Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Hand or Machine Paster position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

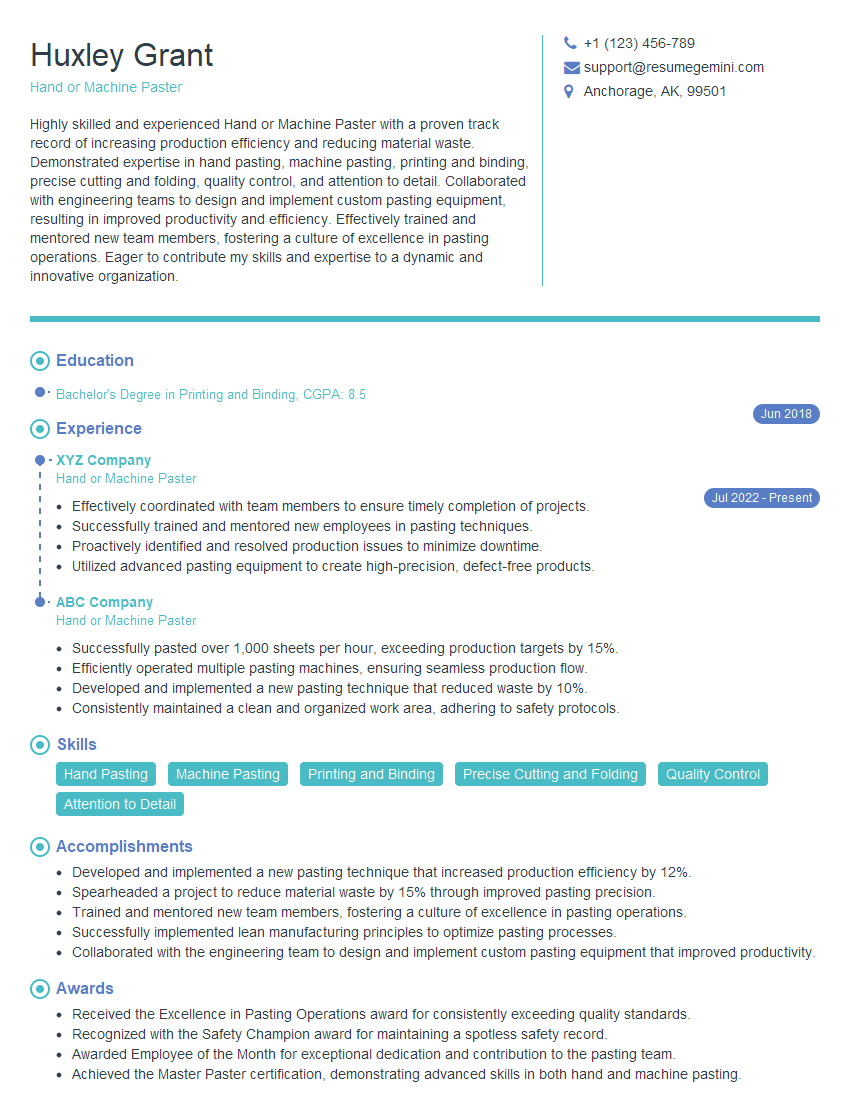

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hand or Machine Paster

1. What are the different types of pastes used in hand and machine pasting?

In hand and machine pasting, various pastes are utilized to adhere materials together. Some common types include:

- Starch paste: Derived from plants, starch paste is a natural adhesive that offers a strong bond. It is often used in bookbinding and wallpapering.

- Dextrin paste: Also plant-based, dextrin paste provides a flexible and durable bond, making it suitable for use in packaging and labeling.

- Hot melt adhesive: This type of paste is applied while hot and forms a strong, quick-setting bond upon cooling. It is commonly used in manufacturing and packaging.

- Pressure-sensitive adhesive: Designed to bond upon application of pressure, pressure-sensitive adhesive is used in tapes, labels, and other applications where a quick and easy bond is desired.

2. What are the key factors to consider when selecting a paste for a specific application?

Factors to consider when selecting an adhesive:

- Material compatibility: The paste should be compatible with the materials being adhered to avoid damage or poor bonding.

- Bond strength: The paste should provide sufficient bond strength to meet the application’s requirements.

- Drying time: The drying time of the paste should align with the specific application and production timeline.

- Cost and availability: The cost and availability of the paste should be taken into account.

Additional considerations for machine pasting:

- Machine compatibility: The paste should be compatible with the machine’s equipment and application system.

- Consistency: The paste should have the appropriate consistency for the machine’s operation, ensuring smooth application.

- Cleanliness: The paste should minimize nozzle clogging and other issues that could affect machine performance.

3. Describe the process of hand pasting a label onto a bottle.

Hand pasting a label onto a bottle involves the following steps:

- Prepare the surface: Clean and dry the bottle’s surface to ensure proper adhesion.

- Apply paste: Dip a brush or roller into the paste and apply a thin, even layer to the back of the label.

- Align and apply: Place the label onto the bottle, aligning it precisely. Press down gently to adhere the label.

- Smooth and press: Use a clean cloth or squeegee to smooth out any air bubbles and press the label firmly against the bottle.

- Inspect: Check the label’s alignment and adhesion to ensure a professional finish.

4. Explain the operation and maintenance of a machine paster.

Operation:

- Loading the machine: Place the materials (e.g., labels, cartons) into the designated feeders or trays.

- Paste application: The machine automatically applies paste to the designated areas of the materials.

- Adhesion: The materials are pressed together to form a bond.

- Drying: The materials pass through a drying zone where the paste sets and the bond strengthens.

Maintenance:

- Regular cleaning: Clean the paste application areas, nozzles, and conveyor belts to prevent clogging and ensure proper operation.

- Paste consistency monitoring: Regularly check the paste consistency and adjust as needed to maintain optimal performance.

- Equipment inspection: Inspect the machine’s components, such as belts, rollers, and sensors, for wear or damage and replace as necessary.

- Calibration: Calibrate the machine regularly to ensure accurate paste application and labeling.

5. Describe the troubleshooting process for a machine paster that is not applying paste evenly.

- Check paste consistency: Ensure the paste has the correct consistency and is free of lumps or contaminants.

- Inspect nozzles: Check the paste nozzles for clogging or damage. Clean or replace as needed.

- Adjust paste flow: Adjust the paste flow rate to achieve an even application.

- Verify pressure settings: Ensure the pressure settings for the paste application are correct.

- Check alignment: Make sure the materials are aligned properly for even paste distribution.

6. Explain how to calculate the amount of paste required for a specific production run.

To calculate the amount of paste required:

- Estimate paste coverage: Determine the approximate coverage area of the paste per unit (e.g., per label or carton).

- Multiply by production quantity: Multiply the estimated coverage area by the total number of units to be pasted.

- Adjust for loss: Account for any potential loss during application (e.g., spillage or evaporation) by adding a buffer percentage.

- Convert to volume: Convert the calculated weight or volume to the unit of the paste (e.g., gallons or liters) for purchasing planning.

7. Discuss the safety precautions that should be taken when working with pastes.

- Read safety data sheets: Familiarize yourself with the specific safety requirements for the paste being used.

- Wear appropriate PPE: Wear protective equipment such as gloves, aprons, and safety glasses to prevent skin and eye contact.

- Maintain good ventilation: Ensure proper ventilation in the work area to minimize exposure to fumes or vapors.

- Avoid prolonged contact: Minimize direct skin contact with the paste and wash hands thoroughly after handling.

- Store and dispose of paste properly: Follow the manufacturer’s instructions for storage and disposal of the paste.

8. Explain the role of quality control in hand and machine pasting operations.

- Label alignment: Ensuring labels are applied accurately and without misalignment.

- Bond strength: Verifying that the pasted materials adhere securely over time.

- Uniformity: Maintaining consistent paste application and labeling results throughout the production run.

- Packaging integrity: Inspecting pasted packages for leaks, tears, or other defects that compromise their integrity.

9. Describe the different methods used to measure paste viscosity.

- Brookfield viscometer: A device that measures the resistance of a fluid to flow, providing a quantitative measure of viscosity.

- Falling ball viscometer: A method that measures the time it takes for a ball to fall through a sample of paste.

- Cone and plate viscometer: A device that measures the torque required to rotate a cone immersed in a sample of paste.

- Capillary viscometer: A method that measures the time it takes for a liquid to flow through a capillary tube.

10. Explain how you would train new employees on hand or machine pasting techniques.

- Classroom instruction: Provide an overview of the pasting process, equipment, and safety procedures.

- Hands-on practice: Guide new employees through the steps of hand or machine pasting, ensuring proper technique.

- Observation and feedback: Observe their work and provide constructive feedback to improve their skills.

- Written materials: Provide written instructions and reference materials for future reference.

- Assessment: Evaluate their progress and ensure they meet the required standards before independent work.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hand or Machine Paster.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hand or Machine Paster‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Hand or Machine Pasters are responsible for adhering various materials together using adhesives, pastes, and tapes. Their primary duties involve using their skilled hands or operating automated machines to assemble products, components, and packaging materials in manufacturing and production settings.

1. Manual Pasting

Hand Pasters manually apply adhesives, glues, or tapes to surfaces using brushes, sponges, or other tools. They align and join materials accurately to ensure proper bonding and structural integrity.

- Applying adhesives to surfaces, often using brushes or sponges

- Aligning and joining materials to create a secure bond

- Using tapes and other bonding materials to assemble components

2. Machine Pasting

Machine Pasters operate automated machines that dispense and apply adhesives or tapes to materials. They monitor the machines, adjust settings, and ensure proper operation to optimize productivity.

- Setting up and operating automated pasting machines

- Feeding materials into the machines and monitoring the dispensing process

- Inspecting and repairing pasted products as needed

3. Quality Control

Both Hand and Machine Pasters are responsible for maintaining quality standards. They inspect pasted products or components to ensure proper bonding and presentation. They may also identify and resolve defects during the pasting process.

- Inspecting pasted products or components for defects

- Identifying and repairing defects during the pasting process

- Ensuring that the finished products meet quality standards

4. Safety and Maintenance

Hand or Machine Pasters follow safety protocols and conduct regular maintenance on equipment to prevent accidents and ensure smooth operations. They may also clean and organize work areas to maintain a safe and efficient work environment.

- Following safety protocols and procedures

- Conducting regular maintenance on equipment

- Cleaning and organizing work areas to ensure safety and efficiency

Interview Tips

Preparing effectively for an interview as a Hand or Machine Paster can increase your chances of success. Here are some essential interview preparation tips:

1. Research the Company and Position

Thoroughly research the company you’re applying to and the specific Hand or Machine Paster position. Learn about their products, services, company culture, and industry reputation. Understanding the company’s mission and values will help you tailor your answers and demonstrate your alignment with their goals.

- Visit the company website and social media pages

- Read industry news and articles about the company

- Look for any company reviews or testimonials online

2. Highlight Relevant Skills and Experience

Review the job description carefully and identify the key skills and experience required for the position. Prepare specific examples from your past work experience that demonstrate your proficiency in these areas. Quantify your accomplishments whenever possible using specific metrics or data points.

- Practice describing your skills and experience using the STAR method (Situation, Task, Action, Result)

- Highlight any experience in manual or automated pasting operations, adhesive application, or quality control

3. Demonstrate Your Attention to Detail and Quality

Hand or Machine Pasters are responsible for ensuring the quality of their work. In your interview, emphasize your attention to detail and commitment to producing high-quality products. Provide examples of how you have consistently met or exceeded quality standards in previous roles.

- Describe your understanding of quality control processes and standards

- Share examples of how you have identified and resolved defects in your work

4. Prepare Questions to Ask

Asking thoughtful questions at the end of the interview demonstrates your interest in the position and the company. Prepare a few questions that will help you gain more insight into the role, the company culture, and the industry. This shows that you are engaged and genuinely interested in the opportunity.

- Ask about the company’s growth plans and industry outlook

- Inquire about opportunities for training and professional development

- Ask for clarification on any aspekts of the job responsibilities or company culture that you are curious about

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Hand or Machine Paster interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!