to prepare thoroughly and showcase your skills and experience.

1. Research the Company and Position

Before the interview, research the company, its products, and the specific requirements of the Gusset Maker position. This will enable you to tailor your answers to the interviewer’s questions and demonstrate your understanding of the role.

- Visit the company’s website to learn about their products and services.

- Read industry articles and news to stay informed about the latest trends and technologies in gusset manufacturing.

- Review the job description carefully to identify the key skills and responsibilities required for the position.

2. Highlight Relevant Skills and Experience

During the interview, emphasize your skills and experience that are relevant to the Gusset Maker position. Quantify your accomplishments whenever possible to demonstrate the impact of your contributions.

- Showcase your experience in operating and maintaining gusseting machines.

- Highlight your knowledge of different types of gussets, materials, and seam types.

- Provide examples of your ability to identify and resolve quality issues.

3. Demonstrate Problem-Solving Abilities

Gusset Makers often encounter problems during the production process. In the interview, be prepared to discuss how you approach and solve problems. Provide specific examples of how you have overcome challenges in a previous role.

- Describe a situation where you identified and resolved a machine malfunction.

- Explain how you handled a production issue that affected the quality of the gussets.

- Discuss your approach to troubleshooting and problem-solving.

4. Emphasize Safety and Quality Control

Safety and quality control are paramount in the Gusset Maker role. During the interview, emphasize your commitment to safety and your understanding of quality control procedures.

- Discuss your knowledge of safety protocols and your experience following them.

- Explain how you maintain the cleanliness and proper functioning of the gusseting machine.

- Describe your approach to quality control inspections and your ability to identify defects.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Gusset Maker, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Gusset Maker positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.