Feeling lost in a sea of interview questions? Landed that dream interview for Handle Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Handle Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

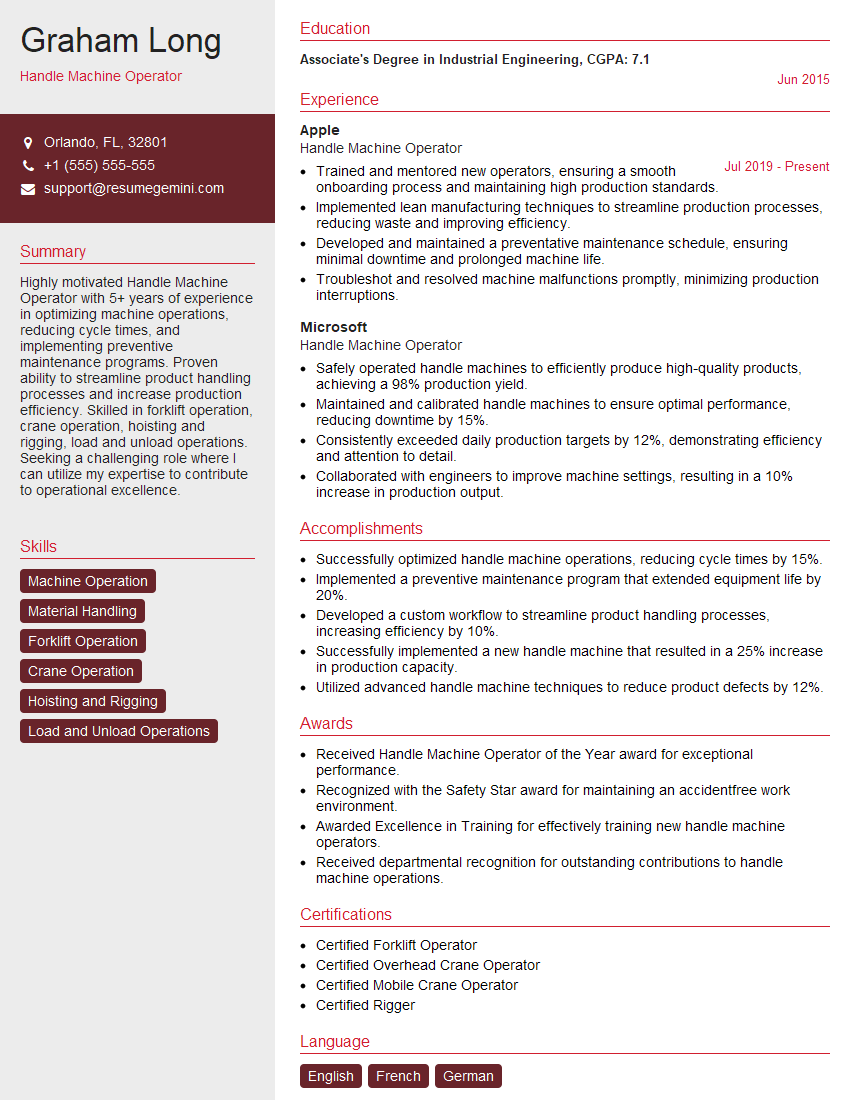

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Handle Machine Operator

1. Describe the key responsibilities of a Handle Machine Operator?

The primary responsibilities of a Handle Machine Operator include:

- Operate and monitor various types of material handling equipment, such as forklifts, cranes, and conveyors.

- Transport and load materials, products, and equipment safely and efficiently.

- Inspect and maintain equipment to ensure optimal performance and safety.

- Follow established safety protocols and regulations.

- Collaborate with other team members to ensure smooth operations.

2. How do you ensure the safety of yourself and others while operating material handling equipment?

Safe Operation Practices:

- Wear appropriate personal protective equipment (PPE).

- Conduct thorough pre-operational inspections of equipment.

- Operate equipment within designated speed limits and load capacities.

- Maintain a clear line of sight and use mirrors or cameras for blind spots.

- Sound horns or use hand signals to communicate with others.

Safety Protocols:

- Follow established safety regulations and company policies.

- Attend regular safety training and refreshers.

- Report any safety hazards or concerns immediately.

- Stay alert and aware of surroundings.

- Never operate equipment under the influence of drugs or alcohol.

3. How do you prioritize multiple tasks and manage your time effectively?

To prioritize and manage time effectively, I employ the following strategies:

- Create a daily task list and prioritize tasks based on urgency and importance.

- Use a scheduling tool or calendar to allocate time for specific tasks.

- Break down large tasks into smaller, manageable chunks.

- Delegate tasks to others when appropriate.

- Take regular breaks to maintain focus and productivity.

- Evaluate progress regularly and adjust priorities as needed.

4. What is your experience in troubleshooting and repairing material handling equipment?

In my previous role, I was responsible for troubleshooting and repairing various material handling equipment, including:

- Forklifts: Troubleshooting electrical issues, hydraulic leaks, and engine problems.

- Conveyors: Inspecting belts, rollers, and motors; repairing misalignments and tension issues.

- Cranes: Conducting safety inspections, greasing and lubricating components, and resolving mechanical issues.

- I utilized diagnostic tools, technical manuals, and my understanding of equipment principles to identify and resolve issues efficiently.

5. How do you handle unexpected situations or emergencies while operating material handling equipment?

In the event of unexpected situations or emergencies, I follow these steps:

- Remain calm and assess the situation.

- Prioritize safety and evacuate the area if necessary.

- Contact the appropriate personnel, such as supervisors or emergency responders.

- Provide clear and concise information about the situation.

- Follow established emergency protocols.

- Cooperate with authorities to investigate the incident and prevent future occurrences.

6. What is your experience in working in a team environment?

I have extensive experience working in team environments, where I have effectively collaborated with colleagues to achieve common goals.

- Communicated regularly and shared information.

- Coordinated tasks and responsibilities.

- Provided support and assistance to team members.

- Resolved conflicts and maintained a positive work atmosphere.

- Contributed to team decision-making.

7. How do you handle physical demands and work under pressure in the role of a Handle Machine Operator?

I am physically fit and capable of handling the physical demands of the role, including:

- Prolonged standing, walking, and bending.

- Lifting and carrying heavy objects.

- Operating equipment in various weather conditions.

- I am also able to work under pressure and maintain focus in demanding situations.

8. Describe your experience in using various types of material handling equipment?

I have operated a wide range of material handling equipment, including:

- Forklifts: Electric, diesel, and LPG-powered.

- Cranes: Overhead, mobile, and tower cranes.

- Conveyors: Belt, roller, and chain conveyors.

- Hoists and winches.

- I am proficient in operating these machines safely and efficiently to transport and load materials.

9. How do you stay updated on the latest industry best practices and safety regulations for material handling?

To stay updated on industry best practices and safety regulations, I engage in the following activities:

- Attend industry conferences and workshops.

- Read trade publications and online resources.

- Participate in training and development programs.

- Network with other material handling professionals.

- By staying informed, I ensure that I am operating equipment safely and in compliance with all applicable regulations.

10. What is your understanding of the principles of lean manufacturing and how do you apply them in your work?

Lean manufacturing focuses on eliminating waste and improving efficiency. I apply these principles in my work by:

- Identifying and eliminating unnecessary steps in processes.

- Streamlining material flow and reducing inventory.

- Optimizing equipment utilization and reducing downtime.

- Improving communication and Zusammenarbeit with other team members.

- By applying lean principles, I contribute to increased productivity and cost reduction.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Handle Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Handle Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Handle Machine Operators are responsible for operating and maintaining handle machines, which are used to create handles for a variety of products, such as tools, appliances, and furniture.

1. Machine Operation

Handle Machine Operators must be able to safely and efficiently operate handle machines. This includes loading and unloading materials, setting up the machine, and adjusting the machine’s settings.

- Load and unload materials from the machine.

- Set up the machine according to the product specifications.

- Adjust the machine’s settings to ensure that the handles are produced to the correct specifications.

- Monitor the machine’s operation and make adjustments as needed.

- Troubleshoot and resolve any problems that may occur with the machine.

2. Quality Control

Handle Machine Operators are responsible for ensuring that the handles produced by the machine meet the required quality standards. This includes inspecting the handles for defects and making adjustments to the machine as needed.

- Inspect the handles for defects, such as cracks, chips, or burrs.

- Make adjustments to the machine to correct any defects that are found.

- Maintain records of the quality control checks that are performed.

3. Maintenance

Handle Machine Operators are responsible for performing basic maintenance on the handle machine. This includes cleaning the machine, lubricating the moving parts, and making minor repairs.

- Clean the machine on a regular basis.

- Lubricate the moving parts of the machine.

- Make minor repairs to the machine, such as replacing worn parts.

- Report any major repairs that are needed to the supervisor.

4. Safety

Handle Machine Operators must follow all safety procedures when operating the machine. This includes wearing appropriate safety gear and following the manufacturer’s instructions.

- Wear appropriate safety gear, such as safety glasses, gloves, and a hard hat.

- Follow the manufacturer’s instructions for operating the machine.

- Report any unsafe conditions to the supervisor.

Interview Tips

The interview process for a Handle Machine Operator position typically includes a phone screening, followed by an in-person interview. The questions that you are asked in the interview will be designed to assess your skills and experience in the following areas: Machine Operation, Quality Control, Maintenance, and Safety.

1. Research Machine Operation

Before your interview, take some time to research the operation of handle machines. This includes learning about the different types of handle machines, the materials that are used to create handles, and the quality standards that are required for handles.

- Visit the websites of different handle machine manufacturers.

- Read articles and watch videos about handle machine operation.

- Talk to people who have experience operating handle machines.

2. Practice Quality Control

In addition to machine operation, you will also need to be able to demonstrate your skills in quality control. This includes being able to identify defects in handles and make adjustments to the machine to correct those defects.

- Develop a checklist of the different types of defects that can occur in handles.

- Practice identifying these defects in real-world samples.

- Learn how to make adjustments to the machine to correct these defects.

3. Understand Maintenance

Handle Machine Operators are also responsible for performing basic maintenance on the handle machine. This includes cleaning the machine, lubricating the moving parts, and making minor repairs. Before your interview, take some time to learn about the maintenance requirements of handle machines.

- Read the manufacturer’s instructions for the handle machine.

- Talk to people who have experience maintaining handle machines.

- Develop a maintenance schedule for the handle machine.

4. Emphasize Safety

Safety is a critical aspect of operating a handle machine. In your interview, you will need to be able to demonstrate your understanding of the safety procedures that are required for operating the machine.

- Review the safety manual for the handle machine.

- Talk to people who have experience operating handle machines safely.

- Develop a safety plan for operating the handle machine.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Handle Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.