Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Gyroscopic Instrument Mechanic position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

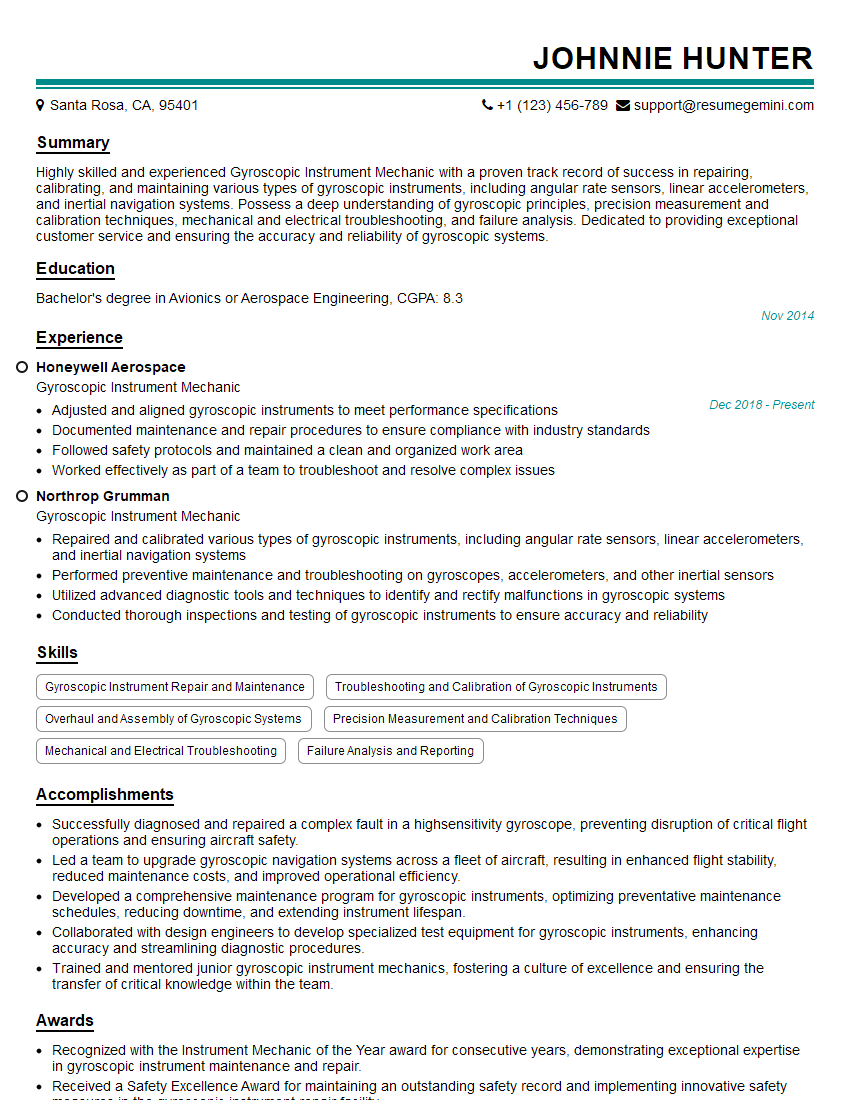

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Gyroscopic Instrument Mechanic

1. Elaborate on the procedure for maintaining and calibrating a Vertical Gyro.

- Start by visually inspecting the gyro for any external damage or leaks.

- Connect the gyro to a calibration fixture and apply power.

- Perform a series of tests to assess the gyro’s performance, including drift, sensitivity, and linearity.

- Make adjustments to the gyro’s parameters as necessary to meet the manufacturer’s specifications.

- Document the calibration results and store the gyro in a controlled environment.

2. Explain the principles of operation of a Rate Integrating Gyro.

- A Rate Integrating Gyro (RIG) measures angular velocity and integrates it over time to provide angular displacement.

- The RIG consists of a spinning mass and a pick-off system that senses the Coriolis force acting on the mass.

- The Coriolis force is proportional to the angular velocity, and the pick-off system converts this force into an electrical signal.

- The electrical signal is then integrated to provide angular displacement.

3. Describe the purpose and construction of a Turn and Slip Indicator.

- A Turn and Slip Indicator (TSI) is used to provide aircraft pilots with information about the aircraft’s turn rate and slip angle.

- The TSI consists of a vertical glass tube filled with fluid and a small ball that is free to move within the tube.

- When the aircraft is in a turn, the ball will move to the outside of the turn due to centrifugal force.

- When the aircraft is in a slip, the ball will move down the tube due to the force of gravity.

4. Discuss the maintenance procedures for a Directional Gyro.

- Inspect the gyro for any visible damage or leaks.

- Lubricate the gyro’s bearings according to the manufacturer’s instructions.

- Check the gyro’s electrical connections and ensure that they are tight.

- Perform a pre-flight check of the gyro to ensure that it is operating correctly.

- Calibrate the gyro regularly to ensure that it is accurate.

5. Explain the troubleshooting procedure for a gyroscope that is exhibiting drift.

- Inspect the gyroscope for any obvious damage or leaks.

- Check the gyroscope’s electrical connections and ensure that they are tight.

- Lubricate the gyroscope’s bearings according to the manufacturer’s instructions.

- Calibrate the gyroscope according to the manufacturer’s instructions.

- If the drift persists, the gyroscope may need to be replaced.

6. Describe the different types of gyroscopic instruments used in aviation.

- Vertical Gyros

- Rate Integrating Gyros

- Turn and Slip Indicators

- Directional Gyros

- Attitude and Heading Reference Systems (AHRS)

- Inertial Navigation Systems (INS)

7. What is the purpose of a Schuler loop in an Inertial Navigation System (INS)?

The purpose of a Schuler loop in an Inertial Navigation System (INS) is to filter out the low-frequency errors that are introduced by the Earth’s rotation.

8. Explain the principle of operation of a laser gyroscope.

- A laser gyroscope measures angular velocity by detecting the Sagnac effect.

- The Sagnac effect is the phenomenon of the phase shift of light that is traveling in a rotating frame of reference.

- The amount of phase shift is proportional to the angular velocity of the rotating frame.

9. Describe the advantages and disadvantages of using fiber optic gyroscopes (FOGs).

- FOGs are not subject to drift.

- FOGs are very small and lightweight.

- FOGs have a wide dynamic range.

- FOGs are more expensive than mechanical gyros.

- FOGs are more sensitive to temperature changes.

Advantages

Disadvantages

10. What are the latest trends in gyroscopic technology?

- The development of MEMS (Micro-Electro-Mechanical Systems) gyroscopes.

- The use of fiber optic gyroscopes (FOGs) in high-performance applications.

- The integration of gyroscopes with other sensors, such as accelerometers and magnetometers, to create inertial navigation systems (INSs).

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Gyroscopic Instrument Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Gyroscopic Instrument Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Gyroscopic Instrument Mechanics are responsible for the installation, maintenance, and repair of gyroscopic instruments, which are used for navigation and guidance in various industries such as aviation, marine, and defense.

1. Installation and Commissioning

Install and commission gyroscopic instruments according to manufacturer’s specifications.

- Mount and align instruments using precision tools and techniques.

- Connect and test electrical and mechanical systems.

2. Maintenance and Inspection

Conduct regular maintenance and inspections to ensure the proper functioning of gyroscopic instruments.

- Clean and lubricate moving parts.

- Check for wear and tear, and replace components as necessary.

- Perform calibration and adjustments to maintain accuracy.

3. Troubleshooting and Repair

Troubleshoot and repair malfunctions in gyroscopic instruments.

- Diagnose problems using specialized test equipment.

- Repair or replace faulty components, ensuring the instrument’s functionality.

- Document repairs and maintenance activities.

4. Safety and Compliance

Adhere to safety regulations and industry standards in all aspects of work.

- Use personal protective equipment and follow safe work practices.

- Ensure compliance with relevant regulations and certifications.

Interview Tips

To ace an interview for a Gyroscopic Instrument Mechanic position, it is crucial to be well-prepared. Here are some tips to help you succeed:

1. Research the Company and Position

Research the company’s background, industry, and specific requirements for the Gyroscopic Instrument Mechanic role. This will help you tailor your answers to demonstrate your understanding of the job and fit with the company.

- Visit the company’s website and social media pages.

- Read articles and reviews about the company.

- Prepare questions specific to the role and company.

2. Highlight Your Skills and Experience

Emphasize your relevant skills and experience in gyroscopic instrument installation, maintenance, and repair. Quantify your accomplishments using specific examples and metrics.

- Highlight your hands-on experience with gyroscopic instruments.

- Discuss your troubleshooting and repair abilities.

- Provide examples of projects where you successfully installed or repaired gyroscopic instruments.

3. Practice Your Interview Answers

Prepare your answers to common interview questions and practice delivering them confidently. Use the STAR method (Situation, Task, Action, Result) to provide structured and detailed responses.

- Anticipate questions about your technical abilities, troubleshooting skills, and safety protocols.

- Practice answering questions highlighting your teamwork and communication skills.

- Prepare a short elevator pitch about your qualifications.

4. Be Enthusiastic and Professional

Convey your enthusiasm for the field and demonstrate your commitment to delivering high-quality work. Maintain a professional demeanor throughout the interview.

- Dress appropriately and arrive on time for the interview.

- Be polite and respectful to the interviewers.

- Ask thoughtful questions to show your engagement and interest.

5. Follow Up

After the interview, send a thank-you note to the interviewers expressing your appreciation for the opportunity. This is a chance to reiterate your interest and any additional points you may have forgotten to mention.

- Thank the interviewers for their time and consideration.

- Reiterate your interest in the position.

- Mention any specific aspects of the interview that you found particularly relevant.

Next Step:

Now that you’re armed with the knowledge of Gyroscopic Instrument Mechanic interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Gyroscopic Instrument Mechanic positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini