Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Hard Rock Miner, Blasting position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

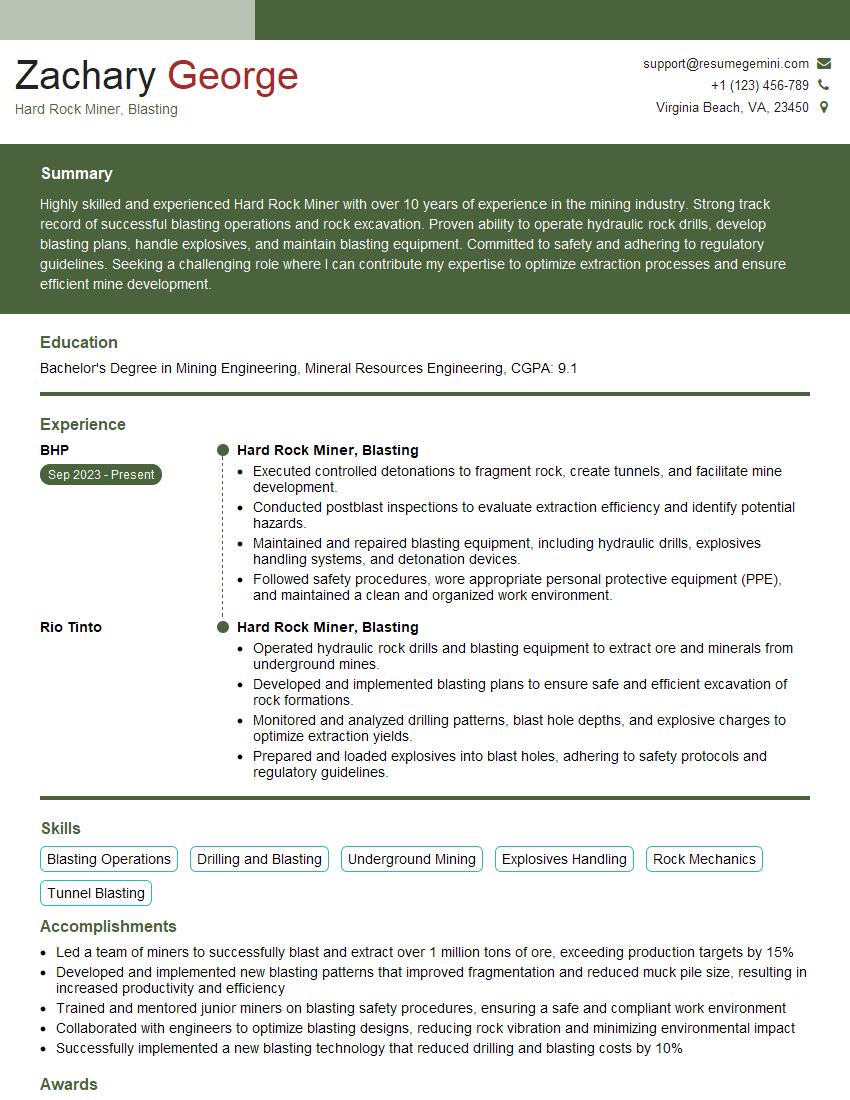

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hard Rock Miner, Blasting

1. Explain the different types of explosives used in hard rock mining and blasting. Describe the properties and applications of each type.

- Ammonium Nitrate Fuel Oil (ANFO): A blend of ammonium nitrate and diesel fuel, commonly used in large-diameter blastholes for its low cost and high energy output.

- Emulsion Explosives: A water-in-oil emulsion, offering high energy density and reduced fumes compared to ANFO.

- Dynamite: A high explosive containing nitroglycerin, known for its shock sensitivity and relatively low energy compared to modern explosives.

2. Describe the factors that influence the selection of drilling patterns and hole diameters for blasting.

Hole Diameter Selection

- Rock strength and abrasiveness

- Explosive energy and charge density

- Drill hole depth

Drilling Pattern Selection

- Rock properties (hardness, jointing, etc.)

- Desired fragmentation size

- Ground conditions (water table, seismic sensitivity)

3. Discuss the safety measures that must be implemented during blasting operations.

Pre-Blast:

- Site clearance and exclusion zone establishment

- Warning signals and communication systems

- Ground vibration and airblast monitoring

During Blasting:

- Proper blasting cap alignment and detonation sequence

- Controlled ignition and monitoring

- Emergency response plan in place

4. How do you determine the proper charge weight and spacing for a given blast?

- Calculate rock mass characteristics (density, strength)

- Estimate energy requirements based on fragmentation size

- Use empirical formulas or blasting software to determine charge weight

- Adjust spacing based on hole depth and rock properties

5. Explain the principles of rock fragmentation and how they apply to blasting.

Stress Wave Propagation:

- Explosives create high-pressure shock waves that travel through rock.

- Waves reflect and interact, creating tensile and shear stresses.

Fragmentation:

- Stress waves weaken and fracture the rock matrix.

- Fragment size is influenced by factors such as energy density, rock properties, and drilling pattern.

6. Describe the different methods for evaluating blast results.

- Visual Inspection: Assessment of fragmentation size and distribution.

- Sieve Analysis: Measuring the particle size distribution to determine fragmentation efficiency.

- Vibration Monitoring: Evaluating ground vibrations to assess potential damage to structures.

7. How do you optimize blasting operations to minimize environmental impact?

- Reduced Charge Density: Using lower explosive charges to minimize vibration and airblast.

- Proper Timing and Sequencing: Staggering blasts to reduce cumulative impacts.

- Dust Control Measures: Implementing dust suppression systems and water barriers.

8. Explain the role of explosives engineers in hard rock mining.

- Design and plan blasting operations to meet production and environmental goals.

- Monitor and evaluate blast results to optimize performance and mitigate risks.

- Train and supervise blasting crews to ensure safety and compliance.

9. Describe the different types of blasting machines used in hard rock mining.

- Electrical Blasting Machines: Generate high-voltage pulses to initiate electric caps.

- Nonelectric Blasting Machines: Utilize electronic signals to initiate nonel tubes or detonating cords.

- Radio Remote Control Systems: Wirelessly initiate blasts from a safe distance.

10. Discuss the challenges and advancements in hard rock blasting technology.

Challenges:

- Ensuring safety and minimizing environmental impact.

- Optimizing fragmentation for specific applications.

Advancements:

- Development of electronic detonators and blasting software.

- Application of 3D modeling and simulation for blast design.

- Use of drones and sensors for blast monitoring.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hard Rock Miner, Blasting.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hard Rock Miner, Blasting‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Hard Rock Miners, Blasting play a crucial role in mining operations, specializing in extracting valuable minerals from hard rock formations through the use of explosives. Their primary responsibilities include:

1. Planning and Execution of Blasts

Plan and design drill patterns for blasting operations, ensuring optimal fragmentation and safety.

- Calculate charge weights, delay patterns, and stemming requirements.

- Load and detonate explosives safely and accurately.

2. Drilling and Rock Breaking

Operate drilling equipment to create boreholes for blasting.

- Repair and maintain drilling equipment, ensuring optimal performance.

- Break and remove large rocks using hydraulic splitters or wedge systems.

3. Safety and Regulations Compliance

Adhere to all safety protocols and regulations related to blasting and mining operations.

- Inspect and maintain equipment, ensuring it meets safety standards.

- Follow proper procedures for handling and storing explosives.

4. Communication and Teamwork

Effectively communicate with other miners, engineers, and supervisors to coordinate blasting operations.

- Participate in safety briefings and meetings to discuss procedures and potential hazards.

- Collaborate with other team members to ensure efficient and safe work practices.

Interview Tips

With the right preparation, you can increase your chances of success in a Hard Rock Miner, Blasting interview. Here are some valuable tips to help you ace it:

1. Research the Company and Position

Gain a thorough understanding of the mining company and the specific role you are applying for. This will demonstrate your interest and enthusiasm for the opportunity.

- Visit the company’s website and social media pages.

- Read industry publications and articles to stay informed about the latest mining technologies and best practices.

2. Practice Common Interview Questions

Prepare for common interview questions related to your experience, skills, and qualifications. Practice answering them clearly and concisely, highlighting your strengths and how you align with the job requirements.

- Describe your experience with planning and executing blasting operations.

- How do you ensure safety and compliance in your work?

- Tell us about a challenging mining project you have worked on and how you overcame it.

3. Highlight Your Technical Skills

Emphasize your technical knowledge and skills in drilling, blasting, and rock breaking. Provide specific examples of your experience using specialized equipment and techniques.

- Discuss your expertise in handling and detonating explosives.

- Describe your understanding of different blasting agents and their applications.

4. Showcase Your Safety Mindset

Mining operations inherently involve safety risks. Demonstrating your commitment to safety will be highly valued by potential employers. Highlight your knowledge of safety protocols and regulations, and emphasize your ability to work safely and efficiently.

- Explain how you identify and mitigate safety hazards in your work.

- Share your experience in conducting safety inspections and training.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Hard Rock Miner, Blasting interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.