Feeling lost in a sea of interview questions? Landed that dream interview for Hand Coremaker but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Hand Coremaker interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

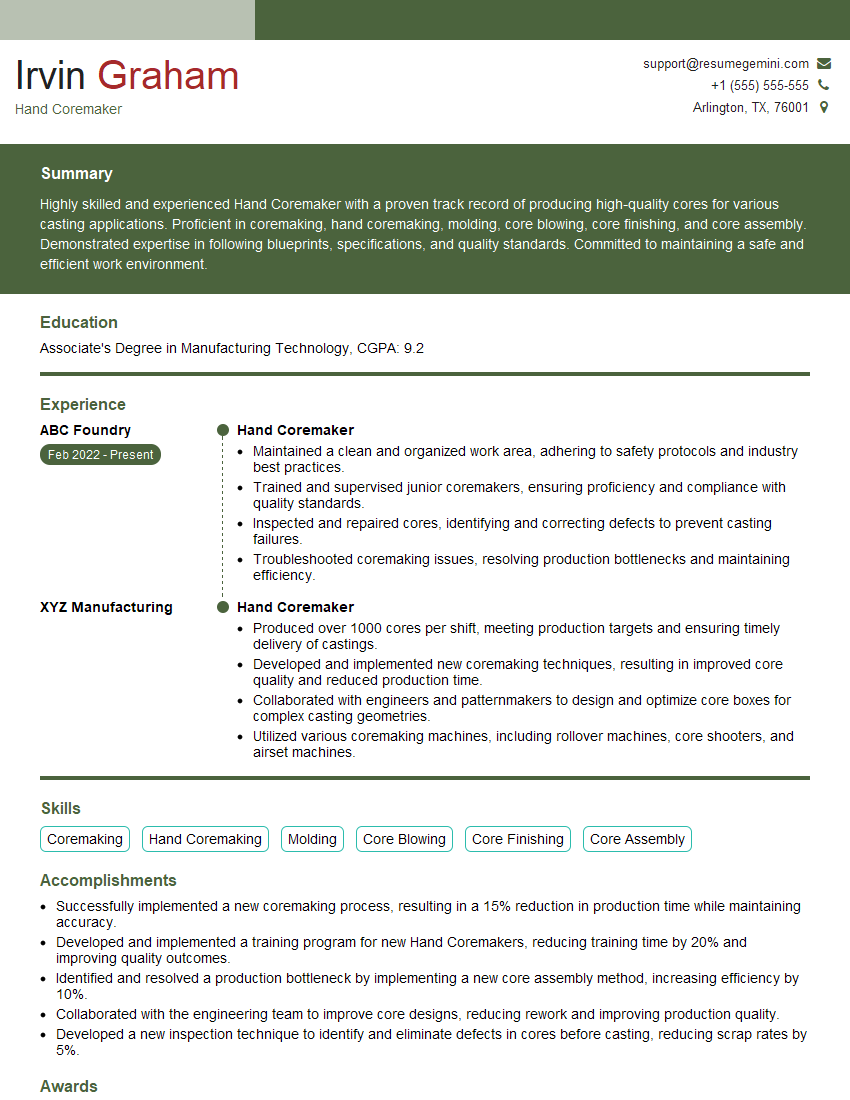

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hand Coremaker

1. What are the key responsibilities of a Hand Coremaker?

- Following the work instruction to make the cores.

- Monitoring the core production and reporting any issues to the supervisor.

- Maintaining the cleanliness of the work area and equipment.

- Working safely and efficiently.

2. What are the different types of coremaking processes?

Sand coremaking

- Green sand coremaking

- Dry sand coremaking

Shell coremaking

- No-bake shell coremaking

- Cold box shell coremaking

- Hot box shell coremaking

Investment casting

- Lost wax casting

- Ceramic shell casting

3. What are the different types of core boxes?

- Split core boxes

- Collapsible core boxes

- Lift-off core boxes

- Rollover core boxes

4. What are the different types of core binders?

- Organic binders

- Inorganic binders

- No-bake binders

5. What are the key factors that affect the quality of cores?

- The quality of the sand

- The type of binder

- The coremaking process

- The curing process

6. What are the different types of core defects?

- Cracks

- Scabs

- Veins

- Blowholes

7. What are the different ways to prevent core defects?

- Using high-quality sand

- Using the correct type of binder

- Following the coremaking process correctly

- Properly curing the cores

8. What are the different types of coremaking equipment?

- Core shooters

- Core blowers

- Core ovens

- Core benches

9. What are the safety precautions that should be taken when working with coremaking equipment?

- Wear appropriate personal protective equipment

- Keep the work area clean and free of tripping hazards

- Never operate equipment that is not properly guarded

- Never work on equipment that is energized

10. What are the troubleshooting tips for common coremaking problems?

- Cracks: Reduce the amount of binder, increase the moisture content of the sand, or use a different type of binder.

- Scabs: Increase the amount of binder, decrease the moisture content of the sand, or use a different type of binder.

- Veins: Increase the amount of binder, decrease the moisture content of the sand, or use a different type of binder.

- Blowholes: Reduce the amount of binder, increase the moisture content of the sand, or use a different type of binder.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hand Coremaker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hand Coremaker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Hand Coremaker is responsible for creating molds and cores that are used in the casting process. They work with a variety of materials, including metal, plastic, and ceramic, and use a variety of tools and techniques to create their products. Key job responsibilities include:

1. Designing and creating molds and cores

Hand Coremakers work with engineers and other designers to create molds and cores that meet specific specifications. They use a variety of materials, including metal, plastic, and ceramic, and use a variety of tools and techniques to create their products.

- Reading and interpreting blueprints and other technical drawings

- Selecting the appropriate materials for the mold or core

- Using a variety of tools and techniques to create the mold or core

- Inspecting the mold or core to ensure that it meets specifications

2. Operating and maintaining equipment

Hand Coremakers operate and maintain a variety of equipment, including molding machines, core shooters, and ovens. They also use a variety of hand tools, such as hammers, chisels, and files.

- Setting up and operating molding machines

- Maintaining and repairing molding machines

- Using a variety of hand tools

- Troubleshooting problems with equipment

3. Working with other team members

Hand Coremakers work with a variety of other team members, including engineers, designers, and other production workers. They must be able to communicate effectively with others and work as part of a team.

- Working with engineers and designers to create molds and cores

- Working with other production workers to produce castings

- Communicating effectively with others

- Working as part of a team

Interview Tips

To ace your interview for a Hand Coremaker position, you should:

1. Research the company and the position

Before your interview, take some time to research the company and the Hand Coremaker position. This will help you to understand the company’s culture and values, as well as the specific requirements of the job. You can find information about the company on their website, social media pages, and other online resources.

- Visit the company’s website

- Read the job description carefully

- Research the company’s industry and competitors

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and clearly.

- Use the STAR method to answer interview questions

- Prepare for behavioral interview questions

- Practice your answers with a friend or family member

3. Dress professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing a suit or business casual attire. You should also make sure that your clothes are clean and pressed.

- Wear a suit or business casual attire

- Make sure your clothes are clean and pressed

- Pay attention to your personal hygiene

4. Be yourself

It is important to be yourself during your interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Just relax, be confident, and let your personality shine through.

- Be yourself

- Relax and be confident

- Let your personality shine through

Next Step:

Now that you’re armed with the knowledge of Hand Coremaker interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Hand Coremaker positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini