Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Ham Curer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Ham Curer so you can tailor your answers to impress potential employers.

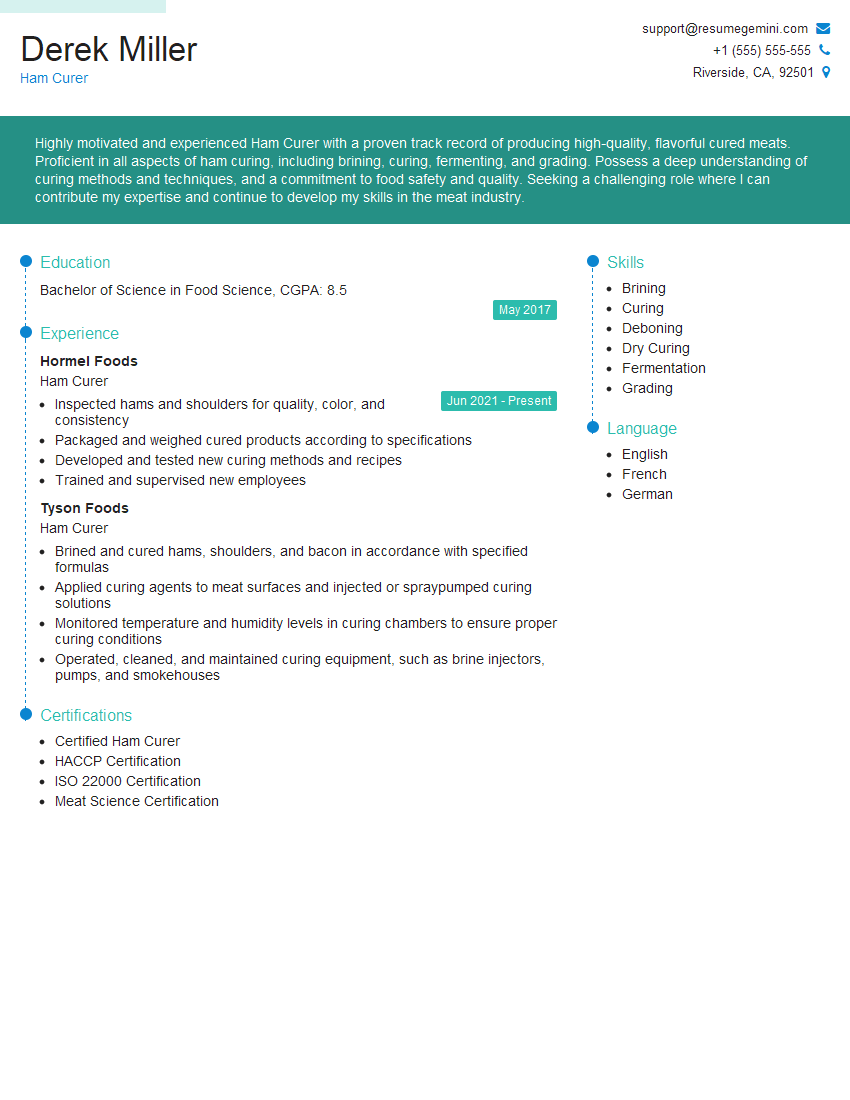

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ham Curer

1. Describe the process of dry curing ham, including the different stages and techniques involved?

Dry curing ham involves a series of stages to preserve and enhance the flavor of the ham:

- Selecting the ham: The process begins with selecting high-quality pork hams, ensuring they have the right size, shape, and fat content.

- Pre-salting: The selected hams are pre-salted to prepare them for the curing process. They are rubbed with coarse salt, which helps to draw out excess moisture.

- Dry curing: The hams are then hung in a controlled environment and cured in a cool, humid atmosphere. The salt draws moisture out of the ham, while the cool and humid conditions facilitate the development of beneficial bacteria.

- Washing and drying: After the desired saltiness and texture are achieved, the hams are washed to remove excess salt and then hung to dry.

- Aging: The final stage involves aging the hams under strictly controlled conditions. This allows for further moisture loss, flavor development, and texture improvement.

2. What are the critical factors to consider when selecting a ham for dry curing?

- Size and shape: Selecting hams with uniform size and shape helps ensure consistent curing and flavor development.

- Fat content: The ideal ham for curing should have a balance of lean meat and fat. Too much fat can result in an overly greasy finished product.

- Quality: High-quality hams from healthy animals are essential for producing a premium dry-cured product.

- Freshness: Fresh hams are preferred for curing, as older hams may have undergone some deterioration.

3. How do you determine the proper amount of salt to use in the curing process?

The amount of salt used in dry curing is crucial to ensure proper preservation and flavor development. Factors to consider include:

- Ham weight: The weight of the ham determines the amount of salt required.

- Desired saltiness: The desired level of saltiness in the finished product.

- Curing time: A longer curing time requires a higher salt concentration to ensure proper preservation.

- Climate: The climate in which the ham is cured also plays a role, with drier climates requiring more salt.

4. How do you monitor and control the temperature and humidity during the curing process?

- Temperature: The curing environment should be maintained at a cool and consistent temperature, typically between 35-45°F (2-7°C). Fluctuating temperatures can adversely affect the curing process.

- Humidity: Humidity control is equally important, with an ideal range of 75-85%. High humidity prevents excessive moisture loss and promotes bacterial growth, while low humidity can result in a dry and tough product.

- Monitoring: Regular monitoring of temperature and humidity using thermometers and hygrometers is essential to ensure optimal conditions.

5. What are the signs of spoilage in dry-cured ham?

- Slimy or sticky surface: A slimy or sticky surface can indicate bacterial growth.

- Mold: The presence of mold, especially white or green mold, is a sign of spoilage.

- Off-odor: An unpleasant or sour odor can indicate spoilage.

- Discoloration: Changes in the ham’s color, such as darkening or discoloration, can indicate spoilage.

- Rancid taste: If the ham has a rancid or bitter taste, it has likely spoiled.

6. Describe the different types of equipment used in dry curing ham and their functions?

- Curing chamber: A controlled environment that maintains the optimal temperature and humidity for curing.

- Thermometers and hygrometers: Used to monitor and control temperature and humidity levels.

- Salt boxes or bins: Containers for storing and applying curing salt.

- Hanging racks: Racks for suspending hams during curing and aging.

- Weighing scales: For measuring hams and determining salt dosage.

7. What is the difference between dry curing and wet curing ham?

- Dry curing: Involves curing the ham with only salt and other dry ingredients, drawing moisture out of the ham.

- Wet curing: Involves submerging the ham in a brine solution, allowing the salt and other ingredients to penetrate the meat.

- Results: Dry-cured hams tend to be firmer, have a more intense flavor, and a longer shelf life, while wet-cured hams are often milder and juicier.

8. What are the challenges involved in dry curing ham?

- Temperature and humidity control: Maintaining the optimal curing environment is crucial, and fluctuations can affect the quality of the final product.

- Monitoring spoilage: Careful attention is needed to prevent spoilage during the extended curing and aging process.

- Salt penetration: Ensuring even salt penetration is essential to prevent inconsistencies in flavor and texture.

- Labor-intensive: Dry curing ham is a labor-intensive process, requiring regular handling and monitoring.

9. How do you ensure food safety and quality in the dry curing process?

- Sanitation: Maintaining a clean and hygienic work environment is paramount.

- Temperature control: Proper temperature management inhibits bacterial growth.

- Salt concentration: Adequate salt levels prevent spoilage.

- Regular inspections: Frequent visual and sensory inspections are essential to detect any signs of spoilage.

- Compliance: Adherence to food safety regulations and industry best practices ensures consistent quality.

10. Describe the aging process of dry-cured ham and how it contributes to its flavor and texture?

- Enzymatic breakdown: During aging, enzymes naturally present in the ham break down proteins and fats, contributing to flavor development.

- Moisture loss: As the ham ages, it gradually loses moisture, resulting in a more concentrated flavor and a firmer texture.

- Flavor development: The extended aging period allows for complex flavors to develop, including nutty, umami, and sweet notes.

- Optimal aging time: The ideal aging time varies depending on factors such as the size of the ham and the desired flavor profile.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ham Curer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ham Curer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Ham Curer is responsible for the entire ham curing process, from receiving the meat to packaging the finished product. They work in a fast-paced environment, and must be able to handle multiple tasks simultaneously.

1. Receiving and Inspecting Meat

The Ham Curer begins by receiving and inspecting the meat. They check the meat for any damage or defects, and weigh it to ensure that it meets the specifications.

- Ensuring that the meat meets the required quality standards.

- Verifying the weight and quantity of the meat received.

2. Preparing the Brine

The Ham Curer then prepares the brine. The brine is a mixture of water, salt, sugar, and spices. The Ham Curer must carefully measure the ingredients and mix them together according to the recipe.

- Calculating the correct proportions of ingredients for the brine.

- Mixing the brine thoroughly to ensure even distribution of flavors.

3. Injecting the Meat

The Ham Curer then injects the meat with the brine. This helps to evenly distribute the flavor throughout the meat.

- Using specialized equipment to inject the brine into the meat.

- Ensuring that the meat is evenly injected to achieve desired flavor.

4. Curing the Meat

The Ham Curer then cures the meat. The meat is placed in a curing chamber and left to cure for a period of time. The curing time will vary depending on the type of ham being produced.

- Monitoring the curing process to ensure optimal conditions.

- Adjusting temperature, humidity, and other factors to achieve the desired cure.

5. Smoking the Meat

The Ham Curer then smokes the meat. The meat is placed in a smokehouse and smoked for a period of time. The smoking process helps to add flavor and color to the meat.

- Operating and monitoring the smokehouse to maintain desired temperature and smoke levels.

- Ensuring the meat is evenly smoked to achieve the required flavor profile.

6. Packaging the Meat

The Ham Curer then packages the meat. The meat is vacuum-sealed and labeled. The Ham Curer must carefully follow the packaging specifications to ensure that the meat is properly preserved.

- Selecting appropriate packaging materials to maintain the quality of the meat.

- Labeling the packages with accurate information, including product name, ingredients, and expiration date.

Interview Tips

Preparing for an interview can be nerve-wracking, but there are a few things you can do to increase your chances of success. The best way to prepare is to research the company and the position, practice answering common interview questions, and dress professionally.

1. Research the Company and the Position

Take some time to learn about the company’s history, mission, and values. This will help you understand the company’s culture and what they are looking for in a new hire.

- Visit the company’s website and social media pages.

- Read news articles and press releases about the company.

- Talk to people who work at the company.

2. Practice Answering Common Interview Questions

There are a few common interview questions that you are likely to be asked. It is helpful to practice answering these questions in advance so that you can feel confident and articulate during the interview.

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What are your salary expectations?

3. Dress Professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the office environment.

- For men, a suit or sport coat with dress pants and a tie is a good choice.

- For women, a dress, skirt and blouse, or pantsuit is a good choice.

- Make sure your shoes are clean and polished.

4. Arrive on Time

Punctuality is important for any interview, but it is especially important for a Ham Curer interview. This is because the Ham Curer is responsible for a lot of perishable meat, and they need to be able to start work on time every day.

- Give yourself plenty of time to get to the interview.

- If you are running late, call the interviewer and let them know.

5. Be Yourself!

The most important thing is to be yourself during the interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not.

- Be honest about your experience and qualifications.

- Be enthusiastic about the position.

- Be confident in your abilities.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Ham Curer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Ham Curer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.