Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Handle Maker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

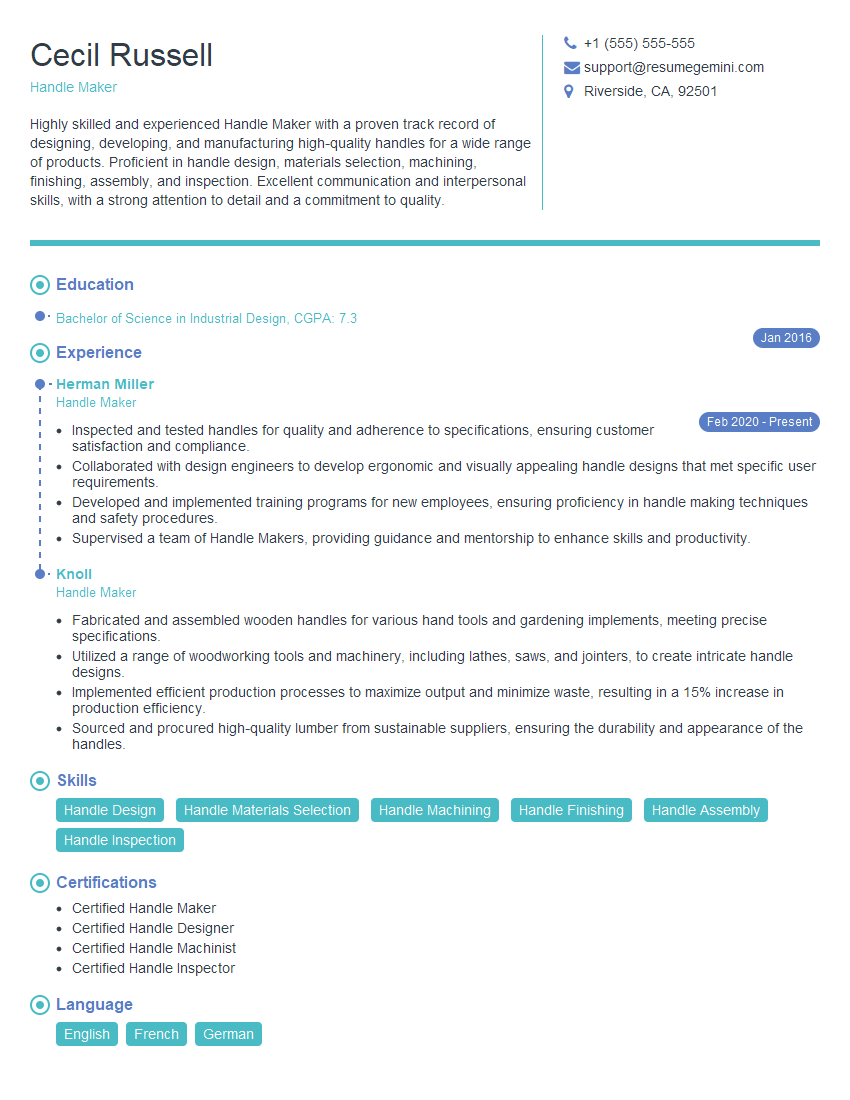

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Handle Maker

1. What are the different types of handles you have experience in making?

In my previous role, I was responsible for creating a wide range of handles, including:

- Wooden handles for tools and furniture

- Metal handles for machinery and equipment

- Plastic handles for consumer products

- Composite handles for specialized applications

2. What are the key factors to consider when designing a handle?

Ergonomics

- The handle should fit comfortably in the user’s hand

- It should be easy to grip and manipulate

- The weight and balance of the handle should be appropriate for the intended use

Material selection

- The material should be strong and durable

- It should be resistant to wear and tear

- The material should be aesthetically pleasing

Manufacturing process

- The manufacturing process should be efficient and cost-effective

- It should produce high-quality handles that meet the required specifications

3. What are the different methods you use to create handles?

I use a variety of methods to create handles, depending on the material and the desired shape:

- Turning: I use a lathe to shape wooden and metal handles

- Milling: I use a milling machine to create complex shapes in metal handles

- Injection molding: I use an injection molding machine to create plastic handles

- Casting: I use a casting process to create metal handles with intricate designs

4. What is your experience with using CNC machines?

I have extensive experience using CNC machines to create handles. I am proficient in:

- Programming CNC machines to create complex shapes

- Operating CNC machines safely and efficiently

- Maintaining and repairing CNC machines

5. What are your strengths and weaknesses as a handle maker?

Strengths:

- I have a strong understanding of the principles of handle design and manufacturing

- I am skilled in using a variety of methods to create handles

- I am a creative and innovative thinker

- I am a hard worker and I am always willing to learn new things

Weaknesses:

- I am sometimes too perfectionistic

- I can be impatient at times

6. What is your favorite type of handle to make?

My favorite type of handle to make is a wooden handle. I enjoy the challenge of working with wood and creating a beautiful and functional object.

7. What is the most challenging handle you have ever made?

The most challenging handle I have ever made was a metal handle for a piece of heavy machinery. The handle had a complex shape and it was difficult to achieve the desired finish.

8. What are your career goals?

My career goal is to become a master handle maker. I want to continue to learn new techniques and develop my skills so that I can create beautiful and functional handles that are used by people all over the world.

9. Do you have any questions for me?

I would like to know more about the company and the position. I am also interested in learning about the company’s commitment to quality and innovation.

10. What are your salary expectations?

My salary expectations are commensurate with my experience and skills. I am confident that I can make a valuable contribution to your company.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Handle Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Handle Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Handle Maker is responsible for crafting and shaping handles for various tools, utensils, and other objects. This role requires expertise in woodworking, knowledge of different materials, and an eye for detail. Key job responsibilities include:

1. Crafting Handles

Using specialized tools and equipment, handle makers create handles for axes, knives, hammers, and other handheld tools. They ensure that the handles are ergonomically designed, provide a secure grip, and meet the specific requirements of each tool.

- Selecting and preparing raw materials, such as wood, metal, or plastic.

- Shaping and forming handles using saws, lathes, or other woodworking tools.

2. Finishing and Polishing

Handle makers apply various techniques to enhance the appearance and durability of the handles. They may sand, stain, or paint the handles, and apply protective finishes to prevent wear and tear.

- Applying finishes to protect the handles from moisture, chemicals, or abrasion.

- Polishing handles to achieve a smooth, aesthetically pleasing surface.

3. Assembly and Inspection

Once the handles are crafted and finished, handle makers assemble them with the corresponding tools or objects. They also inspect the final products for quality and accuracy.

- Attaching handles to tools or utensils using adhesives, screws, or other fasteners.

- Inspecting the finished products for defects, such as cracks, splinters, or uneven surfaces.

4. Maintaining Equipment and Workspace

Handle makers are responsible for maintaining their workspaces and equipment, ensuring that all tools and machinery are functioning properly and safely.

- Cleaning and maintaining tools and equipment to prevent accidents and ensure efficient operation.

- Keeping the workspace organized and free of clutter to promote productivity and safety.

Interview Tips

Preparing thoroughly for a Handle Maker interview is crucial. Here are some tips to help you ace the interview:

1. Research the Company and Position

Familiarize yourself with the company’s history, products/services, and culture. Understanding the specific requirements of the Handle Maker position will enable you to tailor your answers accordingly.

- Visit the company’s website and social media pages.

- Read industry news and articles to stay updated on the latest trends in handle making.

2. Practice Your Answers

Anticipate common interview questions and prepare your responses. Practice speaking confidently and concisely, highlighting your relevant skills and experience.

- Prepare examples of projects where you demonstrated your woodworking skills.

- Discuss your knowledge of different handle materials and their applications.

3. Highlight Your Passion

Handle making requires precision, creativity, and an appreciation for craftsmanship. Convey your genuine interest in the field and demonstrate your eagerness to learn and grow.

- Share your personal projects or hobbies related to woodworking or design.

- Express your enthusiasm for creating functional and aesthetically pleasing handles.

4. Be Prepared to Showcase Your Skills

If possible, bring a portfolio or examples of your work to the interview. This will provide tangible evidence of your abilities and craftsmanship.

- Present samples of handles you have crafted.

- Bring sketches or designs that demonstrate your creativity and understanding of handle ergonomics.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Handle Maker interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.