Are you gearing up for an interview for a Hand Tool Lapper position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Hand Tool Lapper and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

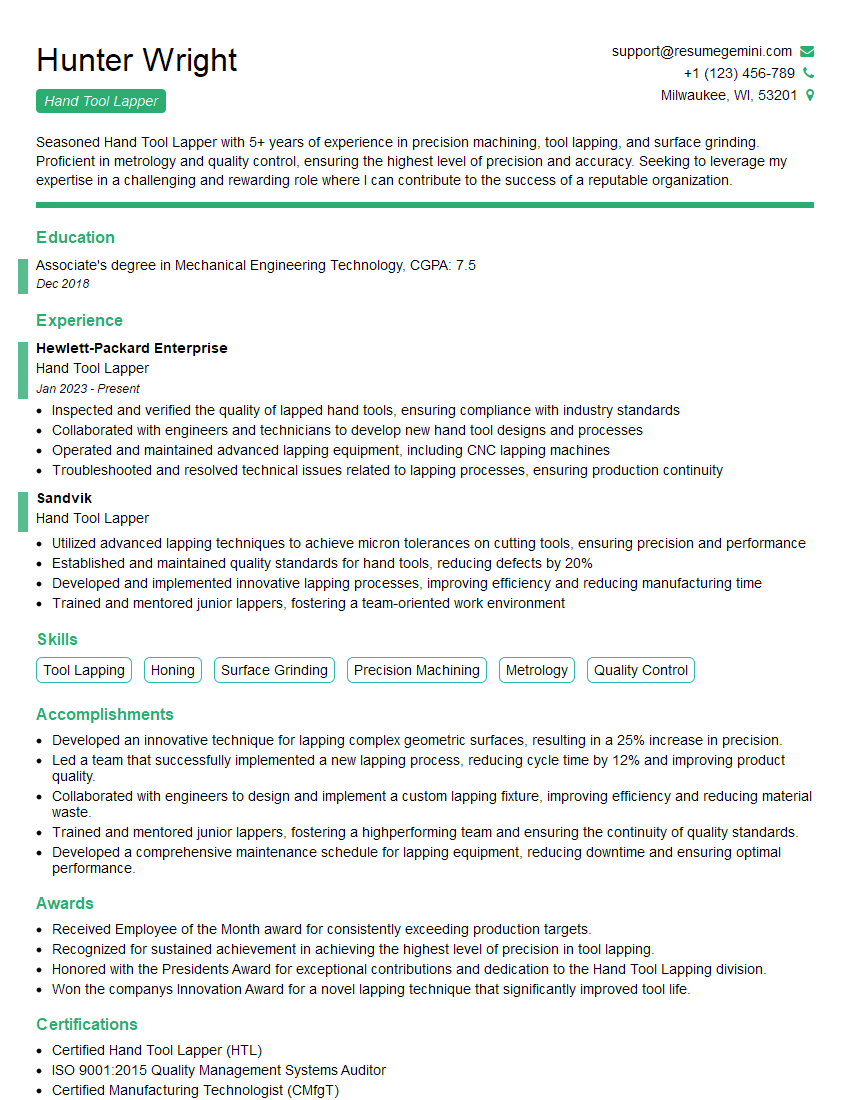

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hand Tool Lapper

1. What are the different types of hand tools used in lapping?

- Abrasive stones

- Lapping plates

- Honing sticks

- Buffing wheels

2. What are the different types of lapping compounds used?

Diamond compounds

- Used for hard materials such as carbide and ceramic

- Very abrasive and produce a fine finish

Boron nitride compounds

- Used for medium-hard materials such as steel and cast iron

- Less abrasive than diamond compounds and produce a smoother finish

Aluminum oxide compounds

- Used for soft materials such as aluminum and copper

- Least abrasive and produce a rougher finish

3. What are the different techniques used in hand lapping?

- Stroking

- Circular motion

- Figure-eight motion

4. What are the critical factors to consider when selecting a lapping compound?

- Material of the workpiece

- Desired surface finish

- Production volume

- Cost

5. What are the common defects that can occur during hand lapping?

- Scratches

- Grooves

- Burnishing

- Pitting

6. What are the safety precautions that must be taken when hand lapping?

- Wear eye protection

- Wear gloves

- Use a dust mask

- Ensure proper ventilation

7. What are the advantages of hand lapping over other lapping methods?

- Lower cost

- Greater flexibility

- Ability to lap complex shapes

8. What are the disadvantages of hand lapping over other lapping methods?

- Slower process

- Less consistent results

- Higher labor costs

9. What are the trends in hand lapping technology?

- Use of new materials and abrasives

- Development of automated hand lapping machines

- Increased focus on precision and quality control

10. What are the career opportunities for hand tool lappers?

- Production lapper

- Tool and die maker

- Quality control inspector

- Sales representative

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hand Tool Lapper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hand Tool Lapper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Hand Tool Lappers are responsible for the precision finishing of metal components using abrasive hand tools. They work in a variety of industries, including automotive, aerospace, and medical device manufacturing. Key job responsibilities include:

1. Deburring

Removing sharp edges from metal components using hand tools such as files, burrs, and scrapers.

- Ensuring that components meet specified surface finish requirements.

- Using a variety of hand tools to achieve the desired results.

2. Polishing

Improving the surface finish of metal components using hand tools such as polishing stones, abrasives, and buffing wheels.

- Achieving a high degree of surface finish for aesthetic or functional purposes.

- Using a variety of polishing techniques to achieve the desired results.

3. Grinding

Removing material from metal components using hand tools such as grinders and abrasive stones.

- Ensuring that components meet specified dimensional requirements.

- Using a variety of grinding techniques to achieve the desired results.

4. Lapping

Producing a very fine surface finish on metal components using abrasives and a lapping machine.

- Ensuring that components meet tight tolerances.

- Using a variety of lapping techniques to achieve the desired results.

Interview Tips

To ace an interview for a Hand Tool Lapper position, it is important to:

1. Research the company and the position

Learn as much as you can about the company’s products, services, and culture. Also, be sure to review the job description carefully and identify the key requirements.

- visit the company’s website and social media pages.

- Read industry publications and news articles.

2. Practice your answers to common interview questions

Think about the questions that you are likely to be asked in an interview and prepare your answers in advance. Common interview questions include:

- “Tell me about your experience in hand tool lapping.”

- “What are your strengths and weaknesses as a Hand Tool Lapper?”

- “Why are you interested in this position?”

3. Dress professionally and arrive on time

First impressions matter, so it is important to dress appropriately for an interview. Also, be sure to arrive on time and be prepared to answer questions about your punctuality.

- Wear clean and ironed clothes.

- Arrive 10-15 minutes early.

4. Be enthusiastic and positive

Employers want to hire people who are enthusiastic about their work. So, be sure to show your passion for hand tool lapping during your interview. Also, be positive and upbeat throughout the interview process.

- Smile and make eye contact.

- Speak clearly and confidently.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Hand Tool Lapper role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.