Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Gypsum Calciner position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

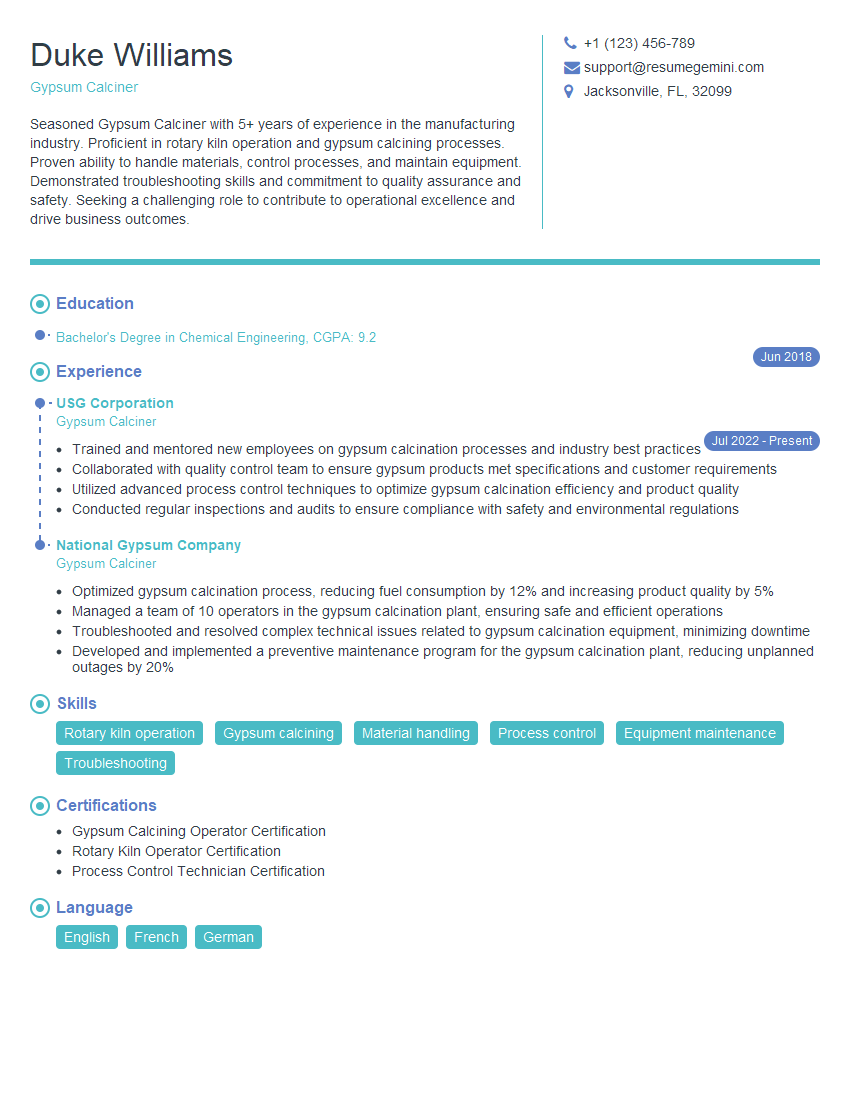

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Gypsum Calciner

1. Describe the process of gypsum calcination.

Gypsum calcination is the process of heating gypsum (calcium sulfate dihydrate, CaSO4·2H2O) to remove water and produce calcium sulfate hemihydrate (CaSO4·1/2H2O). This process is used to create plaster of Paris, a material used in construction and art.

- The process begins by grinding gypsum into a fine powder.

- The powder is then heated in a kiln or furnace to a temperature of 120-180 degrees Celsius (250-360 degrees Fahrenheit).

- At this temperature, the water molecules in the gypsum evaporate, leaving behind calcium sulfate hemihydrate.

- The calcium sulfate hemihydrate is then cooled and ground into a fine powder.

2. What are the key factors that affect the quality of calcined gypsum?

Temperature

- The temperature of the kiln or furnace is critical to the quality of the calcined gypsum.

- If the temperature is too low, the gypsum will not be fully calcined and will retain some of its water content.

- If the temperature is too high, the gypsum will be over-calcined and will lose its strength and durability.

Time

- The length of time that the gypsum is heated is also important.

- If the gypsum is heated for too short a period of time, it will not be fully calcined.

- If the gypsum is heated for too long a period of time, it will be over-calcined.

Atmosphere

- The atmosphere in the kiln or furnace can also affect the quality of the calcined gypsum.

- If the atmosphere is too moist, the gypsum will not be fully calcined.

- If the atmosphere is too dry, the gypsum will be over-calcined.

3. Describe the different types of gypsum calcining kilns.

- Rotary kilns are the most common type of gypsum calcining kiln.

- They are long, cylindrical kilns that rotate slowly as the gypsum is heated.

- Rotary kilns are efficient and can produce a high-quality product.

- Vertical kilns are another type of gypsum calcining kiln.

- They are tall, vertical kilns that are heated by burners at the bottom.

- Vertical kilns are less efficient than rotary kilns, but they can produce a higher-quality product.

- Fluidized bed calciners are a newer type of gypsum calcining kiln.

- They use a fluidized bed of sand to heat the gypsum.

- Fluidized bed calciners are very efficient and can produce a high-quality product.

4. What are the safety hazards associated with gypsum calcination?

- The primary safety hazard associated with gypsum calcination is dust exposure.

- Gypsum dust can cause respiratory problems, such as asthma and bronchitis.

- It is important to wear a respirator when working with gypsum dust.

- Other safety hazards associated with gypsum calcination include heat exposure, burns, and explosions.

- It is important to follow all safety procedures when working with gypsum calcination equipment.

5. What are the environmental impacts of gypsum calcination?

- The primary environmental impact of gypsum calcination is the release of sulfur dioxide (SO2) gas.

- SO2 gas is a major air pollutant that can contribute to acid rain.

- Gypsum calcination plants are required to install pollution control equipment to reduce SO2 emissions.

- Other environmental impacts of gypsum calcination include the release of dust and noise.

6. What are the applications of calcined gypsum?

- The primary application of calcined gypsum is as a binder in the construction industry.

- It is used in the production of plaster, drywall, and other building materials.

- Calcined gypsum is also used in the production of cement, fertilizers, and other industrial products.

7. How do you optimize the calcination process to ensure the desired product quality?

- To optimize the calcination process, it is important to control the temperature, time, and atmosphere of the kiln or furnace.

- The temperature should be high enough to fully calcine the gypsum, but not so high that it over-calcines the gypsum.

- The time should be long enough to fully calcine the gypsum, but not so long that it over-calcines the gypsum.

- The atmosphere should be dry enough to prevent the gypsum from absorbing moisture, but not so dry that it causes the gypsum to over-calcine.

8. What equipment is used in a gypsum calcining plant?

- The main equipment used in a gypsum calcining plant includes a kiln or furnace, a cooler, and a grinder.

- The kiln or furnace is used to heat the gypsum to remove the water.

- The cooler is used to cool the calcined gypsum.

- The grinder is used to grind the calcined gypsum into a powder.

9. What are the common problems that can occur during gypsum calcination?

- The most common problems that can occur during gypsum calcination include over-calcination, under-calcination, and dusting.

- Over-calcination occurs when the gypsum is heated to too high a temperature, resulting in a loss of strength and durability.

- Under-calcination occurs when the gypsum is not heated to a high enough temperature, resulting in a product that is not fully calcined.

- Dusting occurs when the calcined gypsum is not properly cooled, resulting in a product that is dusty and difficult to handle.

10. How do you troubleshoot and resolve problems in a gypsum calcining plant?

- To troubleshoot and resolve problems in a gypsum calcining plant, it is important to first identify the problem.

- Once the problem has been identified, it is important to determine the cause of the problem.

- Once the cause of the problem has been determined, it is important to develop a solution to the problem.

- The solution to the problem should be implemented and tested.

- Once the solution has been tested and proven to be effective, it should be documented.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Gypsum Calciner.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Gypsum Calciner‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Gypsum Calciners are responsible for operating and maintaining gypsum calcining equipment, ensuring efficient production of calcined gypsum and minimizing production costs. Their key responsibilities include:

1. Equipment Operation and Maintenance

Operate gypsum calciners, including setting up, adjusting, and monitoring process parameters.

- Maintain and repair gypsum calcining equipment, including kilns, crushers, and conveyors.

- Conduct routine inspections and perform necessary adjustments to ensure equipment is functioning properly.

2. Production Management

Monitor and control production processes, ensuring consistent quality and meeting production targets.

- Analyze quality control data and make adjustments to optimize calcining process.

- Implement process improvement initiatives to enhance efficiency and reduce costs.

3. Process Troubleshooting

Identify and resolve process issues, ensuring smooth and continuous production.

- Troubleshoot and fix equipment malfunctions, minimizing downtime and production losses.

- Collaborate with maintenance technicians to diagnose and repair equipment.

4. Safety and Environmental Compliance

Ensure compliance with safety regulations and environmental standards.

- Follow established safety protocols and wear appropriate personal protective equipment.

- Monitor environmental emissions and ensure compliance with regulations.

Interview Tips

To ace the interview, candidates should demonstrate a thorough understanding of gypsum calcining processes, equipment, and safety practices. Here are some interview preparation tips:

1. Research the Company and Position

Learn about the company’s history, operations, and specific role you are applying for. This will help you tailor your answers to the interviewer’s questions.

2. Practice Answering Common Interview Questions

Prepare for questions about your experience with gypsum calcining, process optimization, equipment maintenance, and safety compliance. Provide specific examples to support your answers.

3. Show Interest in the Industry

Demonstrate your passion for the gypsum industry by staying updated on industry news and trends. Discuss how you can contribute to the company’s goals in this field.

4. Highlight Your Safety Consciousness

Emphasize your commitment to safety and environmental compliance. Explain how you follow safety protocols, conduct risk assessments, and handle potential hazards.

5. Be Confident and Enthusiastic

Project confidence in your abilities and enthusiasm for the role. Communicate your willingness to learn, adapt, and contribute to the team.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Gypsum Calciner interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!