Are you gearing up for an interview for a Hand Stone Polisher position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Hand Stone Polisher and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

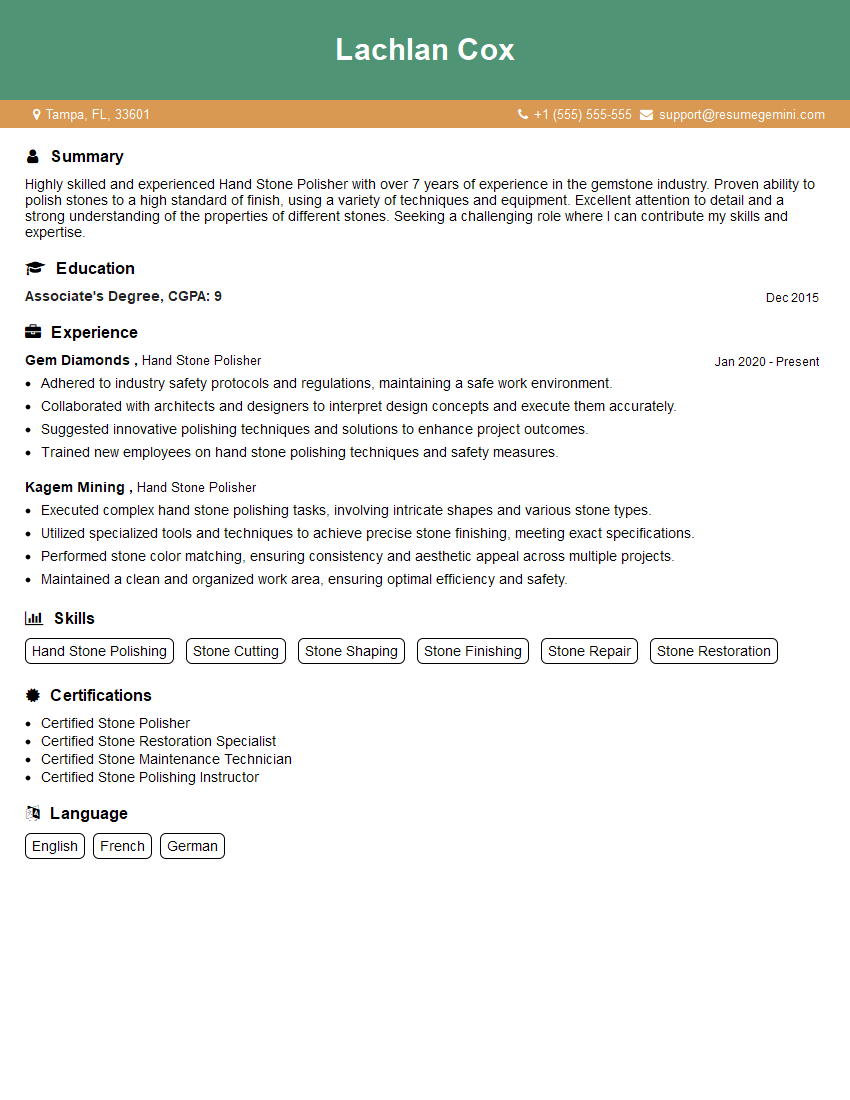

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hand Stone Polisher

1. What techniques do you use to achieve a high-quality polish on stone surfaces?

To achieve a high-quality polish on stone surfaces, I utilize a multi-step process. Firstly, I clean the surface thoroughly to remove any contaminants. Then, I use progressively finer grades of abrasive pads or powders to grind away the surface, leveling it and removing any imperfections. Subsequently, I apply a polishing compound to the surface and use a polishing wheel or buffer to create a smooth, glossy finish. I also pay attention to the speed and pressure applied during the polishing process to ensure optimal results.

2. How do you determine the appropriate grit size of abrasive pads or powders for different stone types?

Determining the Right Grit Size

- Consider the hardness and porosity of the stone.

- Start with coarser grits to remove scratches and level the surface.

- Gradually transition to finer grits to achieve the desired polish.

Common Grit Sizes

- Coarse grits (e.g., 50-100 grit) for removing deep scratches and leveling.

- Medium grits (e.g., 200-400 grit) for smoothing the surface.

- Fine grits (e.g., 800-1200 grit) for creating a high-quality polish.

3. What types of polishing compounds do you use for various stone surfaces?

The type of polishing compound I use depends on the stone surface and the desired finish. For softer stones like marble, I might use a compound with a higher percentage of abrasives to achieve a matte finish. For harder stones like granite, I would select a compound with less abrasive content to create a glossy finish. I also consider the color of the stone and the intended application to choose the most suitable polishing compound.

4. How do you handle situations where the stone surface has deep scratches or chips?

When dealing with deep scratches or chips in a stone surface, I follow a careful approach to avoid further damage. Firstly, I assess the extent of the damage and determine the best course of action. If the scratches or chips are minor, I might use a combination of abrasive pads and polishing compounds to level the surface and restore its smoothness. However, if the damage is more severe, I would consider using specialized repair techniques such as epoxy or stone filler to fill in the imperfections and then polish the surface to match the surrounding area.

5. What safety precautions do you observe when operating hand-held polishing equipment?

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and a dust mask.

- Ensure the work area is well-ventilated to prevent inhalation of dust particles.

- Inspect the equipment before use and ensure it is in good working condition.

- Handle the equipment with care, avoid overexertion, and take breaks to prevent fatigue.

- Follow the manufacturer’s instructions for safe operation and maintenance of the equipment.

6. How do you maintain and clean hand-held polishing equipment?

- Regularly clean the equipment to remove dust and abrasive residue.

- Use a soft cloth or brush to avoid scratching the surfaces.

- Lubricate moving parts as per the manufacturer’s recommendations.

- Store the equipment in a dry and clean environment when not in use.

- Have the equipment inspected and serviced by a qualified technician at regular intervals.

7. What factors influence the speed and efficiency of the stone polishing process?

Factors Affecting Speed

- Hardness of the stone.

- Grit size of abrasive pads or powders.

- Type of polishing compound.

- Speed and pressure applied during polishing.

Factors Affecting Efficiency

- Experience and skill of the polisher.

- Quality of hand-held polishing equipment.

- Proper maintenance and cleaning of equipment.

8. Can you describe the different types of finishes that can be achieved on stone surfaces through polishing?

- Matte finish: A dull, non-reflective surface.

- Satin finish: A smooth, slightly reflective surface with a subtle sheen.

- Glossy finish: A highly reflective surface with a mirror-like appearance.

- Honed finish: A smooth, non-reflective surface with a velvety touch.

- Leathered finish: A textured surface with a matte appearance and a natural, aged look.

9. How do you determine the appropriate polishing technique for a particular stone surface?

- Consider the desired finish and the characteristics of the stone.

- Test different techniques on a small, inconspicuous area first.

- Adjust the speed, pressure, and grit size of abrasive pads or powders based on the stone’s hardness and porosity.

- Consult with experienced professionals or refer to industry guidelines for specific stone types.

10. What are some common challenges faced during stone polishing and how do you overcome them?

Challenges and Solutions

- Deep scratches: Use a combination of coarse abrasive pads and specialized repair techniques.

- Uneven surface: Level the surface using progressively finer grades of abrasive pads or powders.

- Discoloration: Identify the cause of discoloration and use appropriate cleaning agents or polishing compounds.

- Equipment malfunction: Inspect the equipment, ensure it is in good working condition, and contact the manufacturer for maintenance or repairs.

- Time constraints: Plan the polishing process efficiently, use the right tools and techniques, and consider outsourcing if necessary.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hand Stone Polisher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hand Stone Polisher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Hand Stone Polishers are responsible for polishing stones by hand using a variety of tools and techniques. They may also be responsible for cutting, shaping, and repairing stones. Key job responsibilities include:

1. Stone Polishing

Polish stones using a variety of tools and techniques to achieve a desired finish.

- Use hand tools such as chisels, hammers, and sandpaper to shape and smooth stones.

- Use power tools such as grinders and buffers to polish stones to a high shine.

2. Cutting and Shaping

Cut and shape stones using a variety of tools and techniques.

- Use hand tools such as saws and chisels to cut stones into desired shapes.

- Use power tools such as grinders and buffers to shape stones to a desired finish.

3. Repairing Stones

Repair stones that have been damaged or broken.

- Use a variety of tools and techniques to repair cracks, chips, and other damage to stones.

- Match the color and texture of the repair to the original stone.

4. Maintaining Equipment

Maintain the equipment used to polish, cut, and shape stones.

- Clean and lubricate equipment regularly.

- Inspect equipment for damage and wear and tear.

Interview Preparation Tips

To prepare for your interview for a Hand Stone Polisher position, you should:

1. Research the Company and Position

Learn about the company’s history, values, and products. Research the specific position you are applying for and the company’s expectations for the role.

- Visit the company’s website and social media pages.

- Read industry news and articles about the company and the stone polishing industry.

2. Practice Your Answers to Common Interview Questions

Prepare for common interview questions, such as:

- Tell me about your experience in stone polishing.

- What are your strengths and weaknesses as a stone polisher?

- Why are you interested in working for our company?

3. Be Prepared to Discuss Your Skills and Experience

Highlight your skills and experience that are relevant to the position, such as:

- Your experience in using hand and power tools to polish, cut, and shape stones.

- Your knowledge of different types of stones and their properties.

- Your ability to work independently and as part of a team.

4. Be Prepared to Ask Questions

Asking thoughtful questions at the end of the interview shows that you are interested in the position and the company. Some good questions to ask include:

- What are the company’s goals for the stone polishing department?

- What are the opportunities for advancement within the company?

- What is the company’s culture like?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Hand Stone Polisher interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!