Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Hand Silvering Supervisor position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

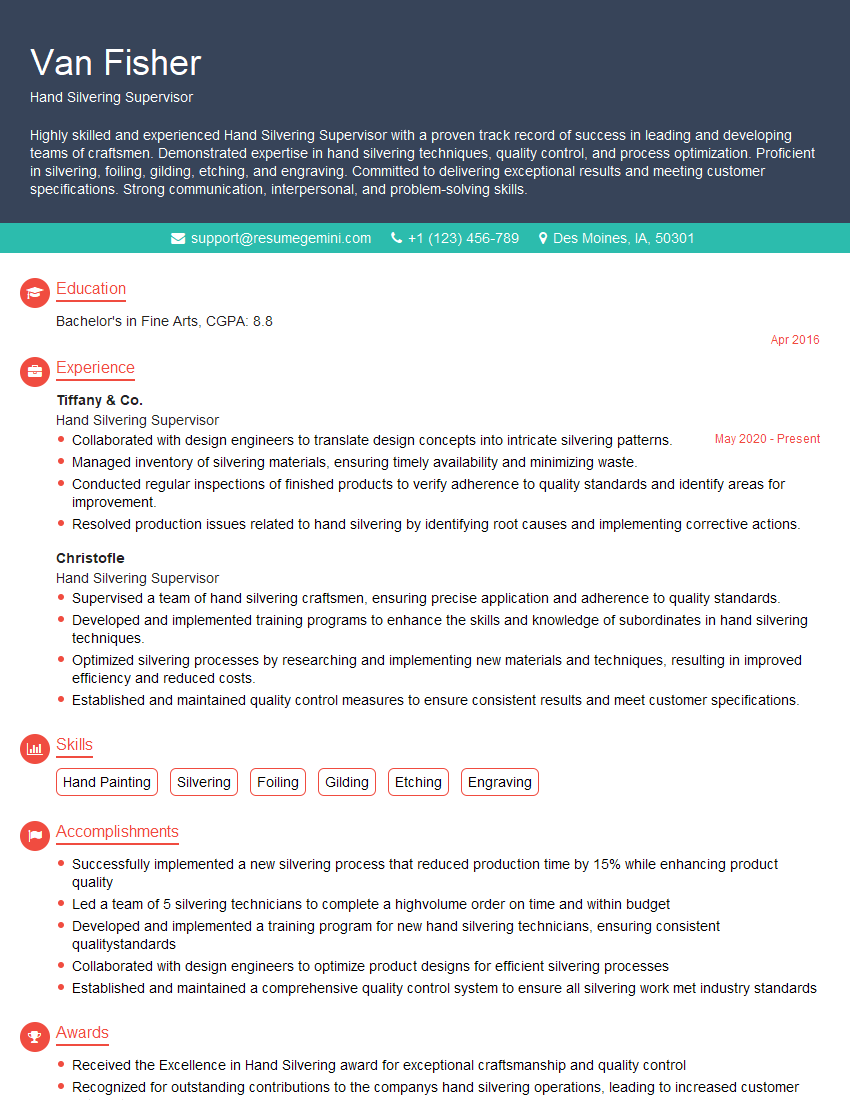

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hand Silvering Supervisor

1. What are the different types of silvering techniques used in hand silvering?

In hand silvering, various techniques are employed to achieve the desired finish. These techniques include:

- Water Gilding: Involves applying gold leaf to a surface primed with water and rabbit skin glue.

- Oil Gilding: Utilizes a preparation of linseed oil and japanner’s gold size to adhere gold leaf to a surface.

- Silvering: Similar to water gilding, but uses silver leaf instead of gold leaf.

- Tarnish Silvering: Creates an aged or antique look by chemically tarnishing silver leaf.

- Patination: Applies chemicals or heat to create various colors and textures on silver surfaces.

2. How do you prepare a surface for hand silvering?

Surface preparation is crucial for successful hand silvering. The process typically involves:

Cleaning:

- Removing dirt, grease, and other contaminants from the surface.

- Using solvents or detergents to ensure a clean base for adhesion.

Priming:

- Applying a base layer to improve adhesion between the silver leaf and the surface.

- The type of primer used depends on the silvering technique and the material of the surface.

Sizing:

- Applying an adhesive to the primed surface before applying silver leaf.

- The type of size used depends on the silvering technique.

3. What are the key factors to consider when selecting the correct size for hand silvering?

Choosing the appropriate size for hand silvering is essential. Factors to consider include:

- Type of Silvering Technique: Different techniques require specific types of size, such as water-based or oil-based size.

- Surface Material: The size should be compatible with the surface being silvered to ensure proper adhesion.

- Drying Time: Consider the drying time of the size to allow sufficient time for application and manipulation of the silver leaf.

- Tack Time: The tack time, or the period when the size is receptive to the silver leaf, is crucial for successful application.

4. Describe the process of applying silver leaf to a surface.

Applying silver leaf involves several steps:

- Cutting Silver Leaf: Silver leaf is cut into smaller pieces using a gilder’s knife.

- Picking Up Silver Leaf: Using a gilder’s tip, the silver leaf is carefully picked up and placed on the sized surface.

- Smoothing and Burnishing: The silver leaf is smoothed using a soft brush or a burnishing tool to remove wrinkles and enhance adhesion.

- Gilding Techniques: Various techniques, such as burnishing, gilding paste, or water gilding, can be used to achieve different effects.

5. How do you protect the silver leaf from tarnishing?

Protecting silver leaf from tarnishing is crucial for preserving its appearance. Methods include:

- Top Coating: Applying a clear protective varnish or lacquer to the silver leaf.

- Waxing: Using natural or synthetic waxes to create a protective barrier.

- Environmental Control: Maintaining proper temperature and humidity levels to minimize tarnishing.

- Archival Framing: Framing the silvered object using acid-free materials to prevent contact with harmful elements.

6. What are the common defects that can occur in hand silvering and how can they be prevented?

Defects in hand silvering can include:

- Blisters: Caused by trapped air or moisture under the silver leaf, leading to raised areas.

- Cracks: Result from improper application, drying conditions, or physical damage.

- Peeling: Occurs when the silver leaf loses adhesion to the surface due to poor preparation or environmental factors.

- Tarnishing: Caused by exposure to sulfur or other tarnishing agents, resulting in discoloration.

Prevention measures include:

- Proper surface preparation and application of size.

- Controlled drying conditions to prevent blisters or cracks.

- Proper handling and storage to avoid damage.

- Protection from environmental factors that cause tarnishing.

7. What is your approach to quality control in hand silvering?

Quality control in hand silvering involves:

- Inspection: Regularly inspecting silvered surfaces for defects, such as blisters, cracks, or peeling.

- Documentation: Keeping records of materials used, techniques applied, and any defects encountered.

- Process Improvement: Identifying areas for improvement in the hand silvering process to enhance quality and efficiency.

- Training and Supervision: Providing training to subordinates and supervising their work to ensure adherence to quality standards.

8. How do you stay up-to-date with the latest techniques and advancements in hand silvering?

To stay current with the latest techniques and advancements in hand silvering, I:

- Attend Industry Events: Participate in conferences, workshops, and exhibitions to learn about new materials, methods, and trends.

- Read Trade Publications: Subscribe to industry magazines and journals to stay informed about best practices and innovative techniques.

- Online Research: Regularly search for online resources, tutorials, and articles to expand my knowledge.

- Network with Experts: Connect with other hand silvering professionals through online forums and social media to exchange ideas and learn from their experiences.

9. How do you manage a team of hand silvering artisans?

Managing a team of hand silvering artisans involves:

- Setting Clear Expectations: Communicating project goals, deadlines, and quality standards to the team.

- Providing Training and Support: Ensuring that team members have the necessary skills and knowledge to perform their tasks effectively.

- Motivating and Inspiring: Creating a positive and supportive work environment to encourage productivity and creativity.

- Monitoring Progress and Providing Feedback: Regularly tracking team progress and providing constructive feedback to enhance performance.

10. How do you handle customer complaints or dissatisfaction related to hand silvering?

When handling customer complaints or dissatisfaction related to hand silvering, I:

- Listen Actively: Allow the customer to fully express their concerns and understand their perspective.

- Investigate the Issue: Thoroughly investigate the complaint to determine the root cause and identify any potential solutions.

- Communicate Clearly: Clearly explain the findings of the investigation and the proposed solutions to the customer.

- Resolve the Complaint: Work with the customer to find a mutually acceptable solution that meets their needs and restores their satisfaction.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hand Silvering Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hand Silvering Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Hand Silvering Supervisor is responsible for overseeing and managing the hand silvering process in a manufacturing environment. Their primary duties include:

1. Production Management

• Establish and maintain production schedules to meet customer demand

• Monitor production lines and optimize processes to improve efficiency and quality

• Identify and resolve production issues and bottlenecks

2. Quality Control

• Inspect hand silvered products to ensure they meet quality standards

• Develop and implement quality control procedures

• Train and supervise hand silvering operators on quality standards

3. Safety and Compliance

• Enforce safety regulations and ensure compliance with industry standards

• Conduct safety training and provide safety equipment

• Maintain a clean and organized work environment

4. Team Management

• Supervise and lead a team of hand silvering operators

• Train, motivate, and evaluate team members

• Foster a positive and productive work environment

Interview Tips

To prepare for the Hand Silvering Supervisor interview, consider the following tips:

1. Research the Company and Role

• Visit the company website to learn about their mission, values, and products

• Review the job description carefully to understand the specific responsibilities and requirements

2. Highlight Relevant Experience and Skills

• Quantify your accomplishments and provide specific examples of your work experience

• Emphasize your knowledge of hand silvering techniques, quality control, and team management

3. Prepare for Technical Questions

• Be prepared to answer questions about hand silvering processes, materials, and equipment

• Review common industry standards and regulations related to hand silvering

4. Practice Common Interview Questions

• Prepare answers to standard interview questions such as “Tell me about yourself” and “Why are you interested in this role?”

• Practice answering questions in a clear, concise, and professional manner

5. Arrive Prepared

• Dress professionally and arrive on time for the interview

• Bring a portfolio or samples of your work if relevant

• Be confident and enthusiastic, and ask thoughtful questions about the role and company

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Hand Silvering Supervisor, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Hand Silvering Supervisor positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.