Are you gearing up for an interview for a Hack Saw Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Hack Saw Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

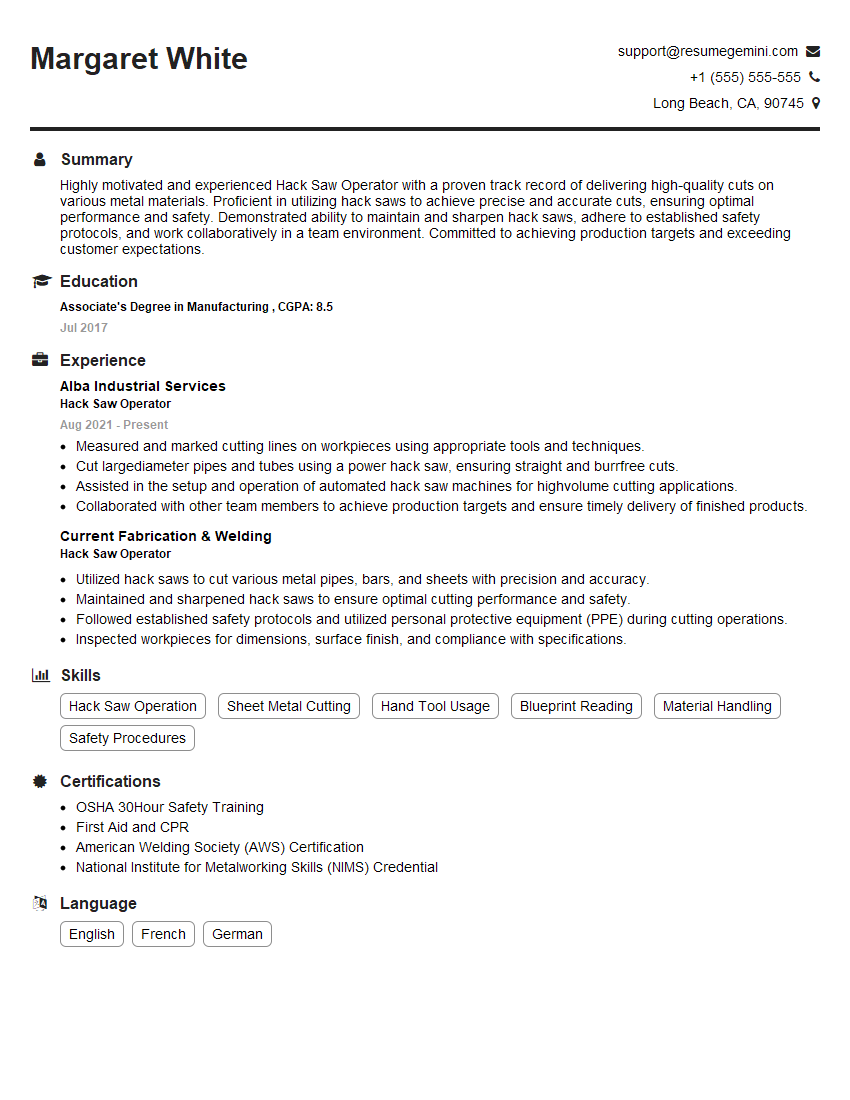

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hack Saw Operator

1. How do you ensure accuracy and precision in your hack sawing operations?

Experience has taught me the importance of precision as a Hack Saw Operator. I always make sure to have a solid understanding of the blueprints and cutting specifications before I begin working on a project. Moreover, I am skilled in making accurate measurements and checking my work regularly to avoid errors.

- Utilizing high-quality hack saws and blades to minimize deviations.

- Establishing and aligning workpieces securely to ensure straight and accurate cuts.

- Applying proper blade tension and cutting speed to achieve desired cut quality.

2. Describe the different types of hack saw blades and their applications.

High-carbon steel blades

- Durable and suitable for general-purpose cutting.

- Ideal for cutting ferrous metals like steel and iron.

Bi-metal blades

- Combination of high-carbon steel and high-speed steel.

- Strong and flexible, suitable for cutting hard materials.

Hacksaw frames

- Adjustable frames allow for variable blade lengths and angles.

- Ensures the correct blade tension for precise cutting.

3. What are the safety precautions you observe when operating a hack saw?

Safety is paramount when operating a hack saw. I adhere to these precautions:

- Wearing proper safety gear, including gloves, safety glasses, and earplugs.

- Inspecting the hack saw and its components thoroughly before use.

- Ensuring the workpiece is securely clamped to prevent movement.

- Using a light cutting pressure to avoid blade breakage.

- Being aware of potential hazards and maintaining a clean and organized work area.

4. How do you maintain and care for hack saw blades?

Proper maintenance of hack saw blades is crucial for optimal performance. I follow these practices:

- Cleaning blades regularly to remove debris and extend their lifespan.

- Inspecting blades for any damage or wear and replacing them promptly if necessary.

- Lubricating blades with a light oil to minimize friction and improve cutting efficiency.

- Storing blades in a dry and moisture-free environment to prevent rust and corrosion.

5. How do you troubleshoot common problems encountered while using a hack saw?

Troubleshooting is an essential skill in hack saw operation. I am familiar with common issues and their solutions:

Blade breakage

- Check for proper blade tension and workpiece clamping.

- Inspect the blade for damage or wear and replace if needed.

Inaccurate cuts

- Ensure the workpiece is securely clamped and the blade is perpendicular to the cutting surface.

- Check for blade alignment and adjust the frame if necessary.

Difficult cutting

- Use a sharper blade or increase cutting pressure.

- Lubricate the blade to reduce friction.

6. What are the different techniques for using a hack saw?

I am proficient in various hack sawing techniques to achieve different results:

Straight cutting

- Holding the saw perpendicular to the workpiece and applying even pressure.

- Using a miter box for precise angle cuts.

Contour cutting

- Guiding the saw along a curved or irregular shape.

- Using a coping saw for intricate cuts.

Flush cutting

- Cutting close to a surface or another object.

- Using a hacksaw with a flush-cut blade.

7. How do you select the appropriate hack saw blade for different materials?

Choosing the right blade is crucial for efficient cutting. I consider the following factors:

Material hardness

- Harder materials require blades with higher tooth counts and harder alloys.

- Softer materials can be cut with blades having lower tooth counts and softer alloys.

Material thickness

- Thicker materials need blades with coarser tooth pitches.

- Thinner materials require finer tooth pitches.

Desired cut quality

- For smooth and precise cuts, use blades with higher tooth counts.

- For faster and less precise cuts, blades with lower tooth counts are suitable.

8. What are your techniques for cutting different types of materials with a hack saw?

Cutting ferrous metals

- Use high-carbon steel or bi-metal blades with 14-18 TPI.

- Apply moderate pressure and keep the blade lubricated.

Cutting non-ferrous metals

- Use bi-metal or high-speed steel blades with 24-32 TPI.

- Apply less pressure and avoid overheating the blade.

Cutting plastics

- Use blades with finer tooth pitches (32-44 TPI).

- Apply light pressure and use a lubricant to prevent melting.

9. How do you measure and mark workpieces for hack sawing?

Accurate measurements and markings are essential for precise cutting. My process involves:

- Using a measuring tape or ruler to determine the desired length or shape.

- Marking the workpiece with a pencil, scribe, or soapstone.

- Ensuring the marks are clear and visible during the cutting process.

10. How do you adjust the tension on a hack saw?

Correct blade tension is crucial for efficient and safe cutting:

- Locate the tension adjustment screw or knob on the hacksaw frame.

- Tighten the screw or knob gradually while holding the blade in place.

- Check the tension by gently pulling on the blade. It should have a slight flex but not be too loose or too tight.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hack Saw Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hack Saw Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Hack Saw Operator is responsible for cutting and shaping metal using a hack saw. They must be able to read and interpret blueprints, as well as operate a variety of power tools.

1. Cutting and Shaping Metal

Using a hack saw, the operator cuts and shapes metal to create various products. They must be able to accurately follow blueprints and use the correct tools for the job.

- Use a hack saw to cut metal to specific lengths and shapes.

- Operate a variety of power tools, such as drill presses, grinders, and lathes.

2. Reading and Interpreting Blueprints

The operator must be able to read and interpret blueprints in order to accurately cut and shape metal. They must be able to understand the symbols and dimensions used on blueprints.

- Read and interpret blueprints to determine the dimensions and shapes of the parts to be cut.

- Lay out the metal to be cut according to the blueprints.

3. Maintaining Equipment

The operator is responsible for maintaining the hack saw and other equipment used in the job. They must be able to identify and troubleshoot problems, and make necessary repairs.

- Clean and lubricate the hack saw and other equipment.

- Inspect the equipment for damage and make necessary repairs.

4. Safety

The operator must follow all safety procedures when operating the hack saw and other equipment. They must wear appropriate safety gear, such as eye protection and gloves.

- Follow all safety procedures when operating the hack saw and other equipment.

- Wear appropriate safety gear, such as eye protection and gloves.

Interview Tips

Here are some tips for acing an interview for a Hack Saw Operator position:

1. Be prepared to answer questions about your experience with hack saws and other power tools.

You should be able to discuss your skills in cutting and shaping metal, as well as your experience with reading and interpreting blueprints.

- Practice answering questions about your experience with hack saws and other power tools.

- Be prepared to discuss your skills in cutting and shaping metal, as well as your experience with reading and interpreting blueprints.

2. Be familiar with the safety procedures for operating hack saws and other power tools.

You should be able to discuss the importance of wearing appropriate safety gear and following all safety procedures.

- Read the safety manual for the hack saw and other power tools that you will be using.

- Be prepared to discuss the importance of wearing appropriate safety gear and following all safety procedures.

3. Be able to work independently and as part of a team.

You should be able to work independently to complete your tasks, but you should also be able to work as part of a team to achieve the overall goals of the project.

- Give examples of your experience working independently and as part of a team.

- Discuss how you can contribute to the overall goals of the project.

4. Be enthusiastic and motivated.

You should be able to show the interviewer that you are enthusiastic about the position and that you are motivated to learn and grow.

- Express your enthusiasm for the position and your desire to learn and grow.

- Discuss your career goals and how this position can help you achieve them.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Hack Saw Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!