Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Hand Gluer and Slicer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Hand Gluer and Slicer so you can tailor your answers to impress potential employers.

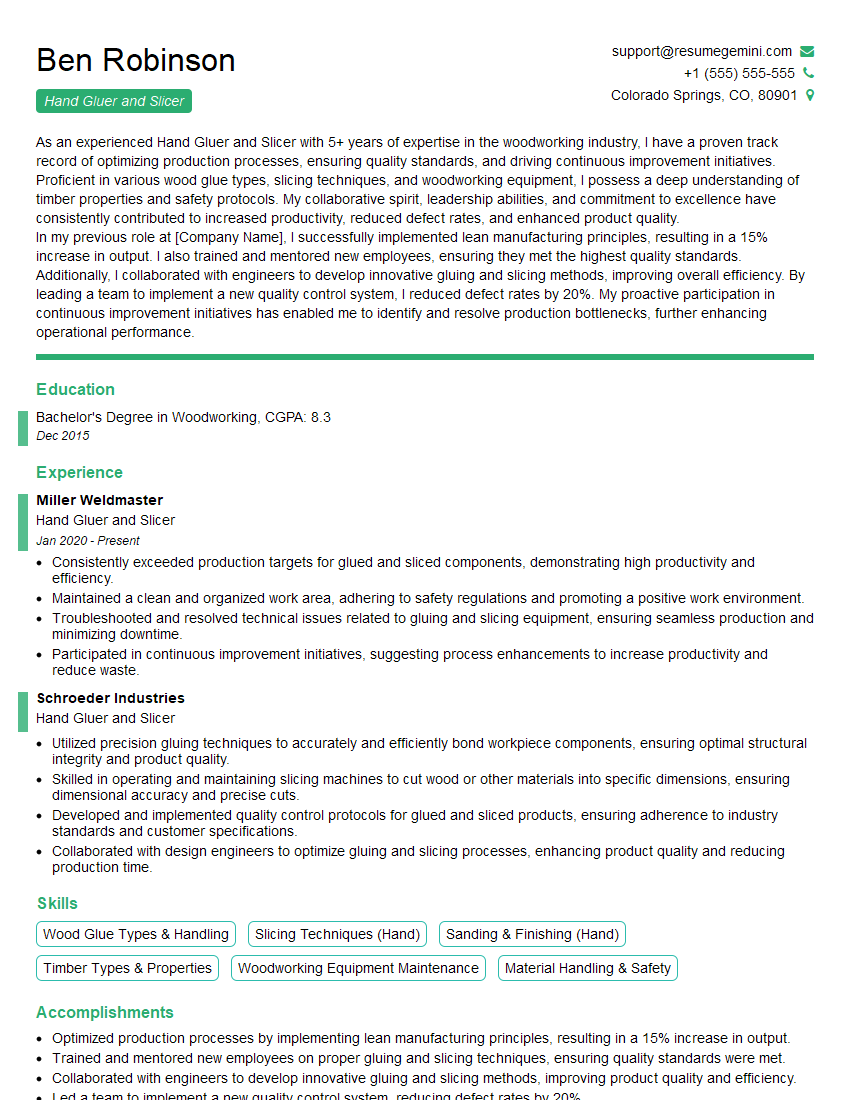

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hand Gluer and Slicer

1. What are the different types of glues used in hand gluing and slicing?

There are many different types of glues that can be used in hand gluing and slicing, including:

- Polyvinyl acetate (PVA) glue

- Cyanoacrylate (CA) glue

- Epoxy glue

- Hide glue

- Hot melt glue

2. What are the factors to consider when selecting a glue for a particular application?

Strength

- The strength of the glue is a key factor to consider, as it will determine how well the glue will hold the materials together.

Flexibility

- The flexibility of the glue is also important, as it will determine how well the glue will withstand movement without breaking.

Drying time

- The drying time of the glue is also a factor to consider, as it will determine how long it will take for the glue to set.

Cost

- The cost of the glue is also a factor to consider, as it will determine how much it will cost to use the glue.

3. What are the different types of hand gluing and slicing machines?

There are many different types of hand gluing and slicing machines, including:

- Manual hand gluing machines

- Semi-automatic hand gluing machines

- Automatic hand gluing machines

- Manual hand slicing machines

- Semi-automatic hand slicing machines

- Automatic hand slicing machines

4. What are the safety precautions that must be taken when using hand gluing and slicing machines?

There are many different safety precautions that must be taken when using hand gluing and slicing machines, including:

- Always wear appropriate safety gear, such as gloves, safety glasses, and a dust mask.

- Never operate a hand gluing or slicing machine while under the influence of drugs or alcohol.

- Always keep your hands away from the blade when operating a hand slicing machine.

- Never use a hand gluing or slicing machine that is not properly maintained.

5. What are the different types of materials that can be glued and sliced using hand gluing and slicing machines?

There are many different types of materials that can be glued and sliced using hand gluing and slicing machines, including:

- Wood

- Metal

- Plastic

- Glass

- Ceramic

6. What are the different types of finishes that can be applied to glued and sliced materials?

There are many different types of finishes that can be applied to glued and sliced materials, including:

- Paint

- Stain

- Varnish

- Shellac

- Wax

7. What are the different types of defects that can occur when gluing and slicing materials?

There are many different types of defects that can occur when gluing and slicing materials, including:

- Glue joints that are not strong enough

- Glue joints that are not flexible enough

- Glue joints that are not waterproof

- Glue joints that are not heat resistant

- Sliced materials that are not smooth

- Sliced materials that are not accurate

- Sliced materials that are not consistent

8. What are the different types of maintenance that must be performed on hand gluing and slicing machines?

There are many different types of maintenance that must be performed on hand gluing and slicing machines, including:

- Cleaning the machines

- Lubricating the machines

- Sharpening the blades

- Adjusting the machines

9. What are the different types of troubleshooting that must be performed on hand gluing and slicing machines?

There are many different types of troubleshooting that must be performed on hand gluing and slicing machines, including:

- Troubleshooting glue problems

- Troubleshooting slicing problems

- Troubleshooting machine problems

10. What are the different types of training that must be provided to operators of hand gluing and slicing machines?

There are many different types of training that must be provided to operators of hand gluing and slicing machines, including:

- Training on the safe operation of the machines

- Training on the proper use of the machines

- Training on the maintenance of the machines

- Training on the troubleshooting of the machines

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hand Gluer and Slicer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hand Gluer and Slicer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Hand Gluers and Slicers are responsible for manually gluing and slicing materials such as wood, plastic, or metal in order to create products or components. They may also operate machinery to sand or finish the products. Key job responsibilities include:

1. Gluing

Applying glue to materials using a brush, roller, or other applicator

- Ensuring that the glue is applied evenly and in the correct amount

- Allowing the glue to dry according to the manufacturer’s instructions

2. Slicing

Using a hand saw, band saw, or other cutting tool to slice materials into desired shapes and sizes.

- Following specifications and templates to ensure accuracy

- Ensuring that the cuts are made cleanly and without defects

3. Sanding and Finishing

Using sandpaper or other abrasive materials to smooth and finish the surfaces of products

- Removing burrs, splinters, and other imperfections

- Applying finishes such as paint, varnish, or stain to protect and enhance the appearance of the products

4. Quality Control

Inspecting products for defects and ensuring that they meet quality standards

- Identifying and correcting any errors or mistakes

- Maintaining a clean and organized work area

Interview Tips

Preparing thoroughly for a job interview is key to making a good impression and increasing your chances of getting the job. Here are some tips to help you ace your interview for a Hand Gluer and Slicer position:

1. Research the company and the position

Take the time to learn about the company’s history, culture, and products. This will show that you’re interested in the company and that you’ve taken the time to prepare for the interview. You should also research the specific position you’re applying for, so that you can be prepared to answer questions about the job duties and responsibilities.

2. Practice your answers to common interview questions

There are a number of common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” Prepare your answers to these questions in advance, so that you can deliver them confidently and concisely. You can also practice answering questions about your experience and skills, and how they relate to the job you’re applying for.

3. Dress professionally and arrive on time

First impressions matter, so it’s important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the office environment. You should also arrive on time for your interview, as punctuality shows that you’re respectful of the interviewer’s time.

4. Be prepared to talk about your experience and skills

The interviewer will want to know about your experience and skills, so be prepared to talk about your qualifications. Highlight your relevant experience, and be sure to mention any specific skills or training that you have that would be valuable in the role of Hand Gluer and Slicer. You can also prepare examples of your work to show the interviewer.

5. Ask questions

Asking questions at the end of the interview shows that you’re interested in the position and that you’re engaged in the conversation. It also gives you an opportunity to learn more about the company and the position. Prepare a few questions to ask the interviewer, such as “What are the biggest challenges facing the company right now?” or “What are the opportunities for advancement within the company?”

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Hand Gluer and Slicer interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.