Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Hand Buffer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

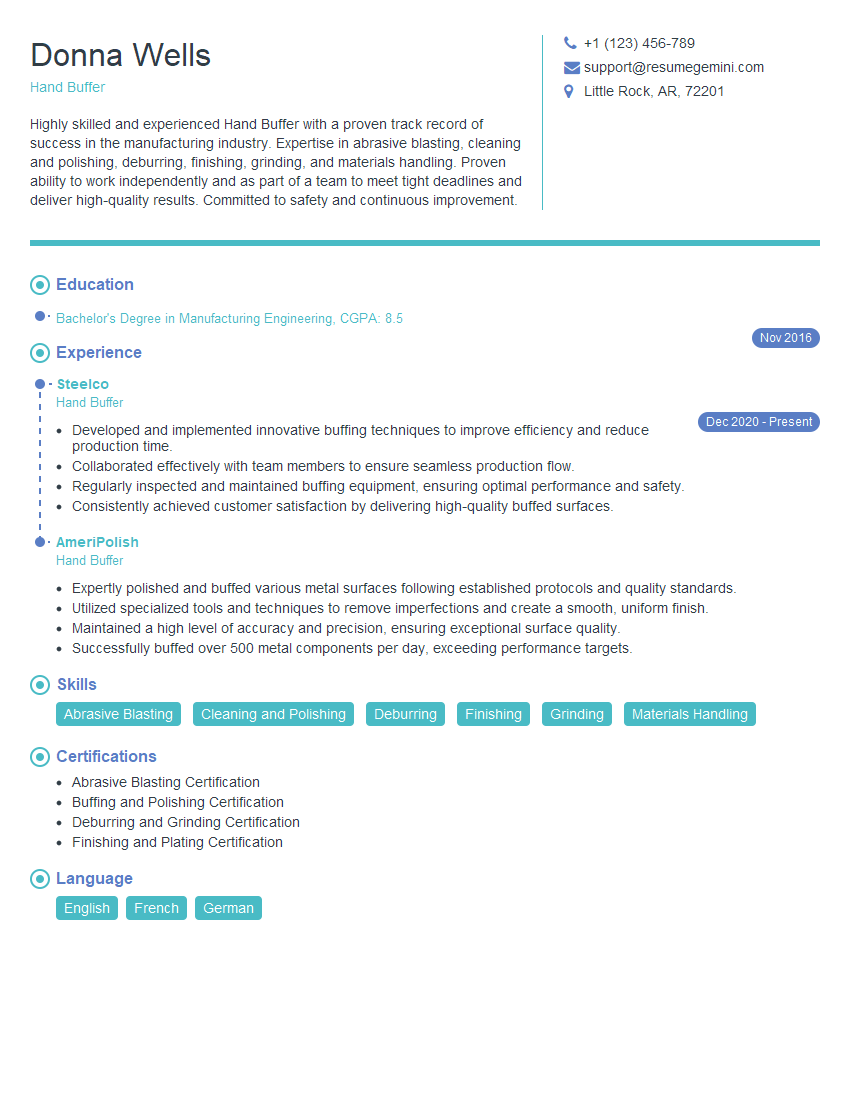

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hand Buffer

1. What are the different types of abrasives used for hand buffing?

- Natural abrasives: These include Tripoli, emery, and pumice.

- Synthetic abrasives: These include silicon carbide, aluminum oxide, and zirconium oxide.

2. How do you choose the right abrasive for a particular job?

- Consider the material being buffed.

- Determine the desired finish.

- Select an abrasive that is compatible with the buffing wheel.

3. What are the different types of buffing wheels?

- Loose cotton wheels

- Sewn cotton wheels

- Sisal wheels

- Felt wheels

- Brush wheels

4. How do you prepare a buffing wheel for use?

- Mount the wheel on the buffing machine.

- Apply a small amount of buffing compound to the wheel.

- Break in the wheel by running it at a low speed for a few minutes.

5. What is the correct technique for hand buffing?

- Hold the workpiece firmly against the buffing wheel.

- Move the workpiece in a smooth, circular motion.

- Apply even pressure to the workpiece.

6. How do you know when a workpiece is properly buffed?

- The workpiece will have a uniform finish.

- The surface of the workpiece will be free of scratches or blemishes.

- The workpiece will have the desired luster.

7. What are the safety precautions that should be taken when hand buffing?

- Wear safety glasses.

- Wear a dust mask.

- Keep your hands away from the buffing wheel.

- Do not buff objects that are too large or heavy.

8. What are the common mistakes that hand buffers make?

- Using the wrong abrasive.

- Using too much pressure.

- Moving the workpiece too quickly.

- Not breaking in the buffing wheel properly.

9. What are the different applications for hand buffing?

- Removing scratches and blemishes from metal surfaces.

- Polishing metal surfaces to a high luster.

- Cleaning and polishing jewelry.

- Buffing wood surfaces.

10. What are the advantages of hand buffing over machine buffing?

- Hand buffing is more precise.

- Hand buffing can be used to buff objects of any size or shape.

- Hand buffing is less likely to damage delicate surfaces.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hand Buffer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hand Buffer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Hand buffers are responsible for the manual buffing and polishing of various metal and non-metal surfaces to achieve a desired finish. Key responsibilities include:

1. Surface Preparation

Preparing surfaces by cleaning, sanding, or degreasing to ensure proper adhesion.

- Inspecting surfaces for defects or imperfections.

- Using hand tools or machines to remove dirt, rust, or other contaminants.

2. Buffing and Polishing

Using buffing wheels, compounds, and abrasives to create a smooth, shiny, or reflective finish.

- Selecting the appropriate buffing wheel and abrasive for the desired finish.

- Applying compounds or abrasives to the buffing wheel.

- Buffing or polishing the surface in a controlled manner to achieve the desired result.

3. Maintaining Equipment

Maintaining buffing wheels, machines, and tools to ensure optimal performance and safety.

- Cleaning and dressing buffing wheels regularly.

- Inspecting machines for wear and tear.

- Replacing or repairing worn or damaged parts.

4. Safety Compliance

Adhering to safety protocols and using personal protective equipment (PPE) to minimize risks.

- Wearing gloves, safety glasses, and respirators when necessary.

- Following proper handling and storage procedures for hazardous materials.

- Maintaining a clean and organized work area.

- Understanding and complying with all relevant safety regulations.

Interview Tips

To ace an interview for a Hand Buffer position, candidates should prepare thoroughly and present themselves professionally. Here are some essential interview tips:

1. Research the Company and Role

Familiarize yourself with the company’s background, industry, and the specific requirements of the Hand Buffer role. This demonstrates your interest and understanding of the position.

- Visit the company’s website and social media pages.

- Read industry news and publications.

- Review the job description thoroughly.

- Prepare questions to ask the interviewer about the company and the role.

2. Highlight Relevant Skills and Experience

Emphasize your hands-on experience in buffing and polishing, as well as any relevant skills such as surface preparation, equipment maintenance, and safety compliance. Quantify your accomplishments with specific examples and metrics whenever possible.

- Provide details about previous projects or tasks where you successfully buffed and polished various surfaces.

- Describe your experience with different buffing wheels, compounds, and abrasives.

- Share examples of how you have maintained and repaired buffing equipment.

- Explain your understanding of safety protocols and PPE usage.

3. Demonstrate Attention to Detail

Hand Buffering requires precision and attention to detail. During the interview, emphasize your meticulous nature and ability to focus on the task at hand. Provide examples where you have successfully completed complex or intricate projects.

- Describe a project where you had to achieve a specific surface finish or texture.

- Explain how you ensured the quality and consistency of your work.

- Share an example where you identified and corrected a surface defect before it became a major problem.

4. Be Enthusiastic and Motivated

Conveying your enthusiasm and motivation for the role can set you apart from other candidates. Explain why you are interested in Hand Buffing and how it aligns with your career goals. Share examples of your commitment to excellence and your drive to produce high-quality work.

- Explain what attracts you to the Hand Buffering profession.

- Describe your long-term career aspirations.

- Share an example of a time when you went above and beyond to complete a task.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Hand Buffer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.