Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Hand Candle Molder position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

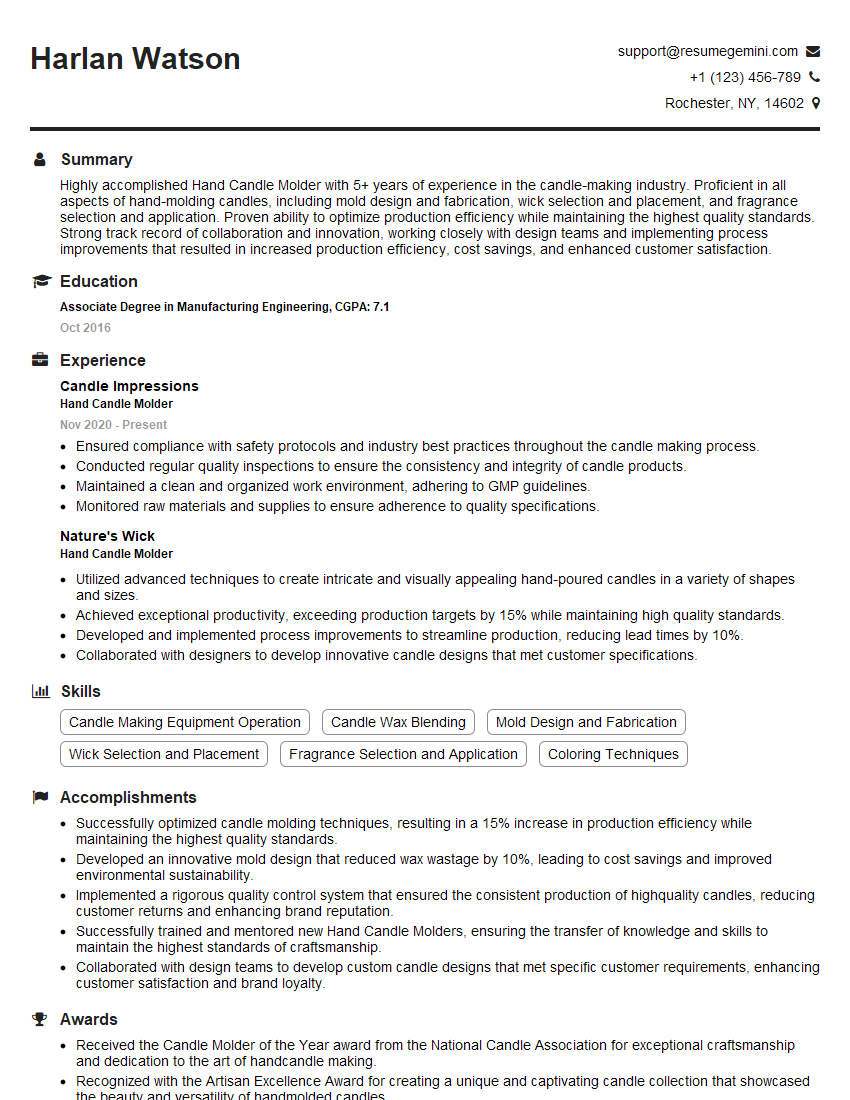

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hand Candle Molder

1. Describe the process of hand molding candles?

The process of hand molding candles involves several steps:

- Preparing the mold: The mold is cleaned and prepared by applying a release agent to prevent the candle from sticking.

- Melting the wax: The candle wax is melted in a double boiler or a dedicated wax melter to the desired temperature.

- Adding fragrance and color: Fragrance oils and colorants are added to the melted wax and mixed thoroughly.

- Pouring the wax: The melted wax is carefully poured into the prepared mold, filling it to the desired level.

- Cooling and setting: The mold is left to cool at room temperature or in a cool place for several hours, allowing the wax to solidify and set.

- Unmolding: Once the candle has set, it is gently removed from the mold by inverting it and tapping on the sides.

- Trimming and finishing: The candle is trimmed to remove any excess wick and smoothed to ensure a clean and professional finish.

2. What types of wax are commonly used in hand molding?

- Soy wax: Made from soybeans, soy wax is a popular choice due to its natural and eco-friendly properties.

- Paraffin wax: A petroleum-based wax that is widely used in candle making due to its low cost and high melting point.

- Beeswax: A natural wax produced by honeybees, beeswax is known for its rich, golden color and pleasant aroma.

- Gel wax: A synthetic wax that creates a clear, jelly-like appearance in candles.

- Palm wax: Derived from palm oil, palm wax is a sustainable and renewable option with a high melting point.

3. What are the different types of candle molds available?

- Single-cavity molds: Designed to create individual candles of various shapes and sizes.

- Multi-cavity molds: Allow for the production of multiple candles simultaneously, increasing efficiency.

- Silicone molds: Flexible and durable, silicone molds are easy to use and provide intricate details.

- Plastic molds: Typically used for larger candles, plastic molds offer a range of shapes and textures.

- Metal molds: Strong and long-lasting, metal molds produce candles with a smooth and polished finish.

4. How do you determine the correct wick size for a hand-molded candle?

- Candle diameter: The diameter of the candle influences the wick size, with wider candles requiring larger wicks.

- Wax type: Different waxes have varying burn rates, affecting the wick size selection.

- Fragrance load: Candles with high fragrance loads may require larger wicks to ensure proper combustion.

- Burn time: The desired burn time of the candle helps determine the appropriate wick size.

- Testing: Conducting burn tests with different wick sizes is essential to find the optimal size for the best burn quality.

5. How do you ensure the safety of hand-molded candles?

- Selecting high-quality materials: Using reputable suppliers and choosing non-toxic waxes and fragrances.

- Proper wicking: Determining the correct wick size and ensuring it is centered within the candle for even burning.

- Burn instructions and warnings: Providing clear instructions and safety warnings on candle labels to prevent accidents.

- Testing and quality control: Conducting thorough testing of candles to ensure they meet safety standards and burn consistently.

- Compliance with regulations: Adhering to industry regulations and safety guidelines to guarantee the safety of the products.

6. What techniques can be used to create unique and decorative hand-molded candles?

- Layering: Pouring different colors or wax types in layers to create a multi-toned effect.

- Embedding: Incorporating objects such as flowers, herbs, or crystals into the candle for added visual appeal.

- Carving: Using tools or heat to create intricate designs or patterns on the surface of the candle.

- Molding: Using custom-made or found objects as molds to create unique shapes and forms.

- Texturing: Employing techniques like marbling or stamping to add texture and depth to the candle.

7. How do you troubleshoot common problems that arise during hand candle molding?

Sinkholes:

- Pouring the wax at too high a temperature.

- Cooling the candle too quickly.

- Using the wrong wick size.

Tunneling:

- Using too small a wick.

- Adding too much fragrance.

- Cooling the candle too slowly.

Frosting:

- Using paraffin wax that is not fully refined.

- Exposing the candle to extreme temperature fluctuations.

- Cooling the candle too quickly.

8. How do you stay up-to-date with the latest trends and techniques in hand candle molding?

- Attending industry events and workshops.

- Subscribing to trade publications and blogs.

- Networking with other candle makers.

- Experimenting with new materials and techniques.

- Conducting research and development.

9. Describe your experience in working with different types of candle waxes.

- Soy wax: Experience in handling and melting soy wax, achieving optimal pouring temperatures, and troubleshooting common issues.

- Paraffin wax: Knowledge of paraffin wax properties, including melting points and hardening times, to ensure proper candle formation.

- Beeswax: Familiarity with the unique characteristics of beeswax, such as its natural honey scent and slow burning time.

- Gel wax: Expertise in creating transparent and decorative gel candles, understanding their specific melting and pouring techniques.

- Palm wax: Experience in working with sustainable palm wax, managing its higher melting point and ensuring proper wicking.

10. How do you ensure consistency in the quality of your hand-molded candles?

- Establishing standardized processes and procedures.

- Using high-quality materials and reliable suppliers.

- Conducting thorough testing and quality control measures.

- Maintaining accurate records of production parameters.

- Receiving regular feedback from customers and making improvements based on their input.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hand Candle Molder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hand Candle Molder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Hand Candle Molders are responsible for crafting high-quality candles using traditional hand-pouring techniques.

1. Candle Production

The primary duty is to skillfully hand pour molten candle wax into molds to create candles of various sizes, shapes, and designs.

- Precisely measure and weigh candle wax and fragrances according to specified formulas.

- Heat the wax to the optimal temperature and add colorants or scents as required.

2. Wicking and Curing

Ensure proper wick placement and wick centering within the mold before pouring the wax.

- Carefully trim wicks to the correct length, ensuring optimal burning and safety.

- Monitor the curing process to ensure the candles set properly and achieve desired hardness.

3. Quality Control

Inspect candles for defects, including uneven surfaces, air bubbles, or improper wick placement.

- Adhere to strict quality standards and correct any imperfections before packaging.

- Maintain a clean and organized work area, following safety protocols and good manufacturing practices.

4. Equipment Maintenance

Clean and maintain candle-making equipment, including molds, pouring pots, and wick centering tools.

- Ensure equipment is in proper working order to prevent production delays or safety hazards.

- Calibrate and adjust equipment as needed, ensuring accuracy and efficiency.

Interview Preparation Tips

Preparing thoroughly for an interview can significantly increase your chances of making a positive impression and securing the job offer.

1. Research the Company and the Role

Before the interview, delve into the company’s website, social media pages, and industry publications to gain insights into their culture, values, and recent developments.

- Tailor your resume and cover letter to highlight skills and experiences that align with the specific job requirements.

2. Practice Common Interview Questions

Anticipate common interview questions such as “Tell me about yourself” or “Why are you interested in this role?”

- Craft concise and compelling answers that showcase your qualifications and enthusiasm for the position.

3. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview demonstrates your engagement and interest.

- Inquire about the company’s growth plans, industry trends, or the specific challenges you may face in the role.

4. Dress Professionally and Arrive on Time

First impressions matter. Dress professionally and arrive for your interview on time, showing respect for the interviewer’s time and schedule.

- Consider the company culture and dress accordingly, aiming for a polished and appropriate appearance.

5. Be Yourself and Stay Positive

Throughout the interview, be authentic and genuine. Employers value candidates who are confident in their abilities and passionate about the work.

- Stay positive and enthusiastic, even if you encounter unexpected questions or challenges.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Hand Candle Molder, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Hand Candle Molder positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.