Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Handbag Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

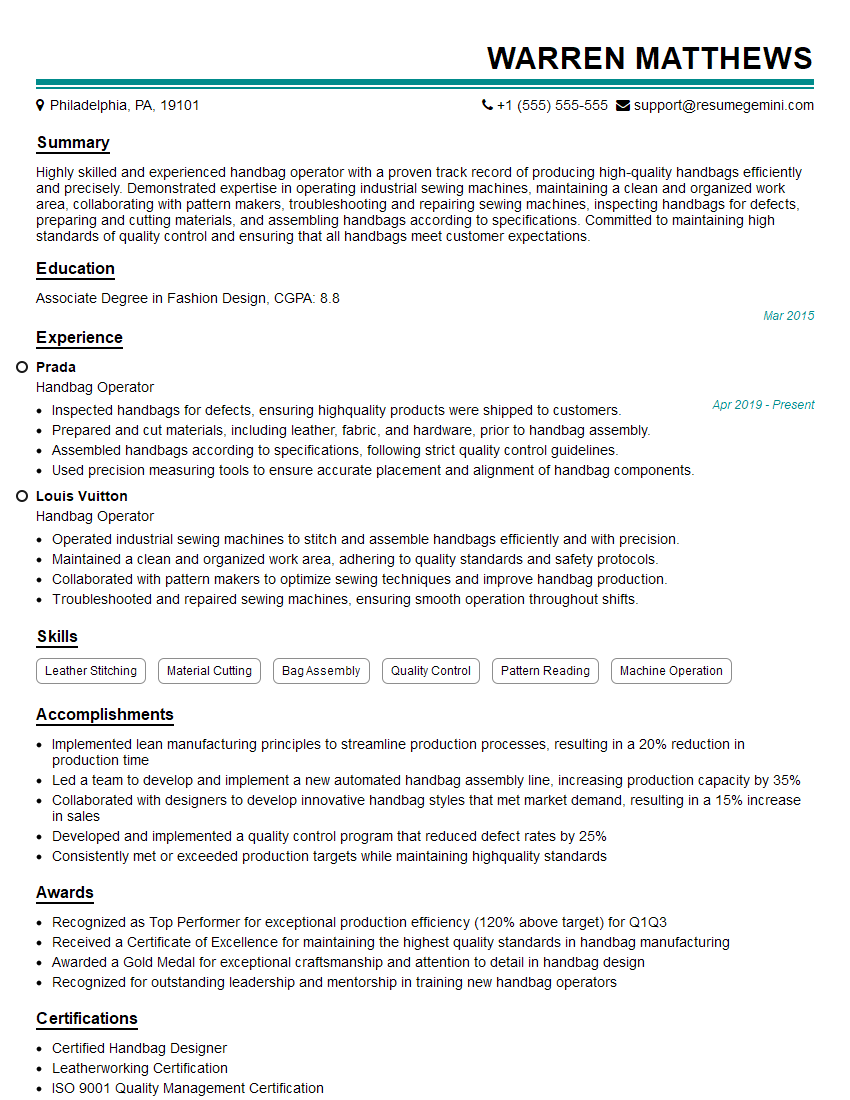

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Handbag Operator

1. What are the different types of sewing machines used in handbag manufacturing?

There are several types of sewing machines used in handbag manufacturing, each suited for specific tasks:

- Single-needle lockstitch machines: Used for general sewing, attaching straps, and closing bags.

- Double-needle lockstitch machines: Used for top stitching and decorative seams.

- Zigzag machines: Used for creating decorative edges and finishing seams.

- Thread trimmer machines: Used for automatically trimming excess thread.

- Bar tacking machines: Used for reinforcing high-stress areas, such as handle attachments.

2. Describe the process of pattern making for handbags.

Pattern Development

- Determine bag shape and dimensions.

- Create sketches and technical drawings.

- Calculate material requirements and seam allowances.

Pattern Grading

- Create multiple pattern sizes to cater to different bag sizes.

- Adjust dimensions and seam allowances accordingly.

Pattern Layout and Cutting

- Place patterns on fabric efficiently to minimize waste.

- Cut fabric pieces using sharp cutting tools.

3. What are the most important factors to consider when selecting materials for handbag construction?

When selecting materials for handbag construction, the following factors should be considered:

- Durability: Materials must withstand wear and tear, such as leather, nylon, and canvas.

- Aesthetics: Materials should complement the design and style of the bag.

- Functionality: Materials should be appropriate for the intended use of the bag, such as water-resistant for rain protection.

- Cost: Materials should meet quality standards while staying within budget.

- Sustainability: Environmentally friendly materials, such as recycled or vegan leather, are becoming increasingly important.

4. What are the common types of metal hardware used in handbag construction and their functions?

Common types of metal hardware used in handbag construction include:

- Zippers: Allow for easy opening and closing of bags.

- Buckles and clasps: Secure bag openings and add decorative elements.

- Rings and D-rings: Used for attaching straps and accessories.

- Studs and rivets: Reinforce stress points and add decorative accents.

- Chains and handles: Provide functionality and style.

5. What are the quality control procedures involved in handbag production?

Quality control procedures in handbag production include:

- Material inspection: Checking fabric, leather, and hardware for defects.

- Pattern verification: Ensuring that patterns meet specifications.

- Sewing inspection: Verifying stitch consistency and seam strength.

- Hardware attachment inspection: Checking for secure and proper hardware placement.

- Final product inspection: Assessing overall quality, aesthetics, and functionality.

6. Describe the process of attaching a zipper to a handbag.

Zipper Preparation

- Determine the optimal zipper length and style.

- Measure and mark the zipper placement.

Fabric Preparation

- Cut and sew fabric to create the zipper opening.

Zipper Attachment

- Position the zipper under the fabric and pin it in place.

- Sew the zipper using a zipper foot to ensure even stitching.

Finishing

- Conceal the zipper teeth using fabric or trim.

- Add a zipper pull for easy opening and closing.

7. How do you handle complex sewing techniques, such as curved seams or decorative stitching?

Curved Seams

- Use a pivoting foot or sliding plate to navigate curves smoothly.

- Take small, even stitches to prevent puckering.

Decorative Stitching

- Select appropriate thread and stitch settings for decorative effects.

- Use a free-motion foot to achieve intricate patterns.

- Practice on scrap fabric before applying to the actual piece.

8. Describe your experience in working with different types of leather for handbag construction.

I have experience working with various types of leather for handbag construction, including:

- Full-grain leather: Durable, natural leather with visible grain patterns.

- Top-grain leather: Split from the top layer of the hide, providing a smooth and uniform appearance.

- Split leather: Made from the lower layers of the hide, offering a suede-like texture at a lower cost.

- Bonded leather: A combination of leather scraps and synthetic fibers, resulting in a durable and affordable option.

- Exotic leathers: From animals such as snakes, ostriches, or alligators, offering unique textures and patterns.

9. What are the challenges and solutions associated with working with delicate or textured fabrics in handbag manufacturing?

Challenges

- Tearing: Delicate fabrics require careful handling and precise sewing.

- Puckering: Textured fabrics can pucker if not sewn with the correct tension.

- Slippage: Some materials, such as silk, can slip under the needle.

Solutions

- Specialized needles: Microtex or stretch needles prevent tearing.

- Appropriate stitch settings: Adjust tension and stitch length to suit delicate fabrics.

- Interfacing: Add a layer of interfacing to stabilize fabrics and prevent puckering.

- Pressing: Gently press seams to reduce slippage and improve fabric handling.

10. Share an example of a creative solution you implemented to overcome a production issue in handbag manufacturing.

In one instance, we faced a problem with thread breaking during the stitching of a particular handbag design. The fabric was a delicate silk that required a specific thread type and tension.

- Issue Analysis: I examined the thread, needle, and machine settings to identify the cause of the breakage.

- Solution: I tested different thread types and adjusted the machine tension accordingly. I also used a microtex needle designed for delicate fabrics.

- Outcome: The adjustments prevented thread breakage and ensured smooth stitching, resulting in a high-quality finish.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Handbag Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Handbag Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Handbag Operator is responsible for operating machines and equipment to produce handbags. The key roles and responsibilities of a Handbag Operator include:

1. Handbag Production

The primary responsibility of a Handbag Operator is to operate machines efficiently to cut, stitch, assemble, and finish handbags according to specifications. This includes:

- Setting up and operating sewing machines.

- Cutting leather or fabric using specialized tools.

- Stitching and assembling different parts of the handbag.

- Attaching hardware (e.g. zippers, buckles)

- Finishing the handbags by pressing and inspecting.

2. Quality Assurance

Handbag Operators are responsible for maintaining quality standards throughout the production process. This involves checking the quality of materials and ensuring that the handbags meet customer specifications. They may also be involved in the inspection of finished products before they are shipped out.

- Inspecting raw materials (e.g. leather, fabric)

- Checking the quality of stitching and assembly

- Ensuring that handbags meet design specifications

- Identifying and correcting defects

3. Maintenance and Troubleshooting

Handbag Operators are often responsible for basic maintenance of the equipment they use. This may include:

- Cleaning and lubricating machines

- Troubleshooting and resolving minor issues

- Reporting major issues to supervisors

4. Health and Safety

Handbag Operators must adhere to safety regulations and wear appropriate protective gear while operating machinery. They must also maintain a clean and organized work area to prevent accidents and injuries.

- Following safety procedures

- Wearing protective gear

- Maintaining a clean and organized workspace

- Reporting any hazards or unsafe conditions

Interview Tips

By understanding the key job responsibilities of a Handbag Operator, candidates can prepare effectively for their interviews. Here are some additional tips that can help candidates ace the interview:

1. Research the company and the role

Familiarize yourself with the company’s history, products, and values, as well as the specific requirements of the Handbag Operator role. This will enable you to answer questions intelligently and demonstrate your interest in the position.

2. Highlight your relevant skills and experience

Emphasize your skills and experience in operating sewing machines, cutting and stitching materials, and assembling and finishing handbags. Quantify your accomplishments whenever possible to showcase your impact on previous roles.

3. Be prepared to discuss quality assurance

Explain your understanding of quality assurance standards and how you ensure the quality of your work. Provide examples of how you have identified and corrected defects in the past.

4. Demonstrate your commitment to safety

Emphasize your commitment to safety by discussing your experience following safety procedures and maintaining a clean and organized workspace. Mention any safety training or certifications you have obtained.

5. Prepare questions for the interviewer

Asking thoughtful questions at the end of the interview shows that you are engaged and interested in the role. Prepare questions about the company, the team, and the challenges and opportunities of the Handbag Operator position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Handbag Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.