Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Hand Cigar Making Supervisor position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

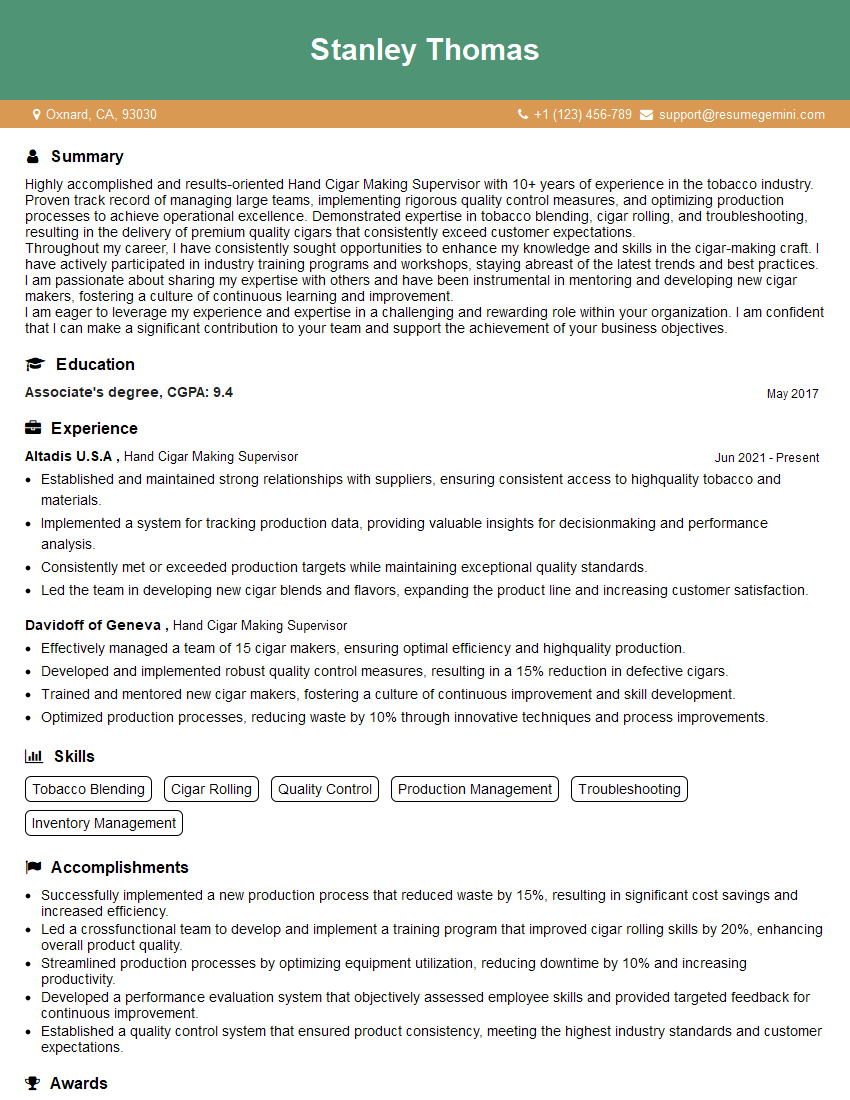

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hand Cigar Making Supervisor

1. Explain the key factors that influence the quality of hand-rolled cigars.

- Tobacco quality: The type of tobacco leaf used plays a crucial role in the flavor and aroma of the cigar.

- Blend composition: The combination of different tobacco types and their proportions affects the cigar’s strength, taste, and burn characteristics.

- Roller’s skill: The experience and technique of the cigar roller impact the cigar’s shape, firmness, and draw resistance.

- Curing and aging: The process of curing and aging the tobacco influences its flavor, aroma, and burn quality.

- Storage conditions: Humidity and temperature levels during storage can affect the cigar’s moisture content and overall quality.

2. What are the different types of tobacco leaves used in cigar making, and how do they contribute to the cigar’s flavor profile?

Broadleaf

- Dark, robust, and full-flavored

- Often used as wrapper leaves

Shade-grown

- Light, mild, and aromatic

- Grown under shade to protect from sunlight

Connecticut

- Sweet, smooth, and nutty

- Versatile and can be used for various cigar types

Maduro

- Dark, rich, and spicy

- Often used for aging and full-bodied cigars

3. Describe the steps involved in hand-rolling a cigar, including the techniques used to achieve the desired shape and firmness.

- Preparing the leaves: Removing the stem and veins from the tobacco leaves.

- Blending: Mixing different types of tobacco leaves to create the desired flavor profile.

- Bunching: Forming the core of the cigar by rolling the blended leaves.

- Rolling: Covering the bunch with wrapper leaves while applying pressure to achieve the desired shape and firmness.

- Capping: Applying a final piece of tobacco to the head of the cigar.

- Finishing: Shaping and smoothing the cigar using a mold or press.

4. What are the key quality control measures implemented during the hand-rolling process to ensure consistent production?

- Visual inspection: Checking the appearance, shape, and consistency of the cigars.

- Draw resistance testing: Ensuring the cigar draws smoothly and consistently.

- Moisture content measurement: Maintaining the optimal moisture level for burn quality and flavor.

- Sensory evaluation: Tasting and assessing the cigars for flavor, aroma, and overall quality.

- Aging and storage monitoring: Ensuring proper conditions during curing, aging, and storage.

5. How do you manage the team of cigar rollers to maintain productivity and quality standards?

- Training and development: Providing training to ensure rollers master the hand-rolling techniques.

- Performance monitoring: Tracking individual and team performance to identify areas for improvement.

- Feedback and communication: Providing regular feedback and fostering open communication to address issues.

- Collaboration and problem-solving: Encouraging teamwork to solve problems and improve efficiency.

- Motivation and recognition: Recognizing and rewarding high performance to maintain motivation.

6. What are the safety precautions and industry regulations that must be followed during the hand-rolling process?

- Tobacco handling: Proper handling of tobacco to minimize exposure to nicotine.

- Ventilation: Ensuring adequate ventilation to remove tobacco dust and prevent respiratory issues.

- Ergonomics: Providing comfortable workstations to prevent repetitive stress injuries.

- Hygiene: Maintaining a clean and sanitary work environment to prevent contamination.

- Compliance: Adhering to all applicable industry regulations and standards.

7. How do you stay up-to-date with the latest advancements and trends in hand cigar making?

- Industry events: Attending conferences and exhibitions to interact with experts and learn about new techniques.

- Trade publications: Reading industry magazines and journals to stay informed about trends.

- Online resources: Researching online forums, websites, and videos to access the latest information.

- Networking: Connecting with other professionals in the field to exchange knowledge and ideas.

- Continuing education: Enrolling in workshops or training programs to enhance skills.

8. Describe a challenging situation you faced in your previous role as a Hand Cigar Making Supervisor and how you resolved it.

In my previous role, I encountered a situation where several newly hired rollers were struggling to meet production targets while maintaining quality standards. To address this, I implemented a comprehensive training program that focused on enhancing their rolling techniques and understanding of tobacco blending. Additionally, I assigned more experienced rollers as mentors to provide guidance and support. Through this approach, I successfully improved the rollers’ skills, resulting in increased productivity and consistent quality.

9. What are your goals for this role as a Hand Cigar Making Supervisor in our company?

- Enhance the overall quality of hand-rolled cigars produced by our team.

- Increase productivity while maintaining the highest standards of craftsmanship.

- Develop and implement innovative techniques to improve efficiency and consistency.

- Foster a positive and collaborative work environment for our team of cigar rollers.

- Contribute to the company’s success by delivering exceptional hand-rolled cigars to our customers.

10. Why are you the most suitable candidate for this position?

- My extensive experience and proven track record as a Hand Cigar Making Supervisor.

- Deep understanding of the hand-rolling process, tobacco blending, and quality control.

- Exceptional leadership and communication skills to effectively manage and motivate a team.

- Passion for the art of hand cigar making and commitment to delivering consistent excellence.

- Eagerness to contribute my expertise and collaborate with your team to achieve the company’s goals.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hand Cigar Making Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hand Cigar Making Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Hand Cigar Making Supervisor is responsible for overseeing the production of hand-rolled cigars, ensuring that they meet the highest standards of quality and craftsmanship.

1. Production Management

Directs and coordinates the activities of cigar makers, ensuring that production quotas are met efficiently and effectively.

- Plans daily production schedule and allocates resources to meet deadlines.

- Monitors progress and identifies bottlenecks, implementing solutions to improve efficiency.

2. Quality Control

Inspects raw materials and finished products, ensuring that they conform to established quality standards.

- Conducts regular quality checks throughout the production process, identifying and correcting defects.

- Provides feedback to cigar makers on areas for improvement based on quality analysis.

3. Training and Development

Implements training programs for new and existing cigar makers, developing their skills and knowledge.

- Evaluates training needs and designs tailored programs to enhance employee capabilities.

- Provides ongoing support and guidance to cigar makers, promoting professional development.

4. Inventory Management

Maintains inventory of raw materials, packaging, and finished products to ensure adequate supplies.

- Coordinates with suppliers to secure timely delivery of materials and minimize stockouts.

- Implements inventory tracking systems to optimize stock levels and prevent waste.

Interview Tips

To ace the interview for the Hand Cigar Making Supervisor position, consider the following tips:

1. Research the Company and Industry

Demonstrate your knowledge of the cigar industry, the company’s history, and their commitment to quality.

- Visit the company’s website and read industry publications to gather information.

- Identify specific examples of the company’s focus on craftsmanship and customer satisfaction.

2. Highlight Your Experience and Skills

Emphasize your experience in cigar making, production management, and quality control.

- Quantify your achievements using specific metrics and results.

- Provide examples of how you have implemented innovative solutions to improve efficiency or enhance quality.

3. Show Your Passion for Cigars

Convey your genuine appreciation and enthusiasm for the art of cigar making.

- Describe your personal experiences with cigars and how they have influenced your passion for the industry.

- Discuss your knowledge of different cigar blends, wrappers, and aging techniques.

4. Be Prepared for Technical Questions

Expect questions about the cigar making process, production techniques, and quality standards.

- Review common cigar making methods and be ready to explain the steps involved.

- Prepare examples of quality control procedures you have implemented to ensure the highest standards.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Hand Cigar Making Supervisor, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Hand Cigar Making Supervisor positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.