Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Hand Former position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

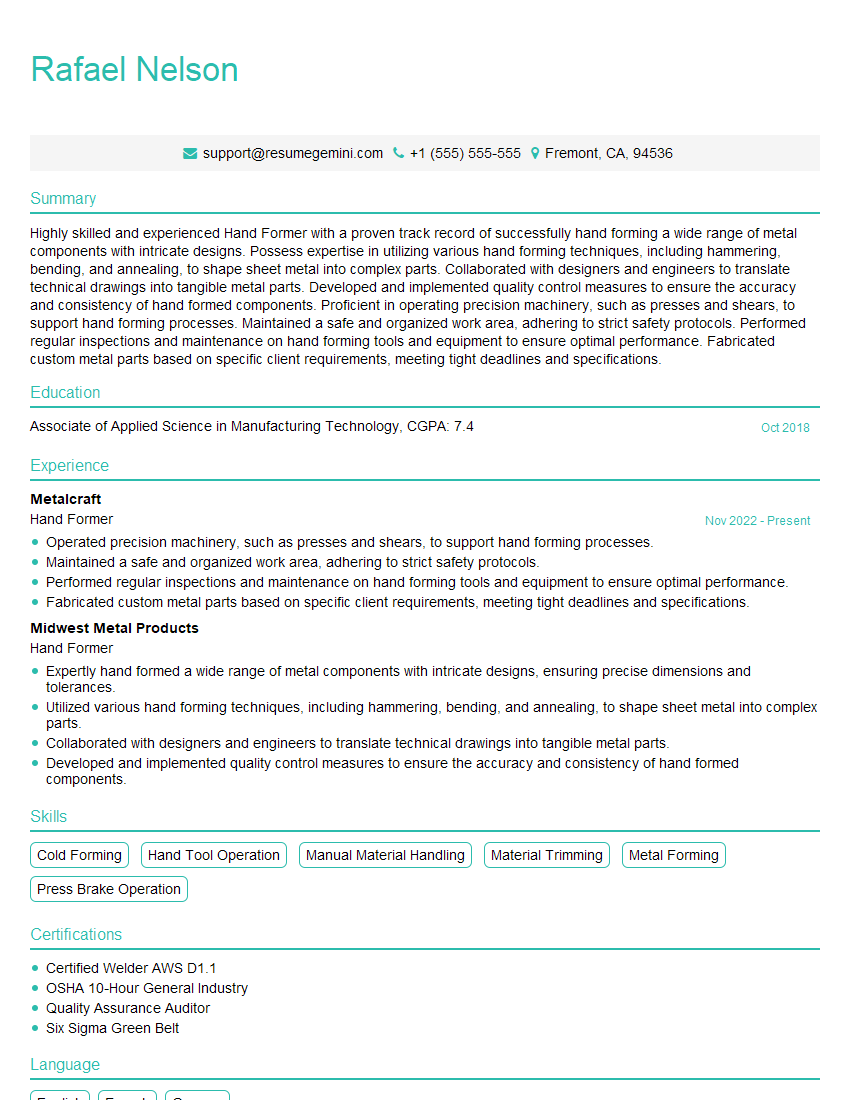

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hand Former

1. What is your experience in hand forming various metal components?

I have over 5 years of experience in hand forming metal components, including a variety of shapes and sizes. I have worked with a variety of metals, including steel, aluminum, copper, and brass. I am proficient in using a variety of hand tools, including hammers, pliers, files, and shears. I am also experienced in using power tools, such as drills, grinders, and lathes.

2. How do you ensure that the final product meets the required specifications?

Dimension Accuracy

- Use precision measuring tools to ensure accurate dimensions.

- Check measurements at regular intervals during the forming process.

Shape and Form

- Follow detailed technical drawings or specifications.

- Use jigs or templates to maintain consistent shapes and angles.

Surface Finish

- Use appropriate tools and techniques to achieve the desired surface finish.

- Smooth or polish surfaces as required.

Material Quality

- Inspect the material for defects or damage before forming.

- Use proper forming techniques to prevent damage or weakening of the material.

3. What are the different techniques used in hand forming metal components?

The different techniques used in hand forming metal components include:

- Bending: Using a hammer or press to create angles or curves in the metal.

- Stretching: Pulling or stretching the metal to increase its length or width.

- Shrinking: Compressing or shrinking the metal to reduce its size.

- Flanging: Creating a raised edge or flange on the metal.

- Rolling: Using a roller to shape or flatten the metal.

4. What are the safety precautions that you take when hand forming metal components?

The safety precautions that I take when hand forming metal components include:

- Wearing appropriate personal protective equipment (PPE), such as gloves, safety glasses, and earplugs.

- Ensuring that the work area is well-ventilated and free of tripping hazards.

- Using sharp tools that are in good condition.

- Being aware of the potential for hot or sharp metal and taking appropriate precautions.

- Following established safety protocols and procedures.

5. What are some of the challenges you have faced in hand forming metal components?

Some of the challenges that I have faced in hand forming metal components include:

- Working with complex shapes or designs.

- Achieving precise dimensions and tolerances.

- Preventing distortion or damage to the metal during forming.

- Working with different types of metals, each with its own unique properties.

- Meeting tight deadlines while maintaining quality standards.

6. What are the advantages of hand forming metal components over other manufacturing methods?

The advantages of hand forming metal components over other manufacturing methods include:

- Flexibility: Hand forming allows for greater flexibility in design and customization.

- Cost-effectiveness: Hand forming can be more cost-effective for small-batch or prototype production.

- Precision: Skilled hand formers can achieve high levels of precision and accuracy.

- Versatility: Hand forming can be used to create a wide range of shapes and sizes.

- Craftsmanship: Hand forming allows for the creation of unique and artistic pieces.

7. What are some of the applications where hand formed metal components are commonly used?

Hand formed metal components are commonly used in a variety of applications, including:

- Automotive parts

- Aerospace components

- Medical devices

- Architectural elements

- Jewelry and decorative items

8. What are the key qualities of a successful hand former?

The key qualities of a successful hand former include:

- Strong technical skills and knowledge of metalworking techniques.

- Precision and attention to detail.

- Creativity and problem-solving abilities.

- Physical strength and endurance.

- Excellent communication and teamwork skills.

9. What is your approach to continuous improvement in your role as a hand former?

My approach to continuous improvement in my role as a hand former includes:

- Regularly seeking feedback from supervisors, colleagues, and customers.

- Identifying areas for improvement in my skills, knowledge, and processes.

- Participating in training and development opportunities.

- Experimenting with new techniques and technologies.

- Sharing my knowledge and expertise with others.

10. What are your career goals and aspirations as a hand former?

My career goals and aspirations as a hand former include:

- Becoming a highly skilled and experienced hand former.

- Working on challenging and complex projects.

- Contributing to the success of the company I work for.

- Mentoring and training future hand formers.

- Exploring new technologies and applications for hand forming.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hand Former.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hand Former‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Hand Formers are responsible for shaping metal materials using specialized hand tools and machinery to create a variety of products.

1. Form and shape metal materials

Using hand tools and machinery, hand formers shape and form metal materials into desired shapes and sizes.

- Use hammers, pliers, and other hand tools to shape metal.

- Operate machines such as presses and brakes to bend and form metal.

2. Inspect and measure formed parts

Hand formers inspect and measure formed parts to ensure they meet specifications.

- Use measuring tools such as calipers and micrometers to measure parts.

- Inspect parts for defects and imperfections.

3. Maintain tools and equipment

Hand formers maintain tools and equipment to ensure they are in good working condition.

- Clean and lubricate tools and equipment.

- Perform minor repairs on tools and equipment.

4. Follow safety procedures

Hand formers follow safety procedures to prevent accidents and injuries.

- Wear appropriate safety gear such as gloves, safety glasses, and earplugs.

- Follow lockout/tagout procedures when working on machinery.

Interview Tips

To ace the interview for a Hand Former position, it is crucial to:

1. Research the company and the position

Learn about the company’s history, values, and products. Understanding the company’s culture and the specific requirements of the Hand Former role will help you tailor your answers to the interviewer’s questions.

- Visit the company’s website and social media pages.

- Read industry publications and news articles.

2. Practice your answers to common interview questions

Prepare for questions about your experience, skills, and qualifications. Practice answering questions clearly and concisely, highlighting your relevant experience and abilities.

- Write down your answers to common interview questions.

- Practice your answers with a friend or family member.

3. Dress professionally and arrive on time

First impressions matter. Dress professionally and arrive on time for your interview. This shows the interviewer that you are respectful of their time and that you take the interview seriously.

- Wear a clean, pressed suit or business casual attire.

- Arrive on time for your interview.

4. Be enthusiastic and positive

Employers are looking for candidates who are enthusiastic about the position and who have a positive attitude. Show the interviewer that you are excited about the opportunity to work for their company.

- Smile and make eye contact with the interviewer.

- Be positive and enthusiastic about your qualifications.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Hand Former interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.